Selfmixing Swim apparatus

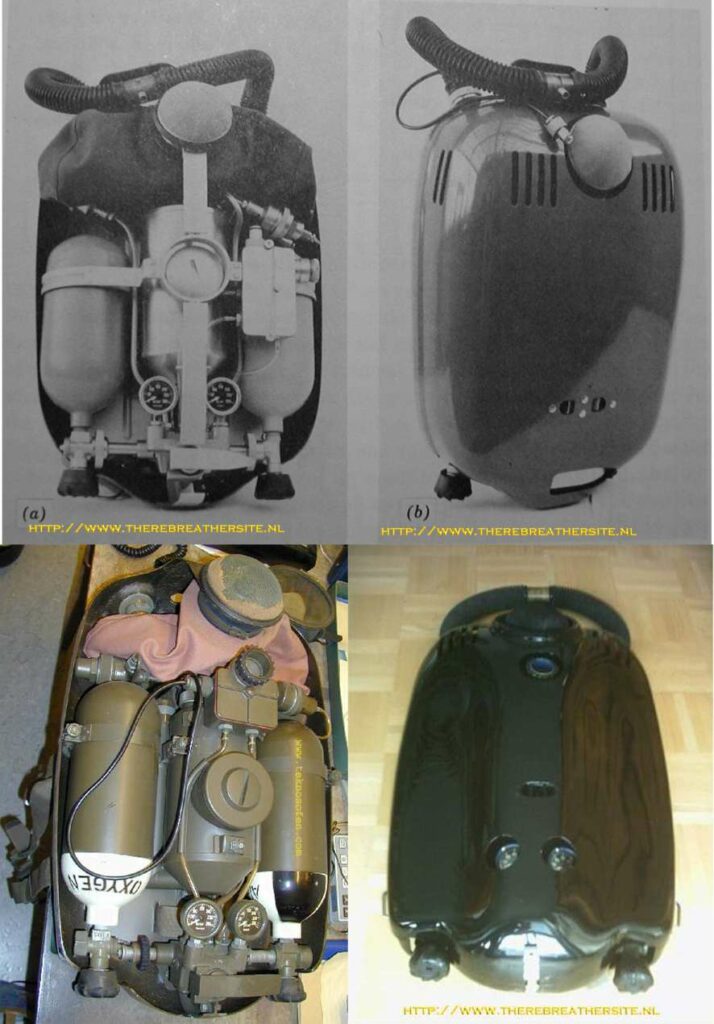

photo by Åke Larsson.

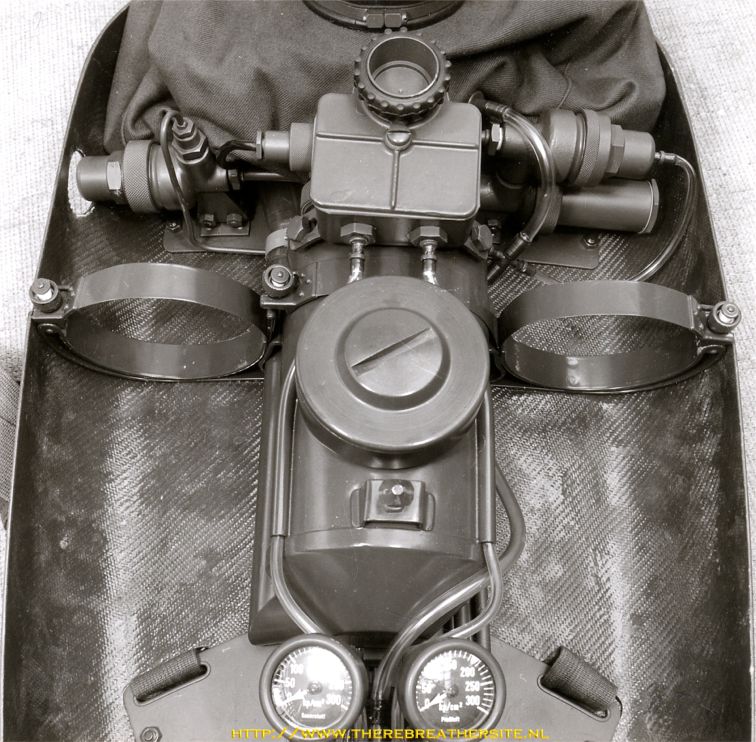

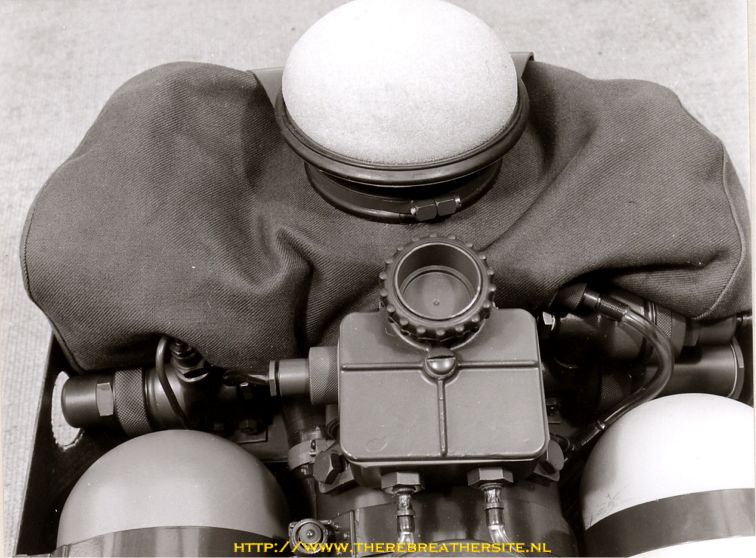

