Carbondioxide Scrubbers for rebreathers

This article on scrubbers describes only part of the current knowledge on carbon dioxide absorbing systems. These descriptions cover scrubbers for breathing systems in mining as well as systems for underwater use. Oxygen rebreathers are generally not used for deep diving but mainly for prolonged shallow dives. The data presented here is a cross section of information on these systems in no particular order.

Rebreathers have the special feature of removing carbon dioxide from the gas used, which is produced by human metabolism. The amount of carbon dioxide does not depend on the depth of the dive but only on the amount of work done. This carbon dioxide must be removed from the exhaled gas. In 1771, Carl Wilhelm Scheele discovered that Oxygen was the gas that enabled humans and animals to live. Not long after, he experimented with products to capture the CO2, which he succeeded in 1777 during animal experiments. After many trials and research, Soda-Lime was finally patented in 1930 by Charles A. Carey of Arlington Massachusetts USA.

A scrubber in good working order is tested. Making a scrubber yourself is technically not very complex, but to realise an optimal gas absorption and duration of use of a scrubber requires extensive testing. These tests are expensive and technically very complex.

In the photo above you can see a unique set-up for testing rebreathers. Ambient Pressure Diving gave me permission to release this photo. With thanks to Martin Parker Director of A P Diving. The picture shows an ANSTI test facility for testing rebreathers in realistically simulated conditions.

It was the first 200m chamber ANSTI built. At 1m internal diameter it will take a rebreather in any attitude. It maintains the water temperature at anything between -2C (with additives) and 34C. Normally it’s kept at 3C.

The associated breathing machine can breathe at 10 lpm to 134 lpm. The associated mass flow controllers add CO2 for testing scrubber durations under the different conditions and add inert gas to facilitate oxygen uptake. It has inlet and exhaust valves which allow us to ascend/descend at varying speeds. The external gas analysers are used to verify the performance of the rebreather and the accuracy of its measurement and displays. This 200m ANSTI rig allows us to test rebreathers over long periods under extreme usage and environmental conditions far exceeding what is achievable with manned testing.

Since this, ANSTI have supplied 200m rigs to Kirby Morgan, the Swedish and French Navies.

Scrubbers are made in 2 main types, axial and radial types. With the axial scrubber, the gas is passed through the scrubber in an axial direction. With radial scrubbers, the gas is led from the outside inwards in an annular scrubber, or in some rebreathers from the core outwards.

Axial scrubbers have a longer ‘bed’, so that the gas has a long contact with the lyme. The advantage of a long bed is that good scrubbing can be achieved through long contact between the gas and the lyme granules. The disadvantage is that with increasing bed length the breathing resistance will also increase.

Radial scrubbers have a shorter bed and thus lower breathing resistance.

Both radial and axial scrubbers can settle due to movement of the lyme, i.e. space can be created between the housing and the lyme. For this reason, in addition to a skim filter, a spring package is also used that presses a plate on top of the lyme. This pressure plate ensures that any settling is compensated for and the lyme continues to function properly as a mass.

There is a lively discussion about the most efficient design. By far the most rebreathers use an axial scrubber. The reason for this is primarily that the most commonly sold scrubber is an axial scrubber, but also that the seals on axial scrubbers are of a simple construction.

Axial scrubbers used in diving systems are relatively simple in design, but have a number of disadvantages compared to radial scrubbers. When the scrubber is filled, it has to be tapped (vibrated or shaken), so that the lyme can be compacted up to 10%. This should be done carefully before the dive. If this is not done carefully, the lyme can form a cavity as a result of settling, which could lead to a CO2 bypass in a certain position.

Water is an enemy of Lyme and entry must be prevented at all times. Most axial scrubbers have a gas inlet at the bottom of the bed, which can obstruct the breathing circuit when water enters. With radial scrubbers this problem is less, because the water can spread over a larger surface. The disadvantage of the radial scrubber is a much more complex construction, where only through trial and error the proper functioning can be determined during construction.

