“Lieutenant Lund“

This fantastic article about the history of the Lt Lund I and Lt Lund II rebreather is written and published by Helmut Knüfermann. It is with great pleasure that I am able to offer the readers of my website this fantastic story thanks to Helmut’s generous offer that I could translate his article into English and display it on my website! Here is part 1 of a journey through time, thanks to Helmut!

Lieutenant Lund a Biography by Helmut Knüfermann

Biography of a creative and resourceful Norwegian naval officer (I)

For many, the “Lieutenant Lund II” diving device was the epitome of a legendary oxygen recycler.

The device was manufactured from 1953 by Dräger-Werke in cooperation with Lieutenant Lund, the first commander of the ” Marinens Froskemannsskole , Horten” in Norway and was used by numerous naval units worldwide until the mid-1960s. Although it was designed exclusively for military use, it also found its way to civilian divers here and there. To this day, the “Lieutenant Lund II” is still highly sought after and has lost none of its aura.

But who was “Lieutenant Lund”?

Many extensive and often meticulous investigations have led to the life story of this dedicated military diver in recent years.

First years of life

Bjørn W. Kahrs [1], who has worked extensively on Lund’s biography, writes:

Ove Lund was born on May 25, 1924 in Oslo. His father, Sverre Lund (1888-1942), was married to Augusta Rebekka Rosenvinge Kolderup (1892-1987). She was a dancer in the “Chat Noir ” cabaret theater in Oslo (still exists). Together they had two sons. His older brother died at the age of nine in 1927.

Ove Lund’s father was the manager of a sports and hunting goods store in Oslo called

” Ludvig Torgersen & Co. A/S”. This company has been run by the Torgersen family since the turn of the century . Father Sverre Lund died in 1942 at the age of 54.

In early 1943, Ove Lund completed his schooling with the “Examen artium ” in Physics, Mathematics, Chemistry and Latin at the ” Fagerborg School” in Engelsklinjen , Norway. At the same time, he successfully completed training at a trade school. In the same year he enrolled at the University of Oslo. His future wife “Randi” went to the same university and studied the same subjects in the same year as him.

The time under German occupation

Norway was occupied by Germany at the time. On November 30, 1943, the Wehrmacht closed the University of Oslo, arrested about 1250 students and sent them to a camp in Norway. About 350 students were deported to Germany in January 1944 for a (fruitless) re-education in the ” QuislingsPartei ” ideology at Sennheim SS training camp near Strasbourg and to the Buchenwald concentration camp . All other students were released by the Wehrmacht a little later . One of them may have been Ove Lund. It is also possible that he was not near the university during the arrests. Military records indicate that he was a member of the Norwegian resistance (“Mil.Org.” http://mil.org) against the German occupation from 1943 to 1944.

He apparently fled to Sweden, because there he was registered on May 24, 1944 with registration number 26807 in the ” Kjæseter ” [3].

From May 1944 to August 1944 he trained as a police soldier in Sweden, a Norwegian force that would enter Norway and serve as a police officer after the German occupation.

However, according to military records, Lund began training as a military pilot in Norway in August 1944. As early as November 1945 he was a pilot with the

“Royal Norwegian Air Force (RNAF).

Leave after the war

Return to Oslo. In 1945 Ove Lund started working for

Ludvig _ Torgersen & Co. A/S” in Oslo, initially as a property guard, and in 1946, at the age of 22, he became manager of this company (Photo 1), where his father had already worked in the same position.

From 19 May 1949 he lived at 23 Holmendammenterrasse in Oslo- Smestad and married Randi Margrethe on the same day Bentzen .

Randi Bentzen completed her education at the “Otto Treider School of Commerce” in Oslo after the closure of the University of Oslo in 1943 until the end of the war. When she married in 1949, she had already been a secretary for the insurance company Storebrand for four years.

Photo 1: Ove Lund, general manager at Ludvig Torgersen & Co. A/S / Source: Bjorn kahrs

As a manager of the sporting and hunting equipment store ” Torgersen & Co. A/S” in Oslo, Lund, as an avid recreational diver, had a large number of their own sales range of diving equipment at his disposal. Together with his cousin Ragnvald Koldrup , who was also an avid diver, they probably made extensive use of this opportunity.

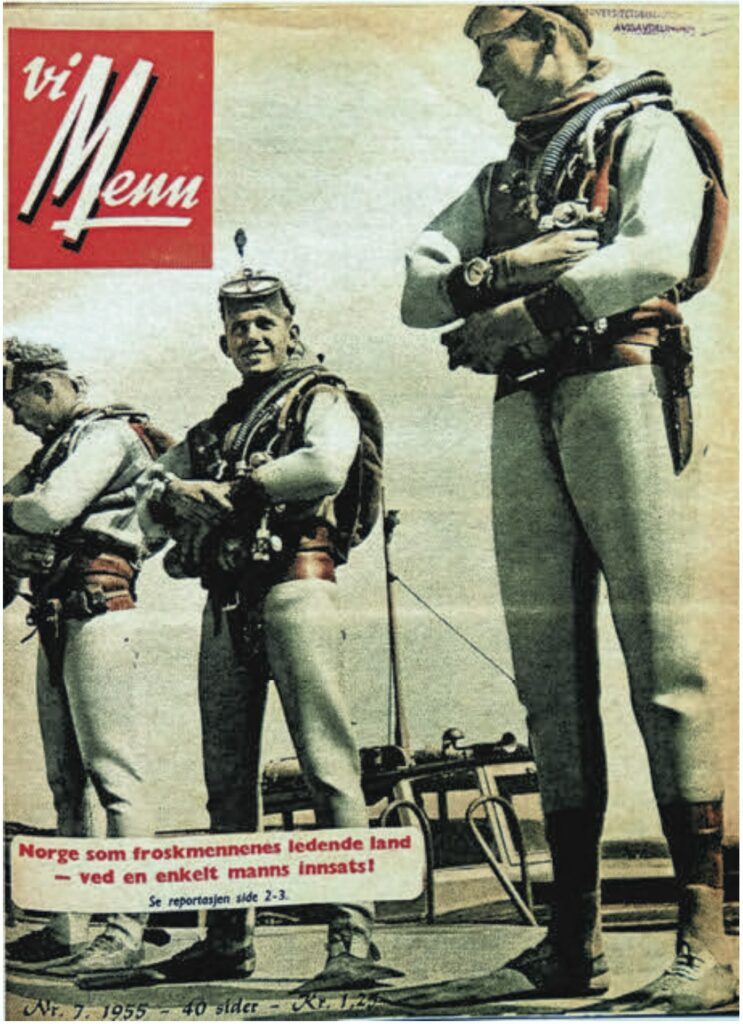

Oslo’s ” Torggata Bath” in the early 1950s . In the magazine ” Vi Menn ” from 1952, number 7, Lund himself describes a funny training incident from the spring of 1951: “To be as inconspicuous as possible in the Torggata pool, we put on our diving suits in the changing room and quickly entered the pool. But instead of diving, we floated on the surface. We forgot the weights”. So instead of less attention, there was a lot of attention. The laughter of the swimmers must have been great.

Although they made many parts of their diving equipment themselves, their aspirations became more professional. They purchased essential pieces of equipment through ” Torgersen & Co”‘s existing business relationships abroad. It is no longer possible to determine what diving equipment they used. Presumably, however, Lund and Koldrup had at least one example of the “Dräger Kleine Dive-Dräger 138″, with which they then moved to the more modern Oslo ” Bislet Bad”, where they subsequently attracted truly extraordinary attention.

Enthusiastic recreational divers, professional amateurs

In the early 1950s, the Norwegian “SOK E-Service” of the ” Sjøforvarets Over Kommando ” (Navy High Command) started planning a Norwegian Marine Frog School. It was the successes of the Italian and British underwater saboteurs in World War II that kept the people of the E-Service busy.

In the autumn of 1951, the Commander-in-Chief of the Navy, Commander Captain Johan Greve Brun , was visited in his office by Captain Andreas Stang of the E-service, who reported on two enthusiastic recreational divers who were undergoing professional diving training in the swimming pool of the ” Bislet -Bad” in Oslo.

Stang asked the commander if he would be interested in a visit to show what he thought was important for the navy. Greve Brun gladly agreed to consider this military discipline, which was new to him. Captain Stang hoped that this would have a positive influence on the establishment of a frog school.

Lund and Koldrup presented their demonstrations of silent and bubble-free diving tactics to the Navy captains. The results of these demonstrations must have been viewed very positively. The foundations for the plans to establish a marine frog school were laid. However, when the plans had to be put into practice, it became clear that the Navy would not be able to fund the equipment needed to start the frog school.

Captain Stang, whose decision-making powers were limited, then contacted E Service Chief of Defense Wilhelm Evang and presented the Navy’s plans to recruit the first frogmen.

This “intelligence manager” had a bright idea and as a result he got the “Norsk Etterretningstjeneste ” (Norwegian Intelligence Service) to finance the purchase of equipment on a reasonable scale. The training of the first frogmen could therefore begin quickly.

When Wilhelm Evang suggested that Ove Lund lead the newly founded school, Lund gratefully accepted the leadership position.

According to military records, Ove Lund must have joined the Norwegian Defence Service in 1952, as he received a special service order from July 1952 to May 3, 1953 for frogman training at the “SOK/A III E” (Navy Command in the USA).

According to Erling Krange [7] Ove Lund was appointed first lieutenant (which would have been unusual even by the military rules of the Norwegian Navy) to be trained and gain experience abroad, especially in the United States, but also in England.

In the fall of 1952, he voluntarily participated in rigorous training by UDT II (UNDERWATER DEMOLITION TEAM TWO, Atlantic Fleet ), a US Navy special forces unit in the US (photos 2 and 3). He received training with the “Dräger Kleintauchgerät 138”, which used the UDT in the Korean War (1950-1953) alongside other oxygen rebreathers . His wife Randi accompanied him to both the US and England for training.

Photo 2: “After the course at Underwater Demolition II in the US, Ove Lund received a nice paddle with inscription from Ltn . Commander Saunders and Cain” / Photo: Vi Menn, Left: Lieutenant Lund / Source: Bjørn Kahrs

Photo 3: Lieutenant Lund, (5th officer from left) US-Navy UDT II, ( underwater demolition team two ) / Source: UDTR II, Class photo

In December 1952 (during his Christmas holiday at home) Lund met Heinrich Dräger at the Drägerwerke in Lübeck [4]. In his luggage was the concept of the “SOK E-Service” for the planning of a “Norwegian Navy Frog School”.

