Alexey Konovalov sent me the article on the construction of the Euronaut. An incredible achievement by a group of volunteers. The initiator Carsten Stanfuss built this submarine for over 24 years. Read the story of a remarkable achievement!

Euronaut” research submarine

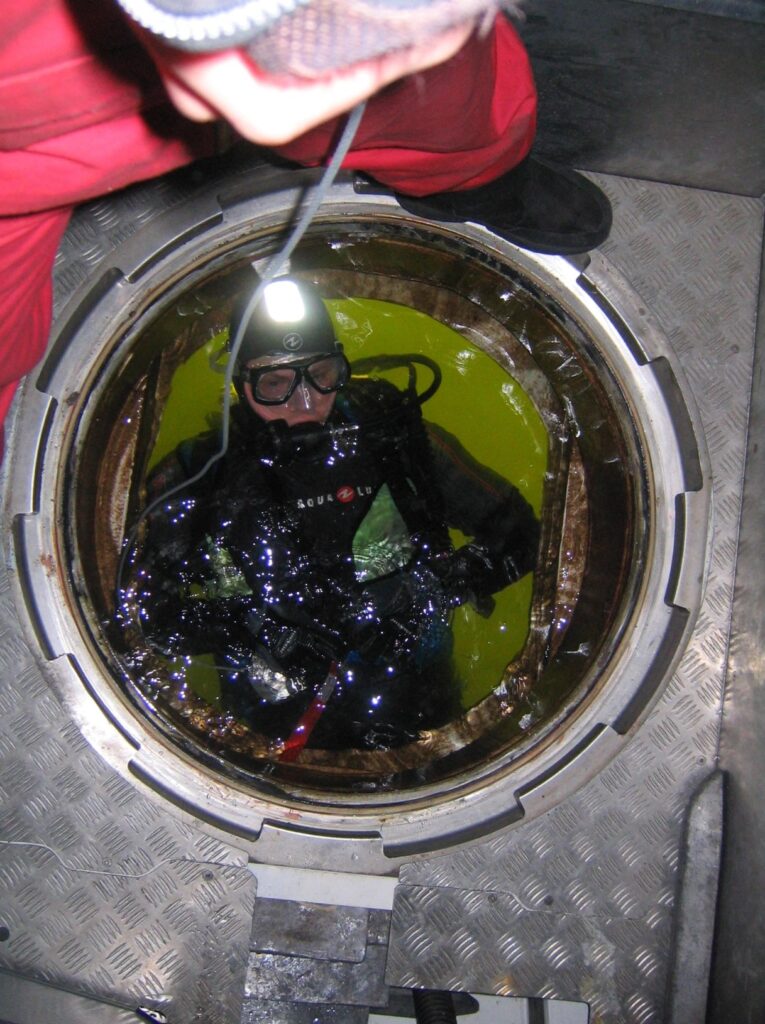

12 years of development, another 12 years of construction, 60 tonnes of material and a monetary value equivalent to two single-family homes. That’s the cost of fulfilling a childhood dream of having your own private submarine. I joined the “Euronaut” project in 2009 during my studies and supported it until 2020. In the eight years following the launch, I travelled a total of around 1250 nautical miles with the boat, made 37 diving trips and spent almost 17 hours in the diving lock at depth with half a dozen underwater exits. Basically, today I not only owe my diving as a life-filling hobby to the submarine, but also my professional career as a naval architect.

Project motivation

How does a recreational diver reach unexplored smaller or deeper wrecks far away from typical coastal diving areas if the cost of a sufficiently seaworthy vessel with sufficient deck space and accommodation is not worthwhile? And how do you gain a little more bottom time to survey and document these wrecks according to all the rules of the art without having to freeze for hours in decompression on a line afterwards? What do you do if you are only a private individual and

and have no access to the technical and financial resources of a research organisation or even the military? One possible, albeit very unusual, answer is to build your own submarine. Basically, this is exactly how the “Euronaut” was created – a diesel-electric research submarine for transporting divers.