A survey of hundreds of rebreathers has shown that a rule of thumb is that one kilo of soda-lime suitable for the rebreather in question can provide one hour of dive time at a Co2 production of 1 l/min in 4 degrees water at a depth of 15 mtrs. As one dives deeper, the absorption efficiency of an axial scrubber decreases more than that of a radial scrubber. Many other factors can influence this absorption time negatively, and no certainty can be derived from this average value. It is an indication to give an idea what can be realised with soda-lime.

Each scrubber’s efficiency will depend very much on its form factor. This means that an axial scrubber will show a different efficiency when the length or diameter is changed. Also the choice of the Lime depends on many factors. Manufacturers always recommend a specific type of Lime for their certified rebreather because of the above factors.

Most types of lyme will develop dust by filling and moving. This fine dust will be released when gas is passed through. For this reason, most rebreathers include a fine filter in the circuit, usually in the form of a skim or fine filter.

The filling of scrubbers requires device-specific instructions. Often the lyme needs to be vibrated in order to become more compact and form a good filter bed. Not properly vibrating (tapping) can lead to a situation where CO2 bypass can occur. This will create passages through the filter bed allowing CO2 rich gas to leave the clean side of the scrubber and lead to CO2 poisoning or Hypercapnia.

The correct sealing between the CO2-rich supply side and the CO2-poor return side is usually realised with an O-ring. Correct placement, maintenance and greasing of this ring is of vital importance to ensure optimum sealing.

The use of half-fills in rebreathers originates from older oxygen systems where half-cartridges were offered. Applying this technique to a normal scrubber by using an improvised attachment is strongly discouraged. The manufacturer tests his rebreathers with the prescribed filling. Experimenting here is asking for accidents!

There was a period when an indicator was added to the lime – a colour change appeared, which was said to be a measure of the lime’s useful life. This technique has repeatedly proven unreliable for diving applications and is strongly discouraged. Colour Reversion is the expression used to describe the change in colour of depleted Sodasorb absorbent from purple to white when left to rest for a few hours or more. In the past, the term regeneration of soda lime has been incorrectly used to describe this process.

This colour change is the result of calcium hydroxide regenerating on the surface of the pellet. This changes the pH of the surface, causing the dye indicator to turn white again, even though Sodasorb adsorption is almost exhausted.

Soda lime does not regenerate. Instead, there is a reversal of the indicator colour from purple to white. Although there may be some additional carbon dioxide uptake due to the migration of these hydroxides, the absorption capacity of soda lime, previously saturated with CO2, is minimal and should not be relied upon even when the colour of the pellets has returned to white.

It is therefore important that, immediately after using Sodasorb absorbent, the user determines how much absorption capacity it still has. If Indicator Sodasorb is used, visual inspection can help determine the remaining absorption capacity. If you are not sure how much absorption capacity is left in the Sodasorb, you must change it. Carbon dioxide monitors and time and volume calculations should also be used to determine the remaining CO2 absorption capacity.

I often receive questions about the shelf life of sofnolime. A good practice is to stick to the duration of use as indicated by the manufacturer and not to keep a filled scrubber longer than two days in the rebreather. A scrubber with 2 hours of diving can be used on day 1 for one hour, and on day 2 for another hour. Personally, I prefer to keep the breathing loop closed to limit further gas exchange. It is of course better to replace the Sofnolime after every dive. Realize that the cost of a refill is in no way proportional to the cost of your diving trip, let alone your life!

Lyme disease comes in many shapes and sizes. My advice is to strictly adhere to the conditions set by the manufacturer in the instructions for use. The CE declaration on your rebreather is there for a reason. The manufacturer has to prove that the indicated duration of use (both on land and underwater) can be realised with the scrubber he supplies. This includes a specific type of lyme from which you must not deviate!