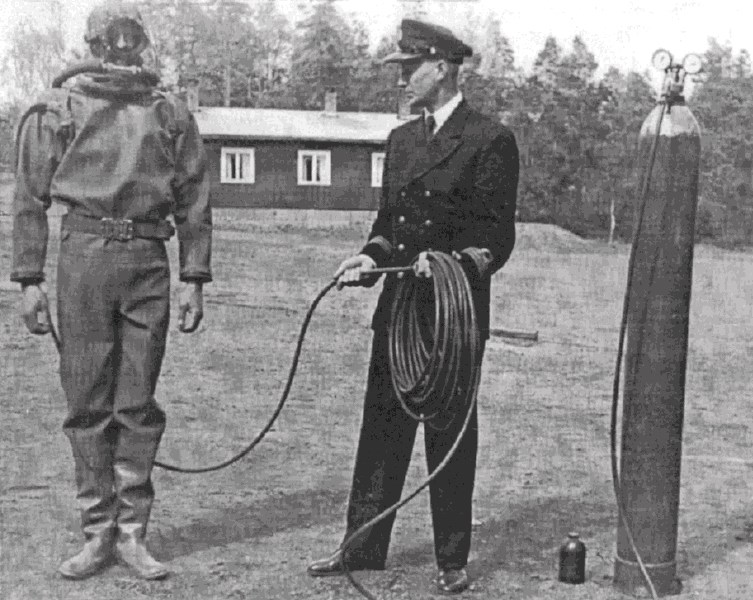

The Norwegian Navy authorized Lund to purchase the necessary equipment. Due to his fresh experience with the Dräger Rebreather in the US Navy, the choice for a “Dräger “Oxygen small diving apparatus” (Kleintauchgerät 138) (Photo 4) was obvious. Initially, an agreement was reached on an initial delivery of a few units. There is no data on the exact number of units.

On the occasion of this visit, he also negotiated a contract for the sale of Dräger compressed air equipment and Dräger Kleintauchgeräte and accessories to the US and Canada [4]. The contract was drawn up in the name and on behalf of the company ” Ludvig Torgersen & Company” in Oslo and was signed on 12.12.1952 by “Herrn Ingenieur Lund” and “Heinrich Draeger”. A sales commission of 5% was negotiated. The contract was valid until 31.12.1954. It is unknown whether and to what extent sales to the USA and Canada were subsequently made on the basis of this contract At this meeting, the possibility of marketing the “Dräger swim-diving suit” under the name ” Lieutenant Lund” was also discussed, but no contractual commitment was made in this regard.

He travelled back to Norway with clear plans for the new Frog School. In March 1953 he worked out the projects according to his ideas with the first trainers in Oslo, Ørnulf Theodorsen and other trainers. That same summer, the first test of Norwegian frogmen took place on the Bolærene archipelago in the Oslo Fjord. Eight of the 24 candidates were selected.

The students came from the Navy and the Coastal Artillery. Subsequent courses would include participants from Denmark, the civil fire brigade and the Norwegian police. Lund had the course run according to the hard US UDT model. The candidates were trained over and over again to become perfect saboteurs and underwater hunters. In the time of the “Cold War”, also for Norway as a founding member of NATO since 1949, an indispensable task force.

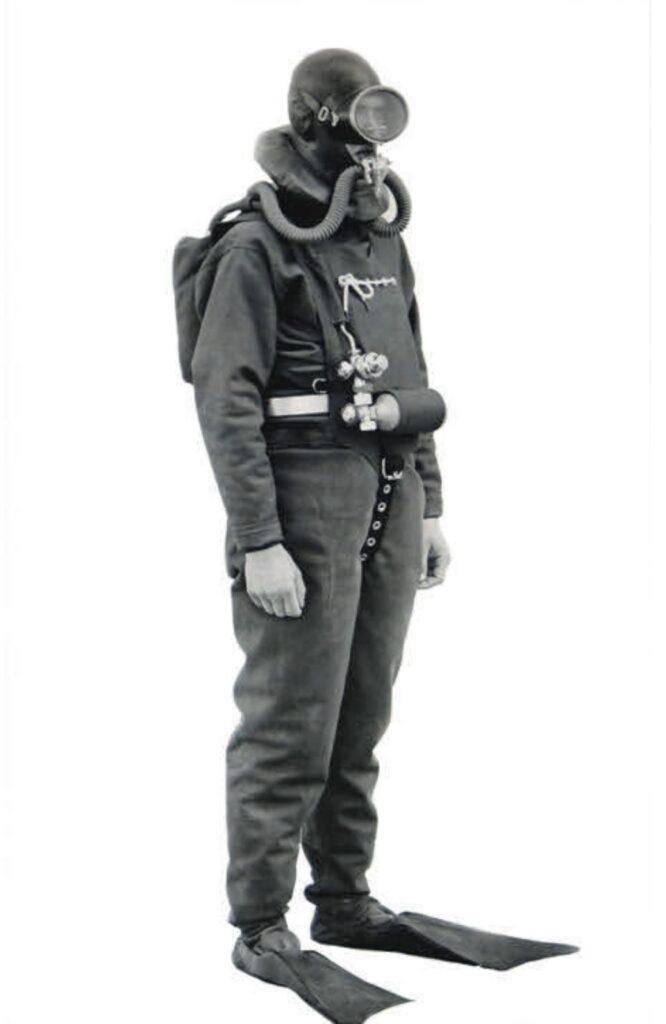

Photo 4: “Dräger Kleintauchgerät 138″ with Dräger swimming diving suit and ” Barakuda ” fins , photo from 1952 / © Dräger Archive , Photo: HK

Initially the school was led by Captain Halvor Schei . However, Lieutenant Lund, permanently in charge of daily training, was the authoritative manager for the entire frog school. That is why he is also listed in the documents as ” Første chief for Marinens Froskemannskole ” (first head…).

For the first two years, the school and training were held on the island of Bolærene in the summer and on Østøya , an island in Horten Municipality in Vestfold in the Oslo Fjord, in the winter. Finally the entire training all year round was moved to the Island Østøya.

In many ways, it was a true pioneering time for the first Frogman School, as this new naval special unit struggled to find its future purpose. Those who started this school were real “professional amateurs” who had no basis of comparison in Norway other than the ” Kongelige Norwegian Marines Froskemannsskole “. It was the first of its kind in Scandinavia.

Equipped with the first oxygen rebreathers, model

Dräger Kleintauchgerät 138.

Dräger-Werke in Lübeck supplied the Norwegian Navy with some of the first oxygen rebreathers of the “Dräger Kleintauchgerät 138” model 953 (Photos 4 and 5).

This type of device was developed in 1952 as a further development of the swimming diving device designed in 1942 by the chief engineer and technical director of the Drägerwerke Hermann Otto Stelzner and the marine scientist Hans Hass.

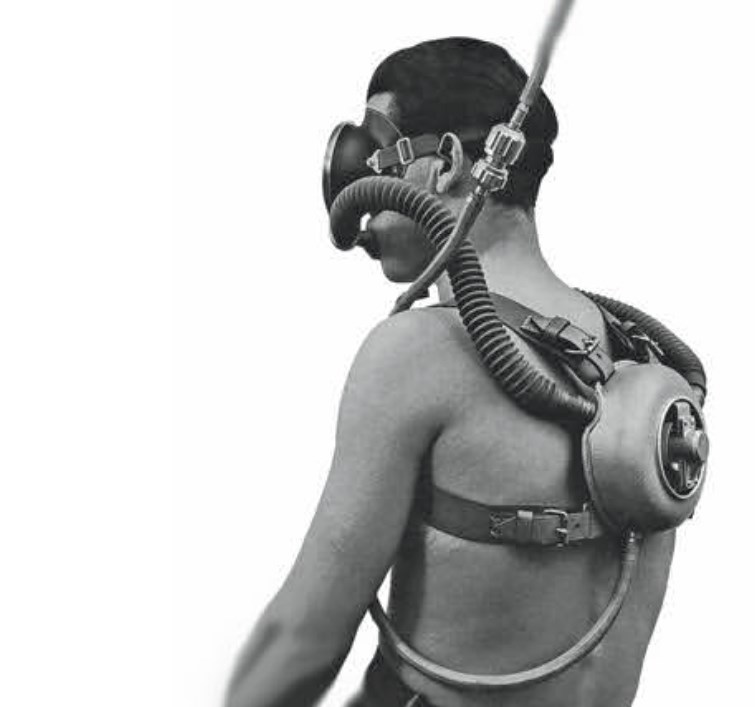

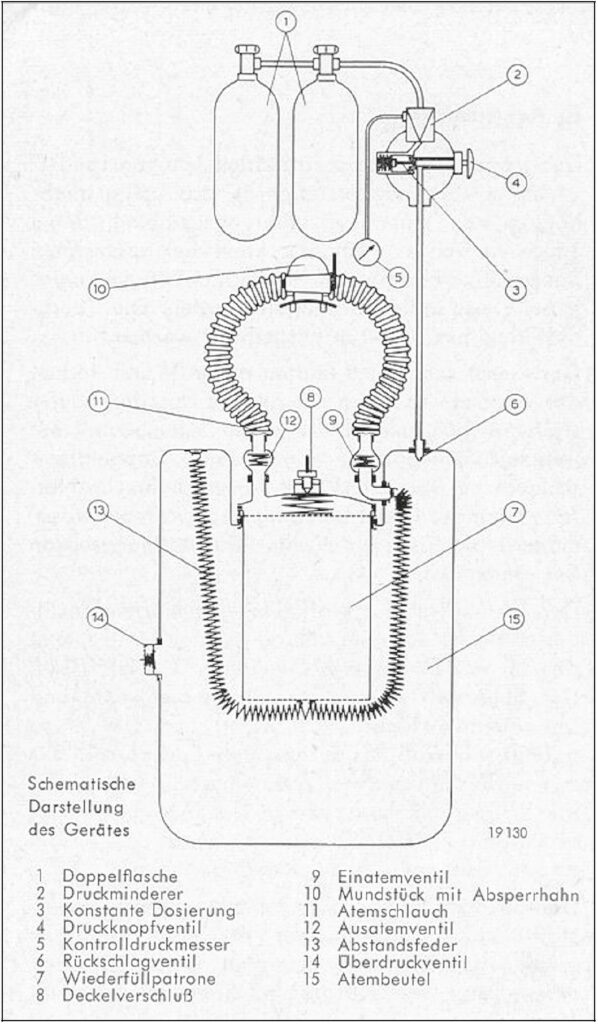

A nearly bubbleless rebreather with a continuous oxygen supply of 0.9 l/min, a pressure regulator with an additional oxygen valve and a pressure relief valve in the breathing lung.