One-man submarine “Sgt. Pepper’s”. Next to it Stefan Tietze with EXIVE rebreather developed in-house on board the diving and expedition ship “Fritz Reuter”

This project was initiated and largely conducted by the German naval architect Carsten Standfuß. At the age of 18, he built his first one-man submarine. According to the Guinness Book of World Records, his “Sgt. Pepper’s” was then the smallest manned submarine in the world, weighing only 575 kg when empty, and after all modifications, it could dive to a depth of 200 meters. Shortly thereafter, the idea of a much larger submarine arose, which was intended to operate as a mobile diving chamber and mother ship. The goal was to explore unknown wrecks in the North Sea at depths and in areas that are only accessible for short periods, if at all, for divers using conventional means.

The development of the submarine began in 1988 and accompanied Standfuß for 12 years, both during his studies and his professional life as a designer of search and rescue cruisers, government vehicles, and luxury yachts. The pressure hull, the most safety-critical part, was manufactured by a company specializing in the production of process towers and pressure vessels for the chemical industry. The rest of the vessel was built by Standfuß at the Lürssen Werft (formerly Schweers Werft) in Bardenfleth, Lower Saxony. The native of Bremerhaven was supported by a team of enthusiasts, mostly consisting of technicians and engineers. The circle of helpers extended to Denmark, Norway, and the Netherlands. In addition to the submarine itself, one of the team members at the time was involved in the development of a novel closed-circuit diving apparatus.

“Euronaut” on a factory site next to the developer’s house in August 2009.

After the hull was completed, the “EURONAUT” was transported to a nearby factory site on the Weser, which was separated from the developer’s house only by a fence. This allowed work on the project to continue after work, on weekends, and during holidays. After a total construction time of 12 years, the submarine was launched in July 2012 on the same site where construction had begun. In October 2013, Standfuß moved to Rostock, and the boat was moved on its own keel from its home port in Brake through the Kiel Canal to its new berth in the shipyard basin of Tamsen Maritim Werft.

“Euronaut” with two remote-controlled models at the launch in July 2012

During the long project period, the crew underwent various changes. At times, the team consisted of a good dozen volunteers who worked on the submarine, operated it, and participated in maintenance, depending on their available free time. Among them were also former submariners. The active core consisted of a handful of enthusiasts and the skipper himself, who also provided project funding. The costs for fuel, provisions, and other consumables for the outings were shared among the crew.

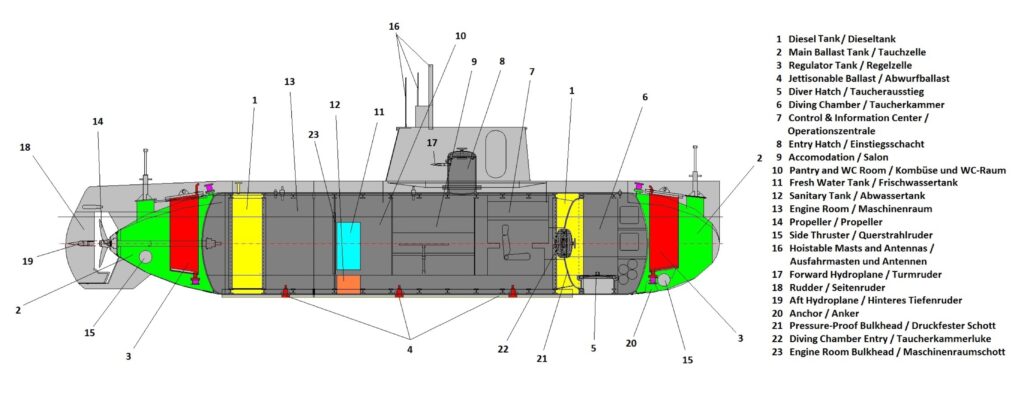

Mission Concept

The “Euronaut” submarine was developed for non-commercial use. The fact that it was created as a purely privately financed hobby project with very limited resources essentially determined the design and construction decisions made. The mission concept involves autonomous expeditions where no accompanying or mother ship is required. Unlike military submarines, it is a diving boat in the classical sense, which travels its transit routes exclusively on the surface. Only the search of a wreck area with its own sensors is done submerged in close proximity to the seabed, where optimal conditions for the use of active sonars exist. In shallow water, wreck searches can also be conducted from the surface. Once the position of the wreck is precisely determined, the submarine positions itself near it for diver operations on the seabed. Therefore, a large underwater range is relatively unimportant. Furthermore, the submarine lacks the ability to snorkel, as there is no need for a civilian vehicle to operate covertly. On the contrary, operational safety in maritime traffic requires visibility to commercial shipping and recreational boats or sailors.