Sodasorb absorbent is a patented mixture of calcium hydroxide, sodium hydroxide and water. Hydroxides are used in the absorption of acid gases because they are efficient, stable and easy to handle. They are derived from alkalis and alkaline earth metals and are the most efficient absorbers of carbon dioxide available.

The absorption of carbon dioxide (CO2), or of any acidic gas, by Sodasorb absorbent is a chemical process, not a physical one. The reaction is very different from absorption by, for example, activated carbon, where gases are physically trapped.

In Sodasorb absorption, the CO2 first reacts with water to form carbonic acid, and then reacts with the hydroxide to form soluble salts of sodium carbonate. The soluble salts then react with the calcium hydroxide to form insoluble calcium carbonate. By-products are heat and water.

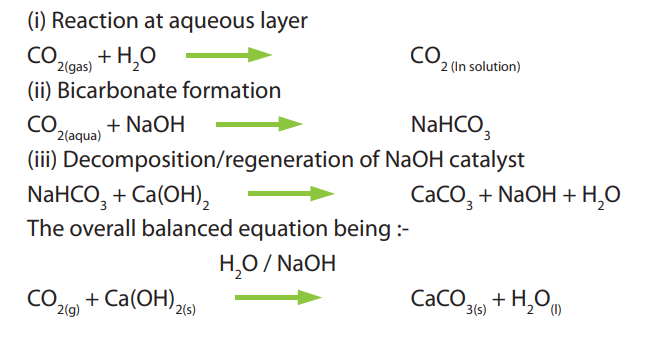

Neutralisation of CO2 by Sodasorb can be expressed by the following equations:

1. CO2(gas) +H2O < ——- > H2CO3

2. 2H2CO3+2NaOH < ——- > Na2CO3+4H2O+Heat

3. 2Ca(OH)2+Na2CO3 < ——- > 2CaCO3+2NaOH+Heat

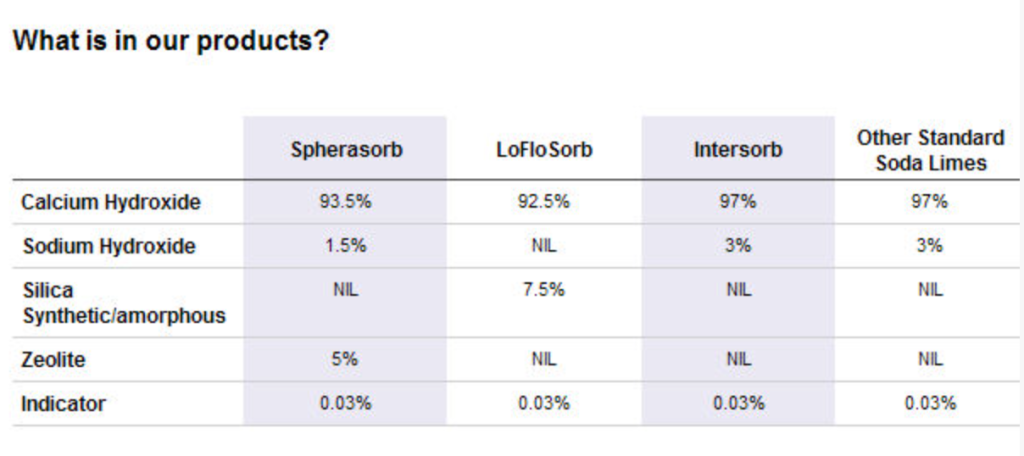

Some of the available types of lyme for diving applications

Lyme is marketed under different names, distinguished by the shape of the grain, the coarseness and the intended use.

Sofnolime 797

Two grades are available, 797 and CD Grade. The main differences between the two grades are particle size and shape. CD grade is a 2.0mm to 5.0mm extrudate with a D-shaped cross-section. The 797 Grade has a smaller particle size (1,0 to 2,5mm) and has a triangular shaped cross-section, which combine to give a higher CO2 absorption capacity copared with CD grade..