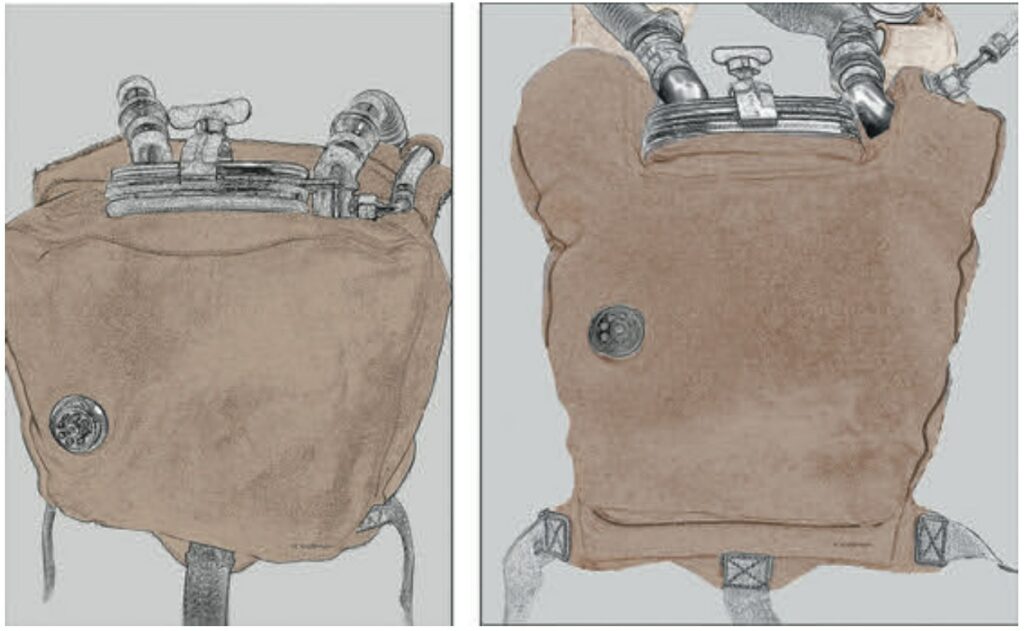

A breathing bag was built into the rear part of the vest, made of reddish-brown textile material with a rubber lining . In the chest area of the vest was an oxygen bottle with a capacity of 0.6 liters and a filling pressure of 150 bar. A breast pocket above the oxygen bottle contained flat weights to compensate for the buoyancy of the device underwater.

Photo 5: “Dräger Kleintauchgerät 138” / © Dräger Archive , Photo: HK

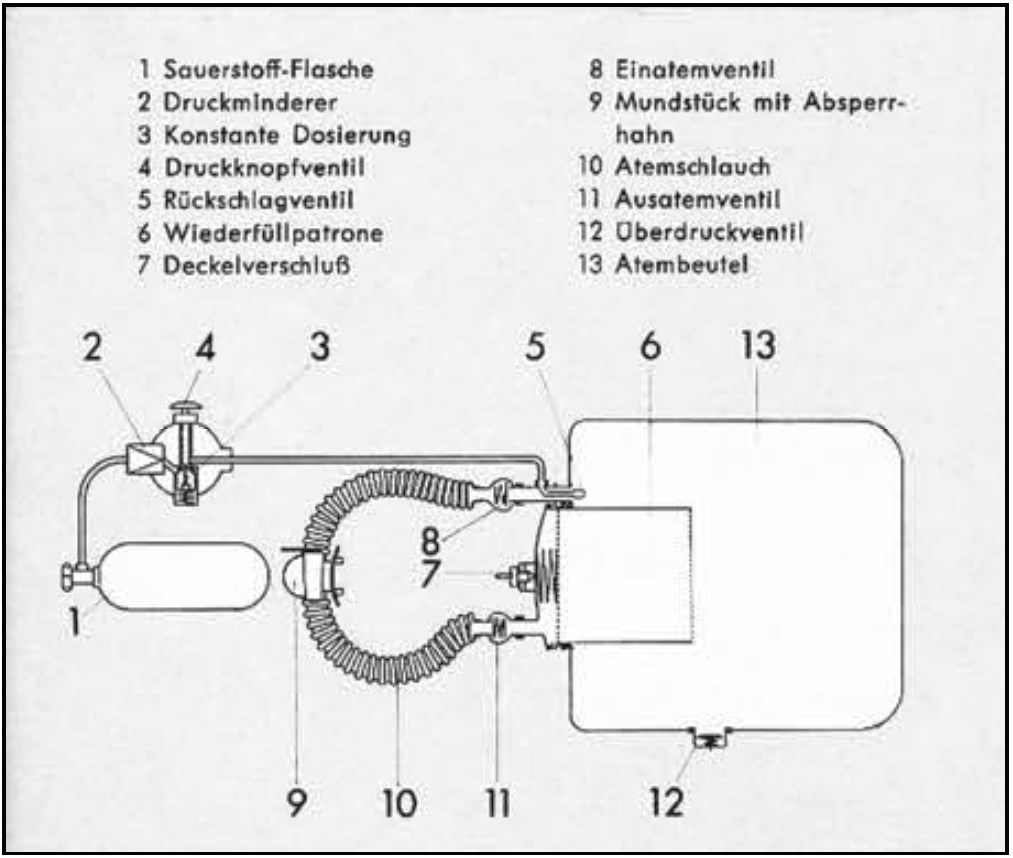

Inhalation and exhalation were performed through separate corrugated hoses. The inhalation and exhalation valves were not located directly on the mouthpiece, but in the hose connections on the scrubber side of the device. In this way, the breathing gas circulated through the refillable cartridge with one liter of soda lime and the breathing lung with a capacity of approximately 7.5 liters (Schedule 6).

Schedule 6: The “Dräger Kleintauchgerät 138”, schematic representation from the Dräger brochure of January 1961.

The metal nozzle could be closed by means of a shut-off valve (Photo 7) to maintain a closed circuit during extraction, both above and below water. An eye on the mouthpiece kept the nose clip on the strap, the use of which was mandatory at that time. The weight of the device, complete with counterweight, was about 10 kilograms.

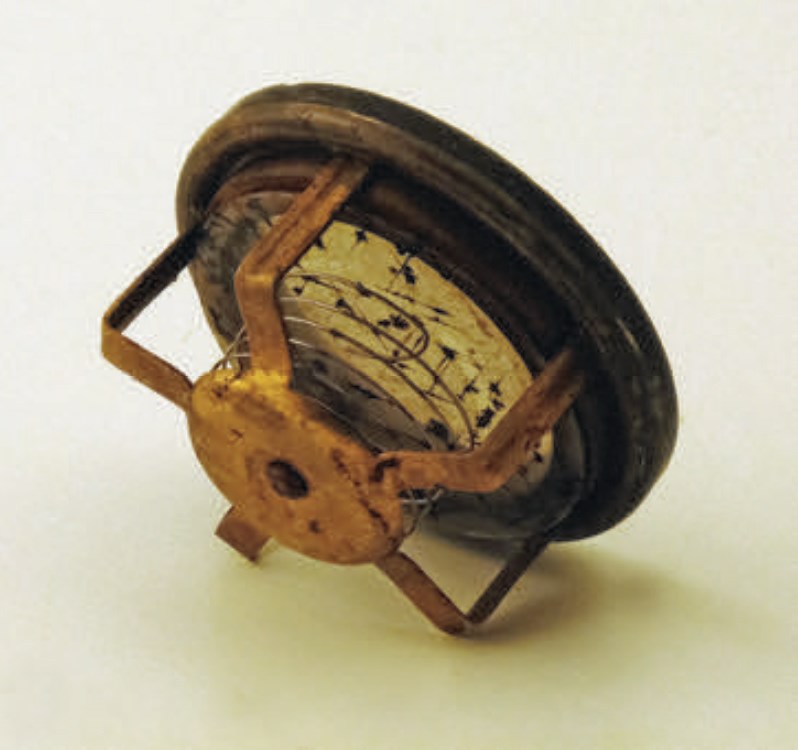

Photo 7: Nozzle with tap of the “Dräger Kleintauchgerät Mod . 138” / © Dräger Archive, Photo: HK

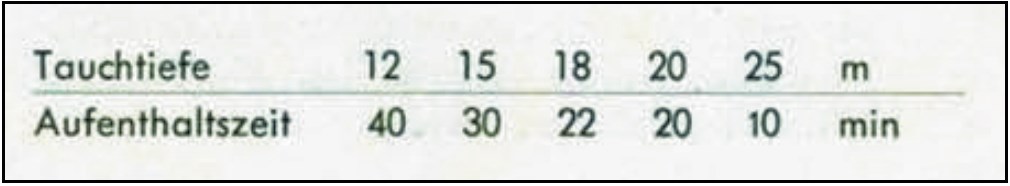

The limit values for depth of use and duration of use in the 1952 Dräger Instruction Manual 65-G 11/G (1st edition) for the “Dräger 138” referred to a “low level of physical work” at approximately 85% oxygen concentration in the breathing bag – after ventilation and fill with pure oxygen as prescribed” (table. 8).

Although the dangers of oxygen deficiency and oxygen toxicity were clearly pointed out in the instructions for use, these usage data seem risky in the light of today’s knowledge. But none other than Hans Hass himself, who is partly responsible for the construction of this circulation device, sometimes dived more than 25 meters deep with it.

Despite the high demands and known risks, Lund trained his frogmen with the utmost care and attention. Operational diving depths were very limited.

Table 8: Original table for the dive duration and depth of the “Kleintauchgerät “Dräger 138

Photo 9: “Dräger Kleintauchgerät Mod.138″ with pressure gauge. Special production for the ” Norske Marines Froskemannsskole ” / © Dräger Archive, Photo: HK

However, the first experiences soon showed that the “Dräger 138” was insufficiently suitable for its intended purpose. A pressure gauge was missing.

The professional manoeuvres of the “Froskemenn” students led to significantly higher oxygen consumption than previously known from the civilian sector. Constant monitoring of the oxygen available during the missions was essential. That is why the Norwegian Frogman School got a special version of the “Dräger 138″ within a short time the Dräger 138” with a “fold-down” pressure gauge (Photo 9).