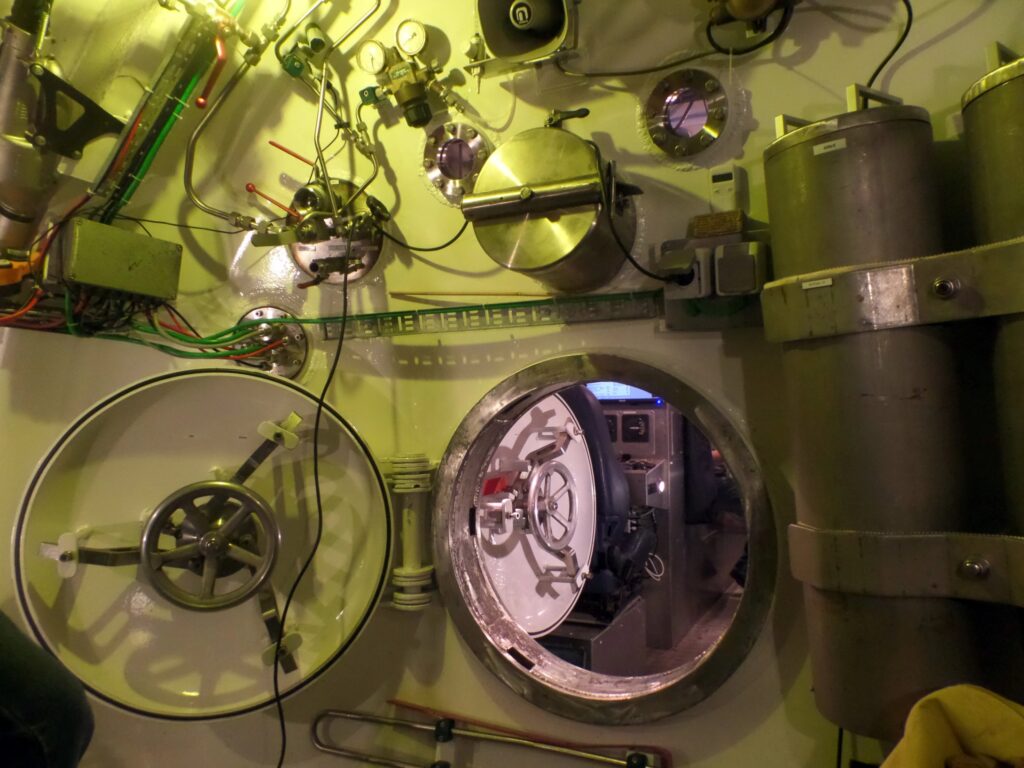

Boat’s Own Diving Lock

The heart of the submarine is an approximately 7.5 m³ 2-man diving chamber located in the bow and separated from the rest of the pressure hull by a pressure-resistant bulkhead. The exit is in the chamber floor. By deploying an anchor weight, a stern-heavy trim of approximately 5° can be set, causing the bow to lift off the bottom while the rudder rests on the seabed. This creates a sufficient gap over the bottom for divers to enter and exit. Divers can operate either with autonomous diving equipment or supplied from the boat. As long as the bottom hatch is open, the chamber remains at ambient pressure. This keeps it dry throughout the entire operation, as is known from diving bells used in the offshore industry. Additionally, the chamber is heated, equipped with two bunks, intercom with the control center, portholes for visual contact with the crew, and a medical lock. This allows for comfortable or health-preserving decompression with dry clothing, warm meals, and otherwise optimal conditions. Depending on the duration of the chamber ride, the submarine may already be on its way home or in port while the divers complete their decompression times. In fact, the maximum operational depth of the chamber depends only on the individual skills and equipment of the divers. Operations beyond 80 meters depth at the saturation diving limit are thus possible. As an additional function, it provides a refuge for the crew in emergencies if the main compartment, for example, had to be abandoned in a fire or flooding. It is equipped with autonomous air supply, a pollutant binding system, and barriers for emergency blowing of the front diving cell.

