An important lesson by Kevin Gurr 2010

LSS Fundamentals

by Kevin Gurr

16-12-2010

It has become increasing apparent in recent years that there is a lot of misinformation with regard to the fundamental principles which govern safe rebreather operations. This is partly due to a lack of precise information from manufacturers and partly due to misuse and abuse by divers in general.

Fundamentals

In order to understand what makes a safe rebreather, firstly one must understand the fundamental properties that govern a rebreather design. This can be divided into 4 areas.

- The resistive work of breathing (WOB) within the rebreather, otherwise known as resistive effort

- The hydrostatic WOB of the unit when submerged

- The absorbent duration

- The oxygen control dynamics.

Looking at each in turn.

The Resistive Work of Breathing-Resistive Effort

This is purely a result of the gas flow restrictions within the unit. In other words how much the size of the pipes and orifices generate a resistance to breathing. Such things as small mouthpiece mushroom valves, small hoses, counter lungs with insufficient volume or room to expand and long absorbent paths within a canister are common elements which go to make up a resistive breathing circuit.

Resistive WOB is also a function of gas density and hence depth. The deeper the dive and the higher the gas density, the greater the WOB. WOB is also a function of ventilation or breathing rate. The more gas flow (higher breathing rate) the more resistance is generated. A rebreather that breaths ‘OK’ on the surface may well not at 40m on an air diluent. Counterlung position and shape also affect the peak pressures experienced in a breathing circuit. This is why current European Standards (EN) and military test standards insist on a resistive WOB measurement at depth and with different ventilation rates and in at least two orientations (swimming positions).

WOB is also subdivided into two areas of concern. The first is a short-term effect (breath by breath) and the second, long term (over a dive). The rebreathers pressure/volume (PV) diagram is normally like a sideways ellipse, as you breathe out it starts from the bottom left and moves to the top right. The reverse is true on inhale. If the ellipse is thin (narrow in the middle) then the energy (joules/litre) consumed within the breathing cycle may be small and the long term energy expended also small, however the higher the angle of the ellipse from the horizontal and there will be a restrictive feeling at the end each breath. This can produce very laboured breathing and a poor short term ‘feel’ to the rebreather. This is a function of the unit’s design in a specific area.

This is the result of the resistive WOB and the effects of the position of the counter lungs about the body when the rebreather and diver are submerged in water. For example, a back mounted counter lung rebreather may have a good resistive WOB but when in a horizontal (face down) swimming position the distance, hence pressure difference between the counter lungs and the lung centroid, may (when combined with the resistive WOB) create an excessive pressure which the diver has to suck against in order to take a breath. In this case the inhale pressure would be excessive (because the diver is inhaling gas from a lower pressure) and the exhale would be easy having breathed out into a lower pressure.

Chest mounted counter lungs have the reverse affect in the same swim position.

It would seem that a perfect solution is an over-shoulder counter lung upon which any hydrostatic effects have little result. However if a rebreather has a poor resistive WOB anyway, the combination of this and any minimal hydrostatic WOB can still mean the unit has a highly restive breathing circuit and hence has a laboured breathing ‘feel’. Long over-shoulder counterlungs may also give poor hydrostatics.

In summary a rebreathers WOB can only be quantified under a range of hydrostatic (rotating) positions with additional measurements at depth. Furthermore, assessing a unit under a range of surface conditions at undefined ventilation rates is inadequate as it is only under stressful conditions (and normally at depth) that we generate high work-rates and this is precisely when the rebreather needs to have a low WOB.

This is a greatly misunderstood area. Many manufacturers quote durations based on simple surface trials which is insufficient and potential dangerous. Absorbent life is primarily affected by the following;

- Amount (Kg or Lbs) of material

- Type of absorbent material, it’s granule size and shape (which in turn affects the WOB) and it’s grade or usage type.

- Water temperature

- The absorbent canisters ability to insulate against the water temperature

- The amount of CO2 generated by the diver

- The gas density/depth

- The style and design of canister

The standard CE test for a canister is done at 40m with oxygen in nitrogen gas mixtures and at 100m with a helium based gas as diluents, in 4 degrees centigrade water temperature at a CO2 generation rate of 1.6 l/min and a ventilation rate of 40l/min. Some navies test canister at around 18m and with as low as 0.5l/min CO2 generation. The CO2 breakthrough figure is referenced to 5mb (ref EN14143).

The range of depths, gas densities, CO2 rates and water temperatures used in each case can, dependant on the canister design, give markedly different durations. What is certain from the data available is that canister durations measured at the surface are dangerously inaccurate for predicting overall dive durations. It can be easily shown that for most axial and even radial canisters the efficiency of the canister decreases significantly with depth. One canister measured went from 77% efficient in 15m to 49% efficient in 40m. The 15m duration was 3 hours while the 40m duration was 1 hour and 50 minutes.