This pressure gauge was located at the end of a high-pressure hose, connected to the pressure regulator, in a hinged, lockable holder that could therefore be easily folded-open under water and had luminous numerals. This hinged pressure gauge was also used in Dräger compressed air equipment at the time. Or the ones already delivered

“138s” were retrofitted with pressure gauges, or whether new models were produced with pressure gauges, is not documented.

By the fall of 1953 it became apparent that the Frogmen operated with amazing skill and were highly trained. That is why they took part in Norwegian naval exercises for the first time. First in the bigger exercise “MARINER” and later on the smaller exercise called “MARNOR ONE”, which was conducted in the last half of September 1953.

Professional frogmen, first exercises

When the frogmen made their first sabotage attacks on various targets in the Kristiansand region , it was quite noisy at times. This did not go unnoticed by the shocked population.

The local press published startling headlines:

“Frogmen Sighted at Night at Møvik and Flekkerøya “.

“During the war there would be no more oil loading stations in Christiansand “.

” Odderøya and Møvik Taken by Frogmen”.

Odderøya Fortress was overpowered by frogmen and “… “disarmed, gagged and bound …”, as confirmed in the report of the fort’s training officer.

That same night, the frogmen went up the Otra River to the Lund Bridge and fired explosive charges at Elvegata , shattering large windows, while frightened villagers called the police to find out what had happened. The police were on the scene in advance. informed of what would happen during the exercise, so that those who inquired could be somewhat reassured.

The explosions made a lot of noise and smell. It hadn’t been more than eight years since the war and many still had the hellish scenario fresh in their minds.”

The people immediately submitted the report of the extent of the destruction to the head of the naval command . Long interrogations and meetings followed, with the result that damages were paid and future exercises would be conducted without live ammunition.

But even without real ammunition, the frogmen continued to demonstrate their skills. The subsequent articles in the newspapers speak for themselves:

“In late January, the ammunition depot watch commander and later the rest of the watch were overpowered by a total of 15 frogmen”.

Thus, a whole series of other “tactical exercises” are sufficiently documented. In contrast to the strict secrecy of combat swimming operations today, underwater military operations at the time were sensational and, under the leadership of Lieutenant Lund, also an attraction, in which the population took a keen interest and were described accordingly by the press. Lieutenant Ove Lund was prominently featured.

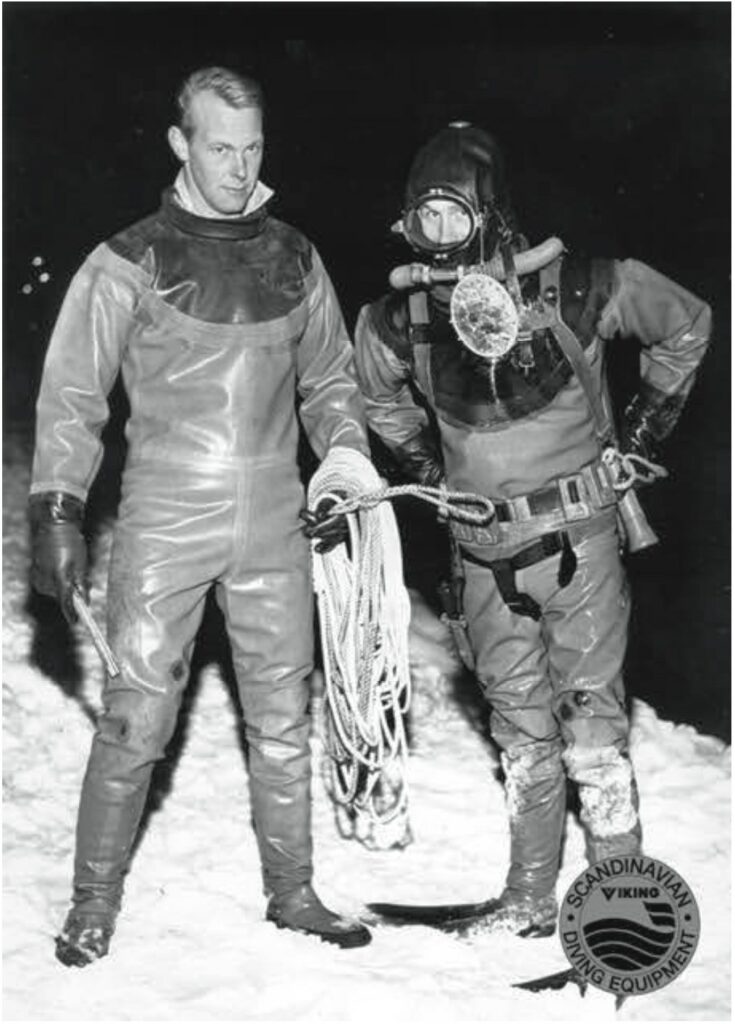

Lieutenant Lund, designer of the first “Viking” dry suit

The equipment for the divers at the Frogman School at that time left much to be desired. The first sponge rubber wet suits were not suitable for longer missions in Scandinavia.

In 1952 Lieutenant Lund made the first contacts with a small rubber factory in Stavanger called ” Vestlandske Gummivarefabrikk A/S” and brought designs for the production of a rubber dry suit . Together with the head of development there, Bernhard Olsen , who produced the first prototype, the first (green) natural rubber suits were produced within a short time (Photo 10).

In 1953, Lieutenant Lund received the first two-piece version of these suits (still with a waistband closure). They had no zippers or valves. The suit was inflated with air from the mask through the hood. During ascent, the air was released through the cuffs.

Photo 10: First “Viking” drysuit , (“green”), designed by Lieutenant Lund in 1952 / Photo: magazine ” Vi Men “.” Vi Menn “, Source: Bjørn W. Kahrs

The Norwegian Navy ordered a similar number of these packs at a price of NOK 376/piece (Photo 11).

Initially they were not used below a depth of 10 meters. It was only later that the suits were equipped with an automatic drain valve, which somewhat facilitated their use.

The Vestlandske Gummivarefabrikk A/S” became the company “Viking Stavanger A/S” in the 1960s , which has successfully made a name for itself worldwide (under the name ANSELL) with the production of professional Viking diving suits. [5]

The oxygen diver “Lieutenant Lund I”

(“Dräger Kleintauchgerät model 138L”)

It was foreseeable that the missions with the initially used “Dräger small diving device model 138″ would not be satisfactory for military operations in the long term. So there were new developments. In late 1953, Lieutenant Lund, together with Chief Engineer Hermann Tietze , designed an improved oxygen rebreather to his specifications at the Dräger factory in Lübeck. The most important requirement was: a longer useful life. It was named ” Lieutenant Lund I” in the course of further use.

The description follows below, as the “Lieutenant Lund I” was the model for the “Lieutenant Lund II” rebreather described below and the later versions “NORGE I + II”.

“NORGE I + II” and the “Model 600”.

Photo 11: First “Viking” drysuit , designed in 1952 by Lieutenant Lund, ” Første chief for Marinens Froskemannskole ” / Photo: VIKING-ANSELL, (History)

Photo 12: Dräger Kleintauchgerät “Lieutenant Lund I” (Dräger 138 L) / © Dräger Archive, Photo: HK

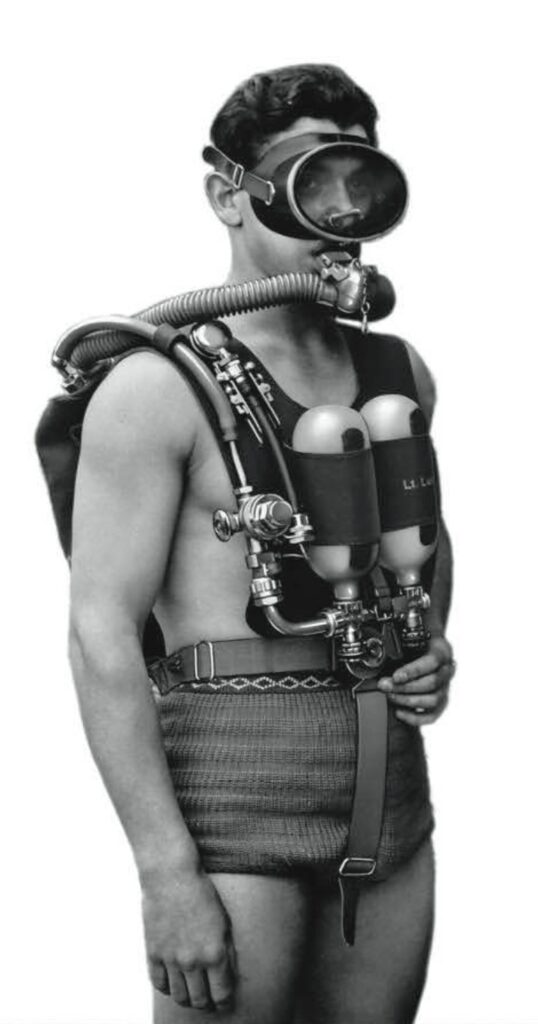

The “Lieutenant Lund I” was a device of the same design as the “Dräger 138 Kleintauchgerät”, but with two oxygen cylinders of 0.8 liters each placed horizontally on top of each other on the chest, instead of the previous one cylinder of 0,6 litres. With an increased filling pressure of 200 bar, the diver now had 320 liters of oxygen at his disposal instead of the previous 90 litres. Since it is not primarily the supply of breathing gas that limits the life of oxygen rebreathers , but the quantity and CO2 absorption capacity of the scrubber, the scrubber tank also received a larger filling volume, from one to two litres. The maximum dive time was now about 90 minutes, with an average oxygen consumption of up to 2 l/min easily achieved.

The position of the oval lime container in the breathing bag itself had the advantage – as with almost all oxygen rebreathers in “Western” design – that the soda lime retained a good CO2 binding capacity in the ambient heat of the exhaled air, even at low water temperatures. In latest generation hard-shell units, in which the scrubber tank is installed separately and directly surrounded by ambient water, separate insulation helps to prevent cooling, which can shorten the life of the scrubber by more than half at temperatures around 4°C and lower.

Because pure oxygen was used as the breathing gas , the working depth – as with all closed breathing apparatus without exception – was theoretically limited to about six meters due to the oxygen toxicity at a pO2 of 1.6 bar, but in practice (due to a never-present one hundred percent O2 concentration in the breathing bag) up to ten metres.