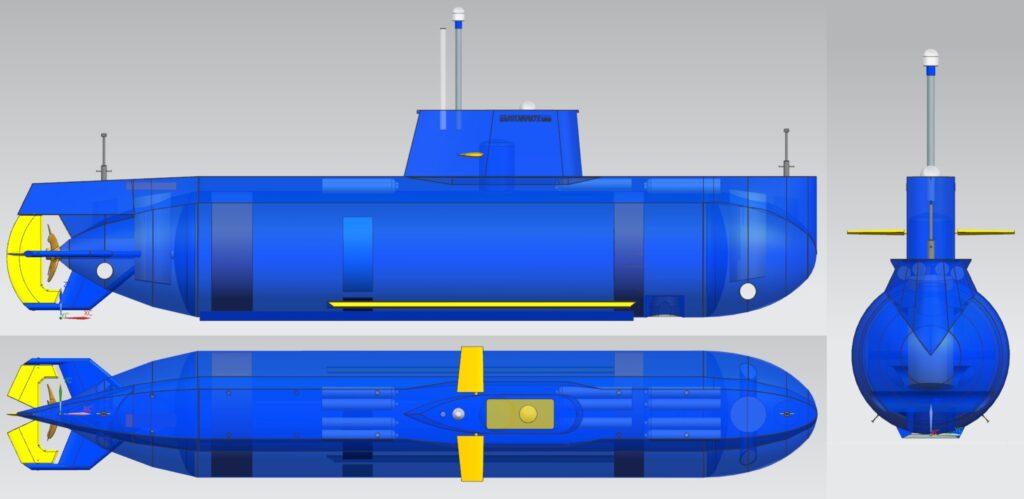

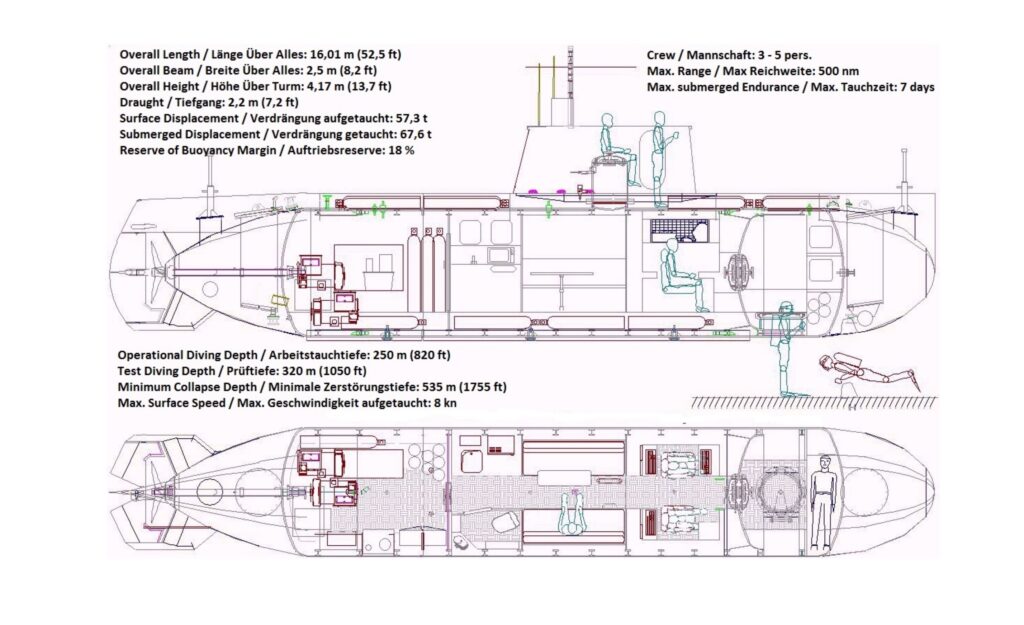

Basic Arrangement and Main Data of “Euronaut”

Design Features and Technology

The “Euronaut” is constructed in conventional single-shell construction. The main dimensions are chosen to allow for relatively simple road transport. To support this and to simplify construction or overhauls, the pressure hull is provided with a flange and can be separated behind the engine room bulkhead without cutting or welding work. The pressure-resistant access shaft and the lightweight tower structure are also bolted for quick assembly.