The ‘saving grace’ of currently available designs is that most people cannot maintain rates of 1.6 l/min CO2 or seldom dive in 4-degree water. However data suggests that as a method of specifying canister duration, a single hourly rate independent of primarily depth and gas density, is insufficient and a range of diving parameter curves may be better employed to specify a unit’s duration. In other words in order to assess a rebreather’s suitability for one type of diving over another, it would seem appropriate to test a unit at a range of depths with at least air and trimix/heliox as gases. To provide a safety margin, water temperature and CO2 generation rate should remain constant.

This can be a mechanical or an electronically controlled device. Which ever is chosen it is important that the control of the oxygen level is maintained within certain limits. If decompression is to be conducted using tables or a fixed PO2 dive computer, the limits must be accurately maintained. Rapid excursions to and from depth must also not generate excessively low or high PO2’s. Ideally any such limits reached should generate an alarm, as it cannot be relied upon that the diver will notice especially in a multi-tasking situation. Some rebreather designs, due to high flow rates within the oxygen circuit, can generate massive PO2 spikes sufficient to cause convulsions in a short space of time if left unchecked, this is an undesirable design feature should an addition valve fail. Within the CE and most Navy tests is a PO2 tracking control test as well as an upper and lower limit test after rapid depth changes. With units employing a constant minimum feed of oxygen, which is supplemented by the diver, this minimum should not generate the upper or lower test limits specified.

In addition to and as a result of the above there is the issue of ‘diver abuse’, in particular with canister duration rules. This mainly occurs because of a lack of understanding and information. Common myths seem to be;

- ‘If I use all my canister duration I can just scrape the top off the absorbent and add a bit and get more time’.

- ‘When I have used up all the time on the absorbent I can just dry it out and use it again’.

- ‘As long as I fill a canister and seal it I can use the absorbent anytime in the future’.

- ‘If I partly use a canister I can seal it and use the rest at anytime and get the same duration’.

- ‘If I fully use a canister I can leave it 24 hours to recover and then get more time’.

- ‘I can use my canister at any depth and get the same duration’.

- ‘I can use my rebreather with any gas and get the same duration’.

- ‘I can use my canister in any water temperature and get the same duration’.

- ‘If I run out of absorbent time underwater I will get a small headache and have time to deal with it’.

All of these assumptions have problems in varying degrees of severity. The bottom line is that while the sport of rebreather diving is increasing, unless the education curve follows it, there will be more incidents, most of them avoidable and some of them lethal.

Rebreathers are life support equipment and as such should be tested and manufactured to a standard. In Europe such a standard exists (EN14143). This standard details many tests from work of breathing (WOB), through CO2 canister duration to user interaction and use.

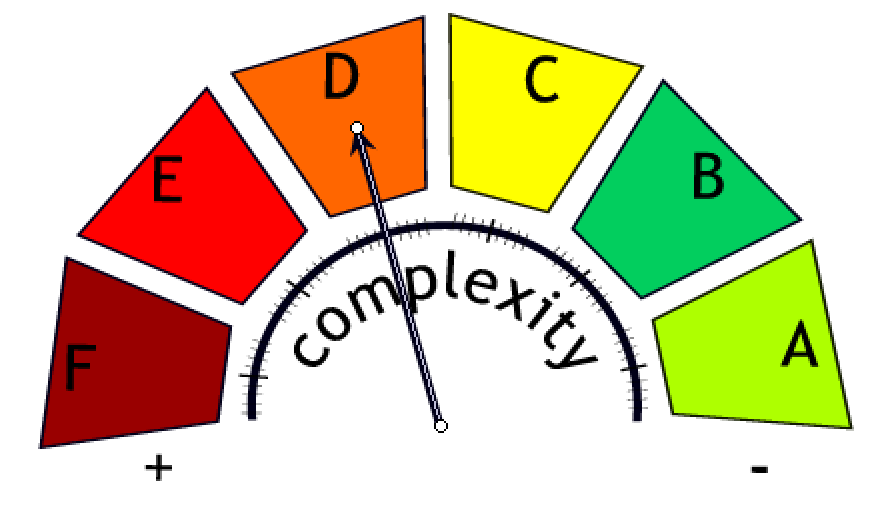

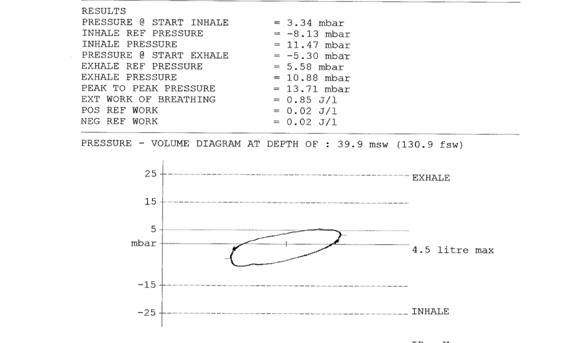

When purchasing a rebreather it is wise to ask the manufacturer for any test data or to which standard it has been tested. A fundamental test is WOB (see graph below). WOB tests the effort needed to breath from the rebreather, it is a measure of the resistive breathing circuit i.e. the sum of all the resistance to gas flow in the circuit.