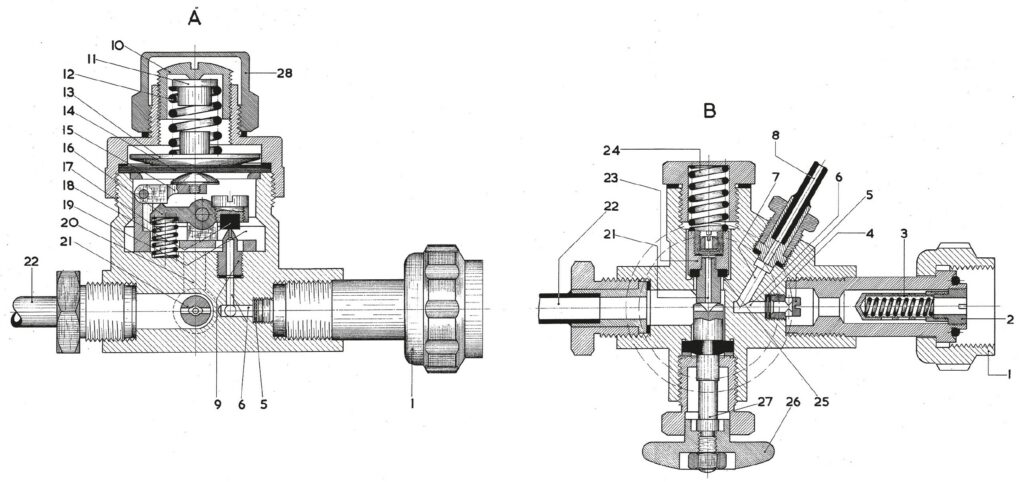

The pressure regulator (Photo13 and drawings 14 A/B), of the same design as that for the “Dräger 138”, also provided a constant dosage set at 0.9 litre/min, which could also be directly increased by an increased oxygen inflow through the integrated manual bypass valve. Drägerwerke adopted this pressure regulator in the same and modified form for later diving devices in the “Lund-Westen” design.

The schematic drawing and functional description therefore apply to all these devices.

Function of the pressure regulator of the Dräger ” Lieutenant Lund I

Photo 13: Dräger pressure regulator, drawing no. “T 5800” / © Photo: HK

Drawing 14A shows a vertical section through the pressure regulator and Drawing 14B shows a horizontal section through the dosing nozzle with the “manual bypass valve”.

Drawings 14 A and B: Schematic drawing of the pressure regulator of the Dräger oxygen rebreathers “Kleintauchgerät 138”, “Lieutenant Lund I + II”, NORGE I + II” and “Modell 600″ / © drawing from: ” Beskrivelse af svømmedykker – material . Udarbejdet af P. Jarlskov , April 1957″.

Functional description

The pressure regulator is connected to the oxygen bottle with a G3/4″ union nut

(1) A mouthpiece

(2) contains and centers a very fine rod filter

(3) Through this passage to the next nozzle

(4) the oxygen passes through a 3-layer membrane

(5) that retains the smallest impurities to the channel

(6) From here leads a branch channel

(7) to the pressure gauge hose

(8. The channel (6) continues in a perpendicular bore

(9) for setting the medium pressure reducing valve.

The intermediate pressure of the pressure reducing valve can be adjusted by adjusting the sealing ring screw above (18). From there the pressure reaches the pressure plunger (11) at the top with the spring (12), the pressure disc (13) and the diaphragm (14), which controls a continuous oxygen supply of 0.9 l/min and flows through the slot in the union nut ( 10) can be set.

The diaphragm (14) rotates to its rest position via the pressure mushroom (15). The valve (16) causes the regulator (18) to rise and allows the oxygen to flow from the channel (6) into the cavity (19). As soon as the pressure rises to about 4.5 bar, the oxygen pressure on the diaphragm (14) increases, overcomes the back pressure of the spring (12) and the closing spring (17) and can now move the valve (18) to shut off the oxygen supply. to close.

Just like the pressure regulator (with outlet of high-pressure manometer), the mouthpiece with shut-off valve was also adopted from the “Dräger Kleintauchgerät 138”, as were the inhalation and exhalation valves, the pressure relief valve in the breathing lung and the fold-down pressure gauge for checking the tank pressure during the diving.

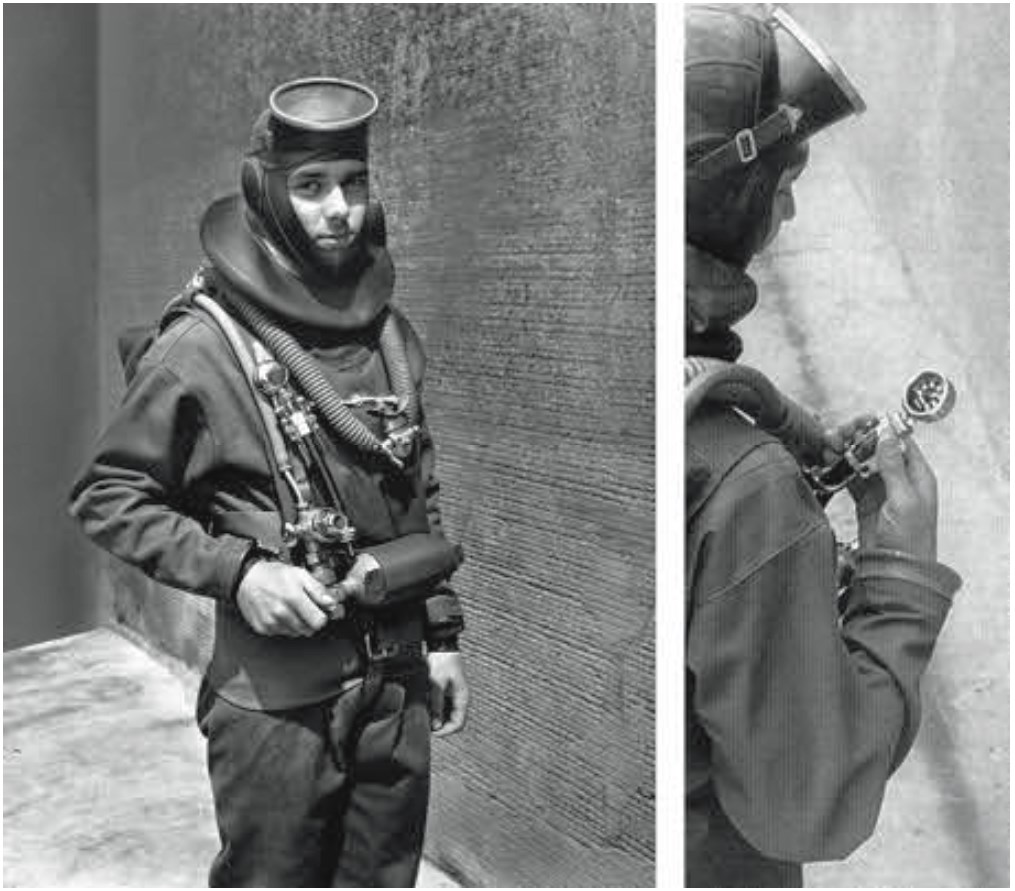

In contrast to the “Dräger 138”, the breathing lung on the back has a modified shape with two bulges on the right and left above the access to the scrubber (Photo 15). The close fit to the body and the favourable shape, especially the bulges in the shoulder area, resulted in excellent breathing resistance ratios in every position and ensured a stabilizing swimming position (Photo 16).

Compared to the “Dräger 138”, this resulted in a slightly larger breathing lung volume of about seven to eight litres. The compensation weight bag was now placed on the side of the breathing lung facing the diver’s back.

For non-use of the device under and above water, there was a simple shut-off valve in the valveless mouthpiece that was connected directly to the inhalation and exhalation tubes (Photo 7).

Photo 15: Comparison of the shapes of counterlungs, left: “Dräger Kleintauchgerät 138”, right: “Lieutenant Lund I + II” In contrast to the “Dräger Kleintauchgerät 138”, the counterlungs of the rebreathers “Lieutenant Lund I and II” were given a new shape with two bulges left and right above the access to the lime reservoir / Graphics: © HK

Photo 18: The precision compression spring made of stainless spring steel wire to press the valve disc / Photo: © HK

Photo 16: The close location on the body and the favorable Shape, especially the bulges on the Shoulders, excellent in every position

provide low Breathing resistance ratios and ensured a stabilizing swimming position / © Dräger Archive, photo: HK

Photo 17: The open breathing tube connection on the side of the unit with the mica valve disc in the “valve cage” / Photo: HK

The breathing valves of the “Lieutenant Lund I” were located in the hose connections on the side of the scrubber (Photo 17) and contained valve discs made of “Mica”, a mineral from the group of “layered silicates”. Dräger used these in valves for various respirators. Valve discs made of mica were very light, functioned permanently with much less wear than the “flutter valves ” made of rubber at the time, and had a high degree of stability. However, the small, lightweight precision compression spring made of stainless spring steel wire for pressing the valve discs was the weak point of the design (Photo 18). The high concentration of O2 and CO2 in the breathing air led to a redox reaction even with this hardened steel and thus to multiple replacements.

The successor to this “Lieutenant Lund I”, the Dräger “Lieutenant Lund II” (see later description) therefore later received a new lightweight rotating valve nozzle made of seawater-resistant polymer with integrated breathing valves and valve discs made of rubber. The elasticity of these “rubber flutter valves “, which are still used today in almost all regulators, made a compression spring unnecessary.

Although pure oxygen rebreathers can in principle be used without a BCD, there must be a balance between buoyancy and negative weight. To achieve this hydrostatic balance, the “Lund I” (as well as the “Dräger Kleintauchgerät 138”) was equipped with special flat counterweights in the form of a vest pocket (Photo 19). At a maximum diving depth of 10 metres, the optimum “floating position” of the device was between four and five meters with a lightly filled breathing bag.

Photo 19: Flat weight plate for Dräger oxygen circulation pumps in “vest” design, weight: 3 kg / Photo: © HK

Inhalation and exhalation (according to Archimedes’ principle), as well as manually adding oxygen through the bypass valve during descent or venting excess gas through nose and mouth during ascent, made for a finely trimmed dive. Of course, this calculation did not take into account the buoyancy of the diving suit, which had to be compensated with an additional weight belt.