Shell construction between 2009 and 2010

The pressure hull is made of high-strength shipbuilding steel (S355J2) with a skin thickness of 22 mm. The frames are made of rolled double-T profiles, which, at the cost of slightly higher weight, achieve the roundness required for submarines inexpensively. By closing off two frame fields with thin sheets, fuel tanks with a total capacity of approximately 1.2 m³ diesel were formed inside the boat. The fuel tanks are pumped and not compensated with seawater. The bolted fresh water and wastewater cells are the only other internal tanks. There is no tank deck. Consequently, and with the help of an asymmetrical engine arrangement on the port side, a central aisle with headroom was made possible over the entire length of the pressure hull of 10 m.

A 192 hp suction diesel engine serves as the surface drive. It transmits its torque directly to the drive shaft via a reduction and reversing gear. Due to the offset of the diesel engine to the port side, the transmission had to be connected to the drive shaft via a timing belt. A direct current machine with 40 kW power, placed above the transmission, serves as the underwater propulsion, also acting optionally as a generator for charging the drive battery. The rest of the engine room houses two compressed air compressors from diving equipment, a small workbench, a fresh water generator, deep and shallow bilge pumps, part of the compressed air storage, and other auxiliary machines. For the sake of simplicity, a hydraulic system was dispensed with. All remote-controlled actuators are operated electrically by linear servo motors. Between the diving chamber and the engine

room is a central area with two workstations, a salon with two bunks, a small galley, and a toilet. Above it is the only access shaft. The drive batteries are not in a separate room but are placed in the salon under the bunks. The maintenance-free fiberglass mat lead-acid batteries used are gas-tight and can therefore be used without additional devices for hydrogen binding. Their total capacity is 160 kWh and allows about 4 hours of diving at 4 knots. All “hotel load” consumers are supplied by a separate “navigation battery” with a capacity of approximately 20 kWh. This provides underwater endurance of 1-3 days on the seabed and up to 7 days in an emergency. Air purification is carried out by several pollutant binding devices filled with lime and activated carbon.

Arrangement in the Engine Room and in the Central Area

On the outer hull, a diving cell is adjacent to each end plate. Inside the diving cells, combined pressure-resistant trim and control cells are arranged (“open trim system”). For the short diving distances, this arrangement is sufficient and simplifies boat construction. Overall, the project focused on cost-effective manufacturing and maintenance. There is a minimal number of pressure hull penetrations, and almost all external equipment is located on the upper deck, where it can be quickly accessed via the swiveling deck plating.

To protect the propeller during operation in close proximity to the seabed from damage caused by ground and wreck contact, the cross rudder is traditionally arranged behind the propeller and is effectively concealed by massive bearing brackets or the rudder heel. High maneuverability is ensured by the equipment with two transverse thrusters and a 500 kg trim plate. The trim plate is located in the salon under the hallway floor and can automatically compensate for trim moments by its longitudinal movements during diving operations.

Special attention was paid to the safety systems on board. The “Euronaut” has a centrally triggerable stationary fire extinguishing system with high-pressure mist generation, an emergency breathing system with detachable breathing regulators, and a total of 3 tons of drop ballast under the keel. In addition, the fire load of the diving chamber has been reduced as much as possible considering the high oxygen partial pressures during its operation. Most safety-relevant systems are redundant. Although all bulkhead closures are simple, their number has been reduced to the necessary minimum. An example of this is the engine cooling water system, which has a closed circuit with a heat exchanger under the keel. This eliminates the need for a chilled water unit and large sea water lines inside the boat. The same applies to the externally located trim and control system.