The graph below shows the peak to peak pressure experienced by the lungs (top of the loop to the bottom), this is the short term ‘feel’ of the circuit. Small peaks and troughs at each end are the effect of the opening of the mushroom valves. The area inside the loop is measured in joules/litre and while having a short term effect, produces the longer term feel of the system. i.e. Just how exhausted you get after a period of use.

The lines at +/- 25mb are the limits at which the human body can easily function for a period.

This test is conducted at a range of flow rates, depths and gas densities.

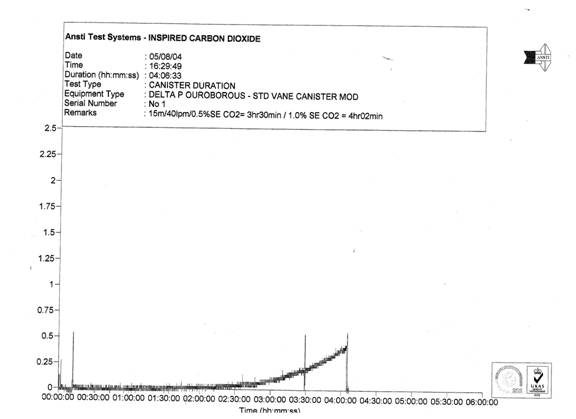

Another important test is the CO2 canister duration. Two critical points are highlighted 0.5% Kpa and 1% Kpa. This is equivalent to 5mb and 10mb of CO2 at depth. 0.5% is seen as the time limit to which the rebreather should be specified. The 1% figure is seen as the safety limit and can range from as little as 10 minutes past the 0.5% limit to over an hour dependant on canister design.

As already mentioned this is massively affected by depth, cold, gas density and CO2 generation rate.

Again when purchasing a unit is it vital you understand the units tested duration with all the mentioned variables.

Gaseous CO2 detection systems are now available (Ref. Sentinel, Rebreather VR Technology). While thermal monitoring has some uses, its’ information can be mis-leading under certain circumstances and is not a finite indication of breakthrough or time remaining.

Laboratory CO2 detection equipment relies on the fact that CO2 (and other gases) absorb a part of the infra red light spectrum. Filament bulbs, detectors and filters are used to measure the amount of light absorbed and hence the CO2 level. In rebreathers, several problems exist. The first is that water vapour reacts in a similar spectrum to CO2. This can give very false readings as the gas cannot be dried successfully. Also oxygen must be considered, especially if the bulb breaks! Signal noise, power supplies and a host of other problems make the implementation of gaseous CO2 systems difficult for manufacturers. If you do not have CO2 monitoring then be respectful of your canister and do not abuse the time limits.

Some manufacturers realise that packing errors have been an issue with absorbent and are designing pre-packed cartridge systems both in granules and ‘solid’ fill options.

In recent years there has arrived an alternative to granular fill absorbent materials. Micropore in the USA have produced a material wrap based system which is basically impregnated with a version of the granular material but comes as a solid cartridge. This system offers the following advantages;

No user error in packing

Reduced Work of Breathing over granules

The current trade off is cost and possibly a reduction in life over granules, but this should change as more and more systems use it.

It is very simple to make a rebreather that ‘works’. It is not easy to make a unit that performs. By that I mean that as the diver becomes more stressed, the unit needs to have a performance level that aids rather than impedes the divers’ ability to survive. Just having a unit that ‘feels’ OK on a dive may not mean it performs well under stressful conditions. Poorly designed breathing loops, untried canister designs and environmentally untested sub-standard components are a recipe for disaster.

In summary, there are many elements to rebreather testing (not just WOB or canister duration) that are critical to defining whether a unit is suitable for the style of diving and the environmental challenges a user may but it through.

Rebreather Life-Support System (LSS) survival

Read and understand this prior to using any unit. If you do not understand any or all of this section please contact your training agency or supplier as appropriate.

Rules for LSS Diving

- Always do all pre-dive checks.

- Always pre-breathe the canister for at least five minutes with your nose blocked!

- Do not modify the LSS without the manufacturer’s written consent.

- Do not use a full-face mask, which is not designed for a LSS. There is too much CO2 dead-space.

- Always know your PO2.

- Never dive a unit you suspect is leaking.

- Be especially diligent close to and on the surface where the PO2 is potentially lowest.

- Never leave your mouthpiece open on the surface.

- Never use a pure gas in the diluent cylinder. You should have a breathable diluent available for the each section of the dive.

- Take time to adjust your weight correctly, do not dive over-weighted.

- Have two sources of buoyancy and buoyancy inflation.

- Practice a skill on every dive.

- Avoid unnecessary mask clearing.

- Regularly disinfect the unit.

- Never dive a re-packed canister.

- Never hold your breath during an ascent

- Do not dive with a low battery alarm.

- Change all main electronic batteries at the same time.

- Always carry bailout gases of sufficient volume for the planned dive as per your training agency recommendations.

IF IN DOUBT, BAILOUT!

A big thank you to Kevin Gurr for this important lessons!