Photo 20: Tightening the fastening straps of the Dräger “Lieutenant Lund unit I + II” / © Dräger Archive, Photo: HK

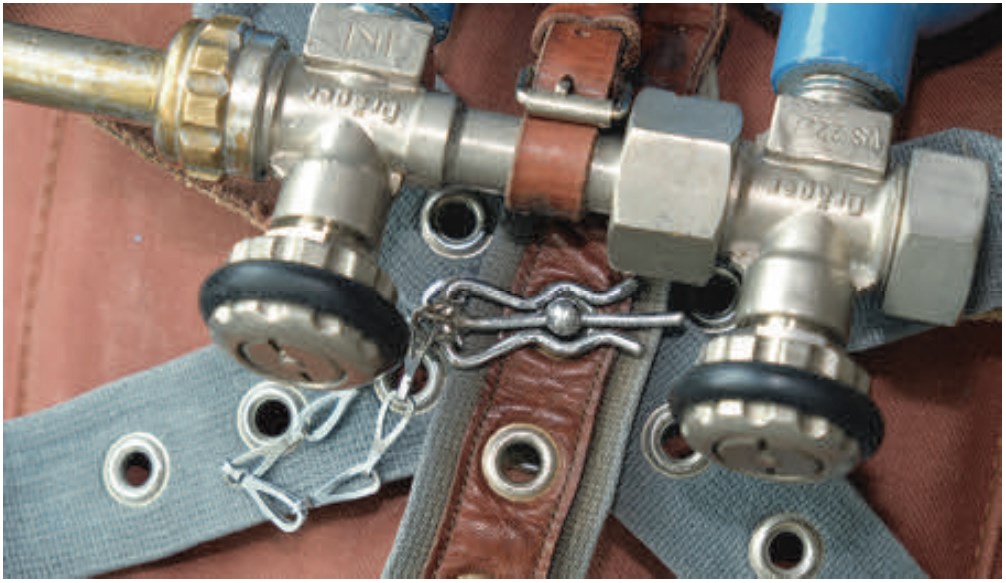

The rapid donning and doffing of an oxygen rebreather is indispensable in military operations. The prerequisite for this is a carrying and fastening system that can also be operated blindly under water. The vest, consisting of a front and a back part, was lifted over the head by the shoulder parts and lowered to the shoulders through the main cut-out; O2 bottles in the front, breathing bag in the back. The two parts of the vest “are fastened together by two side straps and a crotch strap (Photo 21), hooking them to the bolt of the quick release buckle ” … “First, the crotch strap is hooked to the bolt, then the side straps through the eyelets on the side of the chestpiece and attached to the bolt one by one. A safety pin prevents the straps from slipping off again” (Photo 20) [6].

Photo 21: Guiding the Dräger’s fastening straps “Lieutenant Lund devices I + II” / © Photo: HK

According to the current state of the art, this attachment variant may seem a bit “old-fashioned” and hardly allows the device to be put on and taken off quickly. However, former combat swimmers from the 1950s/60s confirm the opposite. Sufficient training led to amazing records. This central lock could be opened with a single hand movement, allowing the diver to disengage from the device in an instant.

Understandably, the new “Lieutenant Lund I” brought significant improvements in usability for more extensive tactical operations (Photo 23). This oxygen diving device was not only used by the Norwegian Navy’s “Froskemenn”, but was also introduced in limited numbers to other Scandinavian naval units (Photo 22). It is unlikely that it was delivered to other nations, as the “Lieutenant Lund II” was completed by Drägerwerke only months later.

Photo 24: The “Froskemenn” of the Froskeman School Horten, Norway 1954, with the Dräger ” Lieutenant Lund II” Bottom row (with French compressed air equipment) from the left: Ove Lund, Steinar Wickmann , Kjell Iversen , Peter Berg and two unknowns / Image: Dykker – og Froskemannskolen , Photo: © Erling Crane

Photo 22: The Dane Jan Uhre with the “Lieutenant Lund I” (Dräger model 138L) for his underwater crossing of the Baltic Sea from Rødbyhavn to Fehmarn in 21.5 hours in 1953 / Photo: Drägerheft 224

Photo 23: First missions with the “Lieutenant Lund I” in 1953 /

Source: ” Handbok for Dykking i Sjøforsvaret KNM Tordenskjold , Dykker – og froskemannsenteret “.

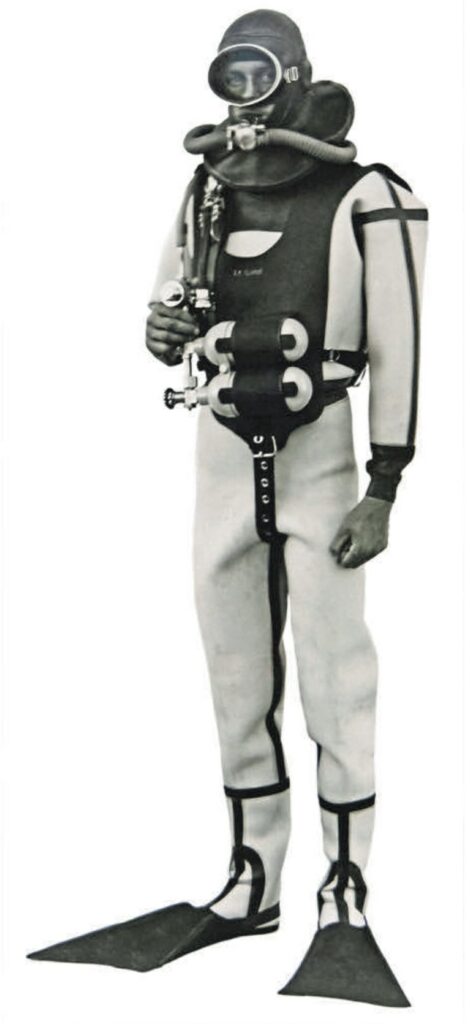

The diving suit for arctic operations

According to the records, the Norwegian Navy used not only the “Viking” dry suit mentioned above , but also the “Dräger 150” cold water dry suit (Photo 26). These two-piece swim-diving suits consisted of a “cold-elastic”, neoprene-coated white rubberized fabric with a quick-release fastener at the waist. The hood was firmly attached to the upper part. This was accompanied by an undersuit combination (photo 25) of the same material with a sleeveless vest and shorts. The production of these cold packs took place in December 1954 in the Dräger factory in Lübeck.

Whether the white color was due to the cold elastic material or also served as camouflage for arctic winter operations can only be speculated. It was also not possible to verify the extent to which these suits were used by the Norwegian School of Frogmen in practical operations. Based on the available data, it can be concluded that Lund also contributed his ideas to this special design.

Photo 25: Dräger undersuit combination for the cold water diving suit model 150, white / © Dräger, photo archive no. DL 16639, 1954, photo: HK

Photo 26: Dräger cold-resistant swim suit Modell 150, white. The diver is wearing the Dräger “Lieutenant Lund I” diving equipment / © Dräger, Photo Archive No. DL 166307, 1954, Photo: HK

Compressed air for the frog school

At that time, Lund was busy with additional duties for his unit. It was time not to limit yourself to underwater operations to a diving depth of 10 meters.

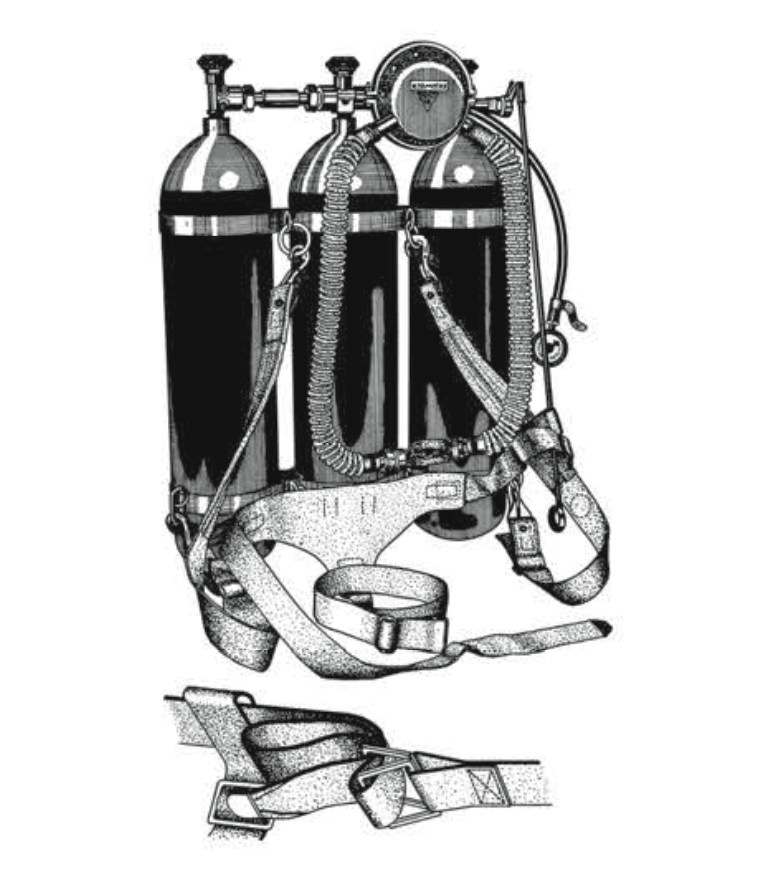

In 1954, the Froschmann School was equipped with French compressed air diving equipment, each with three 7 liter cylinders, 200 bar working pressure and a two-hose automatic breathing apparatus of the “Mistral” type (photos 24 and 27).

“Now the department could finally start diving,” like Erling Krange jokingly writes.

In 1955 the training of light divers for use aboard naval vessels began. The trained “on-board divers”, who were also under the command of Lieutenant Lund, had to be able to carry out simple tasks up to and including soil investigation.

Thanks to the close cooperation of the Norwegian Navy with Drägerwerke, Lund had the compressed air equipment supplemented in 1956 with Dräger devices of the ” Pazific ” design. These also consisted of three 7-litre cylinders (version PA 60/21, Drawing 28) with a working pressure of 200 bar and Dräger two-hose automatic circuit breakers of the two-stage type “PA 60/2”. The unit included a backup circuit that released the residual air if the tank pressure dropped below 35 bar after the pull rod was actuated, as well as an additional pressure gauge on a high pressure line.

Photo 27: In 1954, “Heavy Loaded”. French “La spirotechique ” scuba diving equipment with two – hose regulators of the “Mistral” type. Lieutenant Lund (in the background, left) and Per Berg ( hooded ) / Photo: Bjørn Bjørnø , Source: Erling Crane

The price of a complete device including two-hose automatic was then about DM 950.00 in Germany.