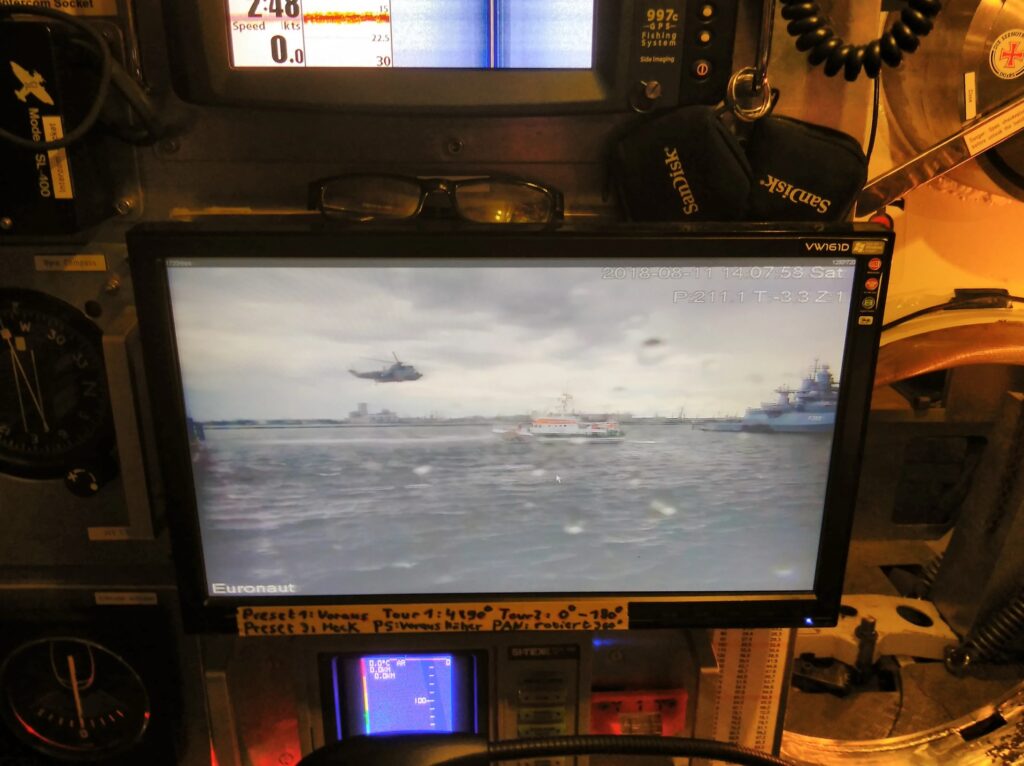

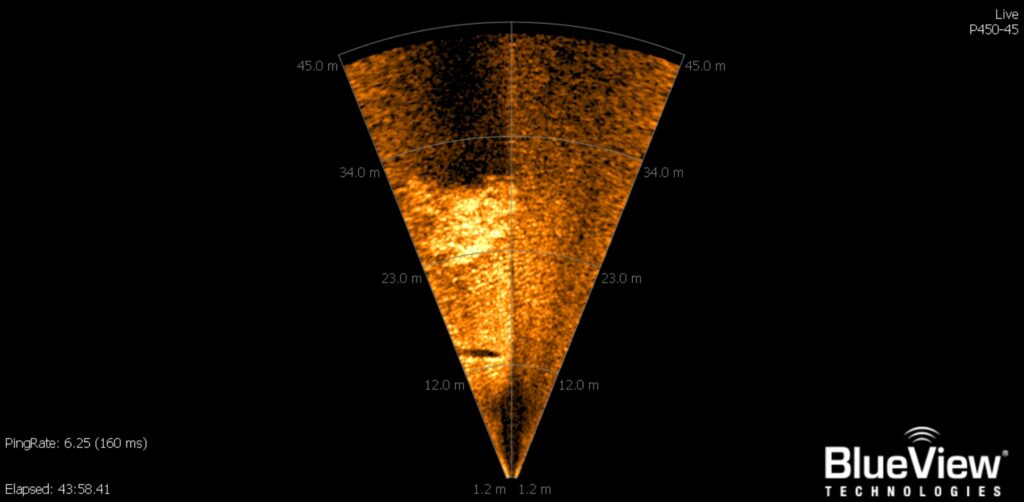

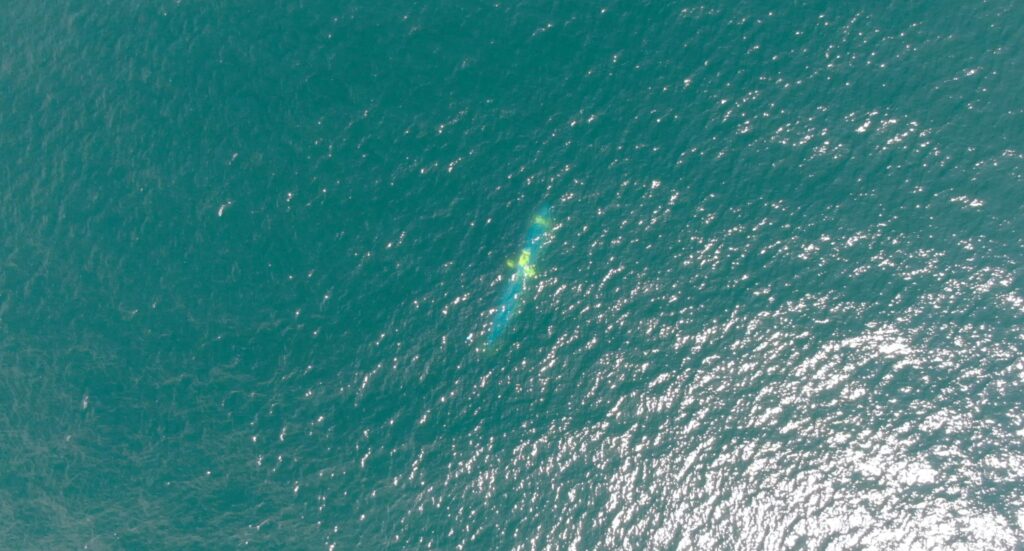

A low level of automation of the submarine is also part of its safety concept. Onboard computers are used exclusively for monitoring and not for control. Its own position and speed determination during surface navigation are done via a GPS receiver. Underwater, only a simple gyroscope compass is available. Given the very short underwater travel distances, there is no need for further technical support for couple navigation. Active sonars, which serve wreck search, collision avoidance, and determination of bottom conditions, are therefore of greater importance. The submarine is equipped with a forward-looking sector sonar, a side-view sonar with echo sounder functionality, and a forward-looking sonar that acts as a collision avoidance sonar. Optical reconnaissance is provided by a swiveling surveillance camera integrated into an optronic mast. Additional fixed cameras are housed in a multi-purpose mast, which also houses a GPS receiver, navigation lights, a UMTS modem for coastal mobile phone reception, and deck lighting. All masts are manually raised and lowered.

Missions sofar

During the first eight years since its commissioning, the submarine was in the testing and training phase. With the relocation to the Baltic Sea, long cruising trips along the Weser and in the Wadden Sea were eliminated, but the hobby nature of the project, or familial and professional obligations of the crew members, usually allowed only day trips. The targets were the closer-known wreck positions or striking geological underwater formations. Highlights included two longer expeditions in the Mecklenburg Bay and off the Danish island of Møn. During the first expedition in 2015, accompanied by a film crew, a six-hour dive with wreck surveying at a depth of 23 m took place. To date (as of April 2024), this is the deepest dive undertaken with the submarine. The second expedition was conducted in 2019 in cooperation with an environmental organization. A new anchor system was tested, allowing safe diver operations even at a depth of 6 m, which is physiologically much more challenging than at greater depths. Furthermore, the crew managed to locate a wreck recorded in nautical charts with sonars and position the submarine precisely 13 m away from the object on the seabed.