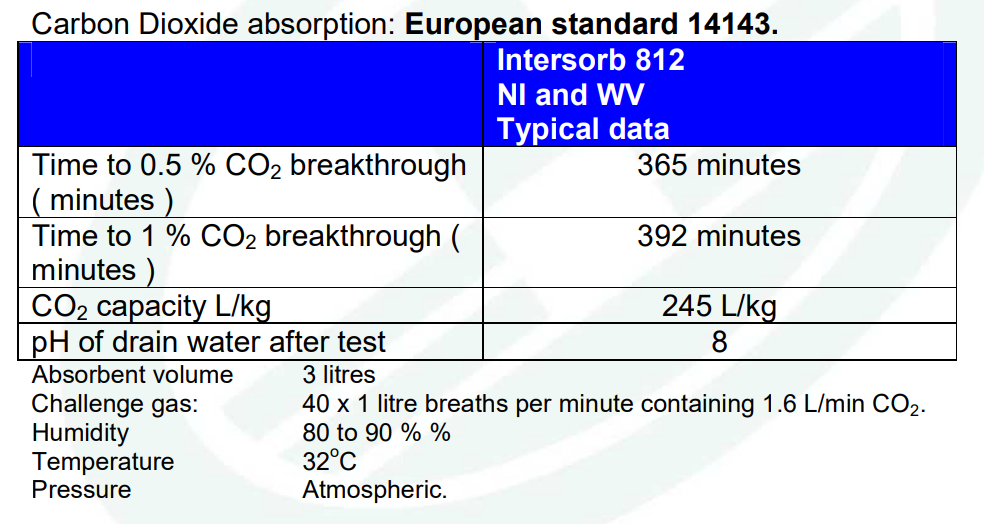

Intersurgical Intersorb 812

Product names: Intersorb 812 NI (non-indicating) Intersorb 812 WV (indicating)

Spherasorb

Website: https://uk.intersurgical.com/products/anaesthesia/intersorb-plus-soda-lime-for-medical-use

Sodasorb by W.R. Grace

MESH SIZE The mesh size most commonly used in rebreathing systems is 4-8 Tyler, 4-88 USS. A finer 6-12 Tyler (USS) mesh material is available for special uses.

Drägersorb 400

Pre-packed scrubber cartridges

Introduction: Scrubbers in closed-circuit rebreather systems remove carbon dioxide (CO2) from the exhaled gas. In an attempt to be more user-friendly and efficient, the non-granular, pre-formed scrubber cartridge has been developed. The cartridge manufacturer (branche known by author) claims twice the absorptive capacity of granular CO2 absorbent, with less variability, lower work of breathing, and reduced exposure to caustic chemicals after a flood. To our knowledge there are no published data that support these claims.

Methods: Cartridge and granular scrubbers of equal volume and mass were tested five times in an immersed and mechanically ventilated O2ptima rebreather. Exercise protocols involving staged (90 minutes 6 MET, followed by 2 MET) and continuous (6 MET) activity were simulated. We compared: duration until breakthrough, and variability in duration, to endpoints of 1.0 kPa and 0.5 kPa inspired partial pressure of CO2; inspiratory-expiratory pressure difference in the breathing loop; and pH of eluted water after a 5 minute flood.

Results: Mean difference in scrubber endurance was 0-20% in favour of the pre-packed cartridge, depending on exercise protocol and chosen CO2 endpoint. There were no meaningful differences in endpoint variability, inspiratory-expiratory pressure in the loop, or pH in the eluted water after a flood.

Conclusions: Cartridge and granular scrubbers were very similar in duration, variability, ventilation pressures, and causticity after a flood. Our findings were not consistent with claims of substantial superiority for the pre-packed cartridge.

Source: https://pubmed.ncbi.nlm.nih.gov/31828749/

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!