Drawing 28: Drawing of the Dräger three-bottle unit model ” Pazific ” with pressure gauge and backup circuit. / Drawing from: ” Beskrivelse af svømmedykkermateriel . Udarbejdet af P. Jarlskov , April 1957″.

But even the breathing gas supply of these three-cylinder devices with 4200 liters of air was not sufficient for longer underwater activities. Locating, identifying and repairing objects at depths of up to 20 meters required a different diving system whose working time was no longer limited by the air supply and which was easier to handle than a 3×7 liter tank pack. At the beginning of 1956, Drägerwerke launched a lightweight diving device with a compressed air hose especially for these tasks. “For some work to be carried out under water, the use of a helmet diving device is too cumbersome or too expensive, while on the other hand, the light diving device with compressed air cylinders is out of the question due to the limited diving time” – as Dräger writes in brochure 3-11 / G, 1st edition, May 1956.

Photo 29: Ove Lund demonstrates the ” Narghilé ” hose diving device Dräger model PA 60/S / Photo: DFS, source: Erling Crane

This gap was filled by the PA 60/S compressed air diving system. It was designed for a diving depth of up to 20 meters and weighed only about 8 kilograms. In 1956 , Ove Lund equipped the Frogman School with this so-called ” Narghilé ” scuba diving device (Photo 29).

Photo 30: Dräger compressed air diving apparatus PA 60/S with the Dräger two-hose regulator PA 60, in a sturdy protective housing / Source: Dräger brochure 3-11 / G, 1st edition, May 1956

In principle, this device consisted of the already introduced Dräger PA 60 two-hose regulator . The PA 60 was carried on the back in a sturdy protective cover with straps (Photo 30). The breathing tubes for separate inhalation and exhalation made it possible to connect a mouthpiece or a face mask. The 20 meter long air supply hose, which was passed under one arm, was connected to a compressed air bottle on the surface with a working pressure of 200 bar and a pressure regulator set at approx. 12 bar intermediate pressure. The air supply hose also served as a signal line.

According to information from Erling Krange [7] this hose diving device was later supplemented with a small additional compressed air cylinder that was worn on the back for additional safety.

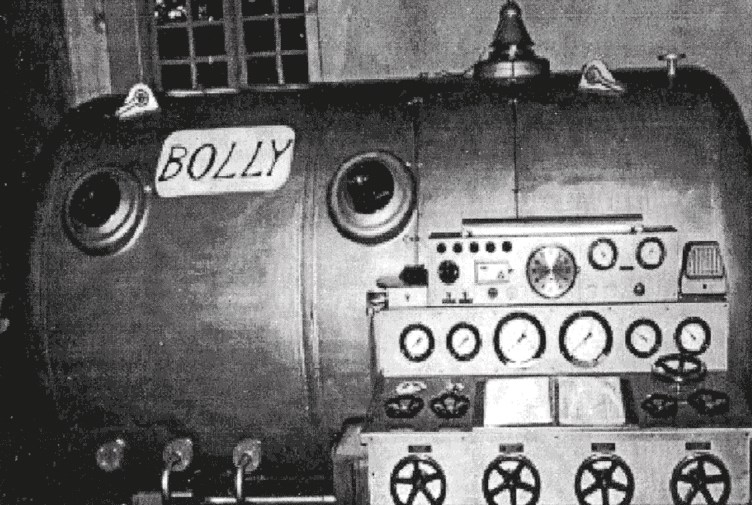

The stationary pressure chamber

The addition of compressed air equipment to the Froschmann School in 1955 presented divers with new challenges. The deeper standard air breathing gas dives that became possible required a larger pressure chamber.

Although a transportable Dräger Telescopic pressure chamber for one person was already available – already fitted with a bayonet connection (instead of bolted as in previous versions) – a stationary pressure chamber for several people was missing.

As early as 1954, the route for financing such an expensive project was set out by the High Command of the Navy and approved by the ministry. Once again Lund (now Lieutenant Captain) was given the task of discussing the technical details with Drägerwerke in Lübeck. The ” two-lock ” multi -personnel room was then built by Dräger in early 1955 specifically to Lund’s specifications. In early July 1955, the completed pressure chamber was ready for the ” Marinens Froskemannsskolen Horten” in the Dräger factory.

On the evening of July 18, 1955, a general operating test was carried out without people at a test pressure of 10 bar, the results of which could be concluded successfully [8]. The next morning, July 19, 1955, the acceptance “chamber test” with several people took place in the Drägerwerk. The following subjects took part in the test:

Captain Lieutenant Lund, Engineer Karlsen of the Norwegian Technical Marine Testing Center and Engineer Achler of the Drägerwerk.

The chamber pressure was first brought to 3 bar and then increased to a maximum pressure of 6 bar, the main chamber and the antechamber being tested separately (exposure times are not included in the July 20, 1955 memo).

When the pressure in the chambers was reduced, the oxygen system was activated. It was checked whether the working pressure of the oxygen equipment needed to be increased to 3.5 bar if necessary to prevent possible breathing difficulties. Temperatures in the chamber reached about 40°C through compression heat and the lowest temperature of 13°C during descent.

Photo 31: Dräger’s ” Two-lock multi-person pressure chamber for the Marinens Froskemannssko – ling Horten” 1955. side view / DFS, source: Erling Crane

Photo 32: Dräger’s ” Multi-person pressure chamber with two locks for the ” Marinens Froskemannssko – len Horten” 1955. Entrance view / Photo: Bjørn Bjørnø , Source: Erling Crane

The next day, July 20, 1955, a second test took place.

July 20, 1955, all valves were retested for their operation, as well as the pressure balance between main and anterior chamber. Participants in the second test were Lund and Achler . The system was then rated “technically ready for use”.

Lund confirmed that he was generally satisfied with the system. However, he requested that the following be changed before delivery: the existing eight door handles had to be reduced to half, a loudspeaker system had to be retrofitted, the blow-off speed had to be increased by enlarging the valves and tubes, the instrument boxes had to be painted silver-grey and the sliding rails in the main room for a stretcher had to be easy to remove. [8]

The changes were made in a short time and just four weeks later the pressure chamber was delivered by Dräger-Werke to Horten/Norway and installed in the ” Marinens Torpedo- og Mineinspeksjon ” (Pictures 31 and 32). It was nicknamed “BOLLY”.

The oxygen diving device “Lieutenant Lund II”

(Dräger drawing no.: T3600)

In principle, the oxygen rebreather “Lieutenant Lund I”, with which the frogmen of the Norwegian, and in the meantime also of other Scandinavian navies, dived, is largely fully developed and usable for military use. Nevertheless, there was soon a need for technical corrections, which Captain Lieutenant Lund had carried out in 1954 according to his specifications and in consultation with the leading Dräger engineer Hermann Tietze .

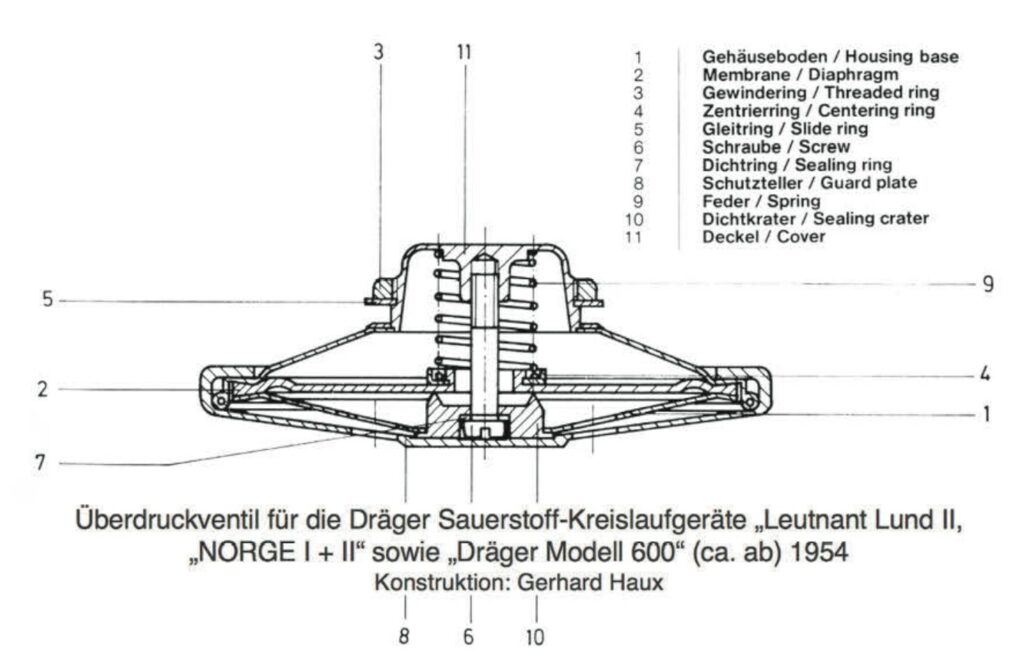

The main problem was the regular failure of the pressure relief valve. The pressure relief valve of the “Lieutenant Lund I” had been adopted from the “Dräger 138 Kleintauchgeräte”, where it had worked fairly reliably for civilian use for many years. However, the valve on the back of a combat diving gear is exposed to other stresses in the field and quickly stops working. Valve disassembly and cleaning were the order of the day. In his younger years, Gerhard Haux , later chief engineer at the Drägerwerke, was commissioned by his boss at the time, Hermann

Tietze , to design a new pressure relief valve (Drawing 33) for the “Lieutenant Lund device”.

Gerhard Haux wrote in 2002:

“Of the many details that needed improvement at the time, I must particularly emphasize a pressure relief valve for the respiratory lung, which in its original construction was a source of constant annoyance. This valve was made of pure brass and fitted with a spring- loaded sealing cone that was carefully ground, but leaked at the slightest contamination.