Since diving chamber operations were last carried out exclusively with compressed air as breathing gas, the maximum depth for underwater exits is limited to approximately 30 m. In the longer term, the diving chamber was to be modified for operation with helium-containing breathing mixtures. Until then, wreck explorations in greater depths were to be carried out using a wire-guided underwater drone (ROV) acquired in 2019. Since the end of 2020, the “Euronaut” has been undergoing a major overhaul at the Tamsen Maritim site, during which the boat is receiving a modernized rudder and propeller system, new compressed air storage, and batteries.

Carsten Standfuß with his “Baby”

Conclusion

Although the submarine was built by private individuals in their spare time, the result is a hobby vehicle that was built partly with used technology but was realized with a claim to professional implementation. Thus, it is probably unique in its kind. The shortcomings of the sometimes misappropriated technology were compensated for in practical operation by the multitude of redundancies. However, it was found in the course of the previous missions that the performance limits of the submarine were not reached. The reason for this was that the crew could not build up the required training and qualification level during occasional weekend trips. Nevertheless, the technical concept was continuously adapted and optimized until the “Euronaut” is intended to be suitable for use in greater depths in its final expansion stage. The previous depth limitation for diver operations was limited on the one hand by the personal training level and experience of the diving crew members and on the other hand by shallow water depths in the sea areas around Rostock. Nevertheless, the main goal of the project was achieved. “Euronaut” is capable of operating autonomously as a research submarine without auxiliary vehicles.

The original version of this article was published in the VDU (Verband Deutscher Ubootfahrer) club magazine.

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!