Drawing 33: New pressure relief valve for the Dräger “Lieutenant Lund II” / Drawing © Dräger Archiv , Edited by H. Knüfermann

Not to mention the so-called cold welds, which hindered the correct opening of the valve after a longer storage period. With a lot of stomach ache, I finally found a solution that solved all the problems in one fell swoop. The new pressure relief valve for the respiratory lung was deliberately equipped with a diaphragm transmission. The sealing takes place on a stainless steel crater with the relatively soft neoprene diaphragm, reinforced by a precisely balanced spiral spring. The valve opens with the desired setting extremely reliably, precisely, silently and is immediately ready for use, even after months of rest. Sensitivity to fouling is minimal, as any foreign matter on the seal crater is elastically contained by the soft membrane. This development has existed for more than 30 years, but is still relevant today. What more could a designer wish for?” [9]

This valve was set for the breathing lung with a 15 cm water column and also worked without problems with the later Dräger oxygen rebreathers in the “Western” version.

In addition, the position of the oxygen bottles has been adjusted. The two oxygen cylinders horizontally superimposed on the bib of “Lieutenant Lund I” proved “unfavorable to flow” and were changed to a vertical design for the “Lieutenant Lund II” (Drawing 34 and Photo 35). A small but effective correction that should have a positive effect with longer swimming.

Another modification of the “Lieutenant Lund I” concerned the mouthpiece. The inevitable entry of water into the mouthpiece – especially after re-hanging the previously worn device underwater – and the resulting “sloshing and gurgling” that not only made breathing unpleasant in the long run, but also produced noises that – however small they were – were carried by the water. This did not meet the military requirement for noiselessness. The only way to remedy the situation without air bubbles was to drink or drain the water by twisting the body and dumping the water through the exhalation tube and exhalation valve. However, lime that becomes wet as a result can reduce the absorption capacity, resulting in a risky increase in the CO2 concentration in the breathing circuit.

According to Lund’s suggestion, Drägerwerke developed a new nozzle for the “Lieutenant Lund II”, which could also be closed off, but with a manually operated drain

Drawing 34: Dräger “Lieutenant Lund II”, schematic representation / Source: Dräger manual, photo: HK

screw into the extended lower part of the housing (Photo 36). By briefly turning this screw counterclockwise, the water-filled area was slightly opened and a moderate burst of air could be exhaled while pinching the exhalation tube at the same time. An improvement, but still not completely free of bubbles. Later a chin rest was designed to relieve the biting muscles (Photo 36). The weight of the mouthpiece was just under 0.5 kilograms above water, and slightly less underwater due to the buoyancy of the air-filled breathing tubes. It was not until the later versions of the “Lieutenant Lund II” that a lighter rotating mouthpiece made of seawater-resistant polymer was fitted, incorporating the control valves that, as described, had previously been in the breathing hoses on the scrubber side of the device .

As with many diving devices requiring adjustments, especially through military experience, the ” Froskemannsskole ” has also repeatedly corrected individual problems that cannot all be listed here. However, one of the constructions should be briefly described.

Instruments worn on the forearm can only be read if the arm can be moved freely in the field of view. This is (also) not always the case during military operations. In order to check the depth while diving and to ensure a continuous compass bearing, a holder was designed for both instruments, which were attached to an individually adjustable holder on the gyro unit “Lieutenant Lund II” and were thus constantly in view during the dive. swimming. For a while all “Lund devices” were equipped with this (Photo 24 and 38). [10]

Photo 35: Dräger “Lieutenant Lund II” (one of the first photos from 1953, still with the old mouthpiece of the Dräger

“Lieutenant Lund I”) / © Dräger Archive, Photo: HK

Photo 36: New mouthpiece of the Dräger “Lieutenant Lund II” rebreather with drainage screw and chin rest / Photo: HK

Photo 37: Old Dräger mouthpiece of the rebreathers “Dräger Kleintauchgerät 138” and “Lieutenant Lund I” /

© Dräger Archive, Photo: HK

Today’s closed circuit oxygen equipment for military use is subject to rigorous testing for non-magnetic and non-sparking operation.

Photo 38: Instructor John Pedersen with compass and echosounder on the “Lund II” instrument bracket / Photo: DFS, source: Erling Crane

Mirrored to this, the diving device with oxygen circuit “Lieutenant Lund II” in the 1950s only insufficiently fulfilled these characteristics. On the one hand, the hydro -acoustic measurement methods for locating the sounds of approaching frogmen were not yet so electronically advanced, and on the other hand, mine diving was still carried out by Norwegian Navy helmet divers until 1967. It was not until 1968 that the Norwegian Navy established a special mine diving group.

A “non-magnetic” version of the “Lund” equipment was therefore probably not yet necessary for the frogmen of the school led by Lund. More precise information about this is not available. However, there are indications that Drägerwerke also supplied the “Lieutenant Lund II” in an amateur version to various naval units in the later years.

Almost all parts of the device could be pre-assembled in non-magnetic versions at the Drägerwerk. An exception were the oxygen cylinders made of ferromagnetic high-alloy steel. Demagnetization” was necessary for this.

The Dräger company entrusted the demagnetisation (using the alternating field method) of these cylinders to it “Magnetic Measuring Station Kiel- Friedrichsort ” via the “Testing Station 71 for Naval Weapons” in Eckernförde . This was carried out from 1956 according to the then new rules of the NATO Standardization Agreement (STANAG 1131).

However, ferromagnetic solids cannot be permanently demagnetized. Stray electrical and magnetic currents in the environment cause the loss of the magnetic signature. Thus, after measuring the magnetic remanence, repetitions were necessary at intervals.

Photo 39: From the front left, sitting: Bjørn Bjørnø , John Olsen, John Pedersen , Johnsen , Ove Lund (Head of the Frogman School), Kjell Iversen , Steinar Wickmann , Torleif Thomassen and Peter Berg. In the middle of the next row are three Danish naval officers who took the course in Horten – among them Børge Holm and Paul Jarlskov . Third man from the right in the back row is Trygg Anders / Photo: DFS, Source: Bjørn Bjørnø

The “Lieutenant Lund II” rebreather was introduced to many navies worldwide and proved its worth in countless missions. An overview of the purchasing countries and the number of units produced has remained hidden to this day. Yet this recirculation device, in addition to the English, Italian, French and American devices, was not only widely used in the NATO countries, but also ended up in Eastern countries via detours.

Endnotes and credits

[1] Bjørn W. Kahrs , instructor at ” Comex Diving”, dive leader for pressure chamber systems, offshore diver, studied history, former president of the Norwegian Baromedi – sinsk Association and the Norwegian Diving History Association and diving historian. Kahrs , B. W.: ” Kapteinløytnant About Lund. Forste chief for Marinens Froskemannskole ” Nordisk Dykkehistiorisk Timesheet 01/2017.

[2] Vidkun Quisling, Norwegian collaborator and National Socialist.

[3] ” Kjæseter “, a castle in Södermanland . During the Second World War, Kjæseter was used as a shelter for about 50,000 refugees from Norway and also by the so-called police forces.

[4] Draeger agreement and conference proceedings of December 12 and 13, 1952.

[5] [P. Jarlskov , April 1957 ” Beskrivelse af svøm – medykkermateriel .”

[6] Original description Draeger manual ” Lieutenant Lund II”.

[7] Krange , E.: FRA MARINEDYKKINGEN HISTORY I NORGE, Erkra Forlag Kristia – nsand 1994.

[8] Memo from the Dräger Archive of July 20, 1955 ( Exp.II /AC/Ti).

[9] Conversations with Gerhard Haux 2017 and 2018, and “Typical Haux “, Haux Publishing 2002.

10 ] Birkeland , E., former “Sjef for norsk marinens Dykker – og Froskemannskole ” Norwe – gen.

[11] Interview with Lieutenant Ove Lund. Appeared in an article in the magazine ” Vi Menn ” No. 5, from 1955 Kapteinloytnant Ove Lund, Forste chief for Marinens Froskemannskole “, by Bjorn W. Kahrs ) Norsk Dykkehistorisk Tidsskrift no. 1-2017.

[12] Report ” Fra Undersökelsenskommisjonen til etterforskning i anledning av inntruffend dods – fall ved froskemannsövelse i Horten den 13. august 1956″, Sjefen for Marinekommando Östlandet (“Report on the investigation into the accidental death during the exercise of frogmen in Horten on August 13, 1956”).

August 13, 1956″) Source: Norwegian Navy.

[13] Stationary Dräger multi -person double lock pressure chamber at the naval base ( Bolly ).

[14] Sven Erik Jørgensen ” Dykkede Lund med helium?” i: Dykkerhistorisk Tidsskrift , 2009 38/26.

[15] Jung, M., “Secret Project Meergeist , A 1944 Heliox Deep Diving Device” DIVEMASTER Nr. 74.

[16] “The Norwegian Navy has long been a top customer of Drägerwerk. For example, the famous oxygen recirculation devices for combat swimmers were developed together with Norwegian Lt. Lund, who subsequently also carried his name around the world,” wrote Gerhard Haux in 2002 in his book “Typical Haux .

The sequel to this impressive and carefully researched biography by Helmut Knüfermann: Lieutenant Lund – Biography of a Naval Officer (II), including acknowledgments and source references such as conversations, correspondence and literature.

in the next issue. It will mainly be about:

“Do you think diving to 100 meters is feasible?”

Lund reports on his first experiences with deep diving with mixed gas (NITROX) in an interview published in the Norwegian magazine ” Vi Menn ” No. 5, in 1956 [11].

Ove Lund: “Diving has significant physiological aspects – it is therefore necessary to acquire a thorough knowledge of human reactions to the pressure phenomena in the water and the oxygen and gas mixtures we use to breathe. It is important that we do not go deeper go beyond what can be fully justified by theory”.

Vi Menn : “Do you think diving to 100 meters is feasible?”

“With the improvement of the breathing systems we’re experimenting with, I believe we have the knowledge available for efficient dives up to 130 meters.”

Comment article: “This was indeed a surprising statement that will also interest frogmen worldwide. But especially Norwegian frogmen have to be able to dive twice as deep as in other countries because of there coastline”.

Helmut Knüfermann

About the author

Helmut Knüfermann, born 1944, member of the Historische Tauchergesellschaft eV , was a swim diver in the German Navy. After studying physics, he worked for 34 years in the research, development and sale of medical implants. He has been diving since 1958 and since his retirement has been involved in the history of Dräger oxygen rebreathers for military use, which he collects and continues to use. Six years ago he started to delve into the biography of the maker of his rebreather “Dräger Lieutenant Lund II”, with which he has been diving since 1969.

I would like to take this opportunity to thank Helmut for allowing me to share his thorough research and knowledge of this device with the readers of my website. It is therefore with great pleasure that a subsequent article part II about Lt Lund can be read hereafter! Helmut I am very grateful to you for this and a big compliment for your fantastic article!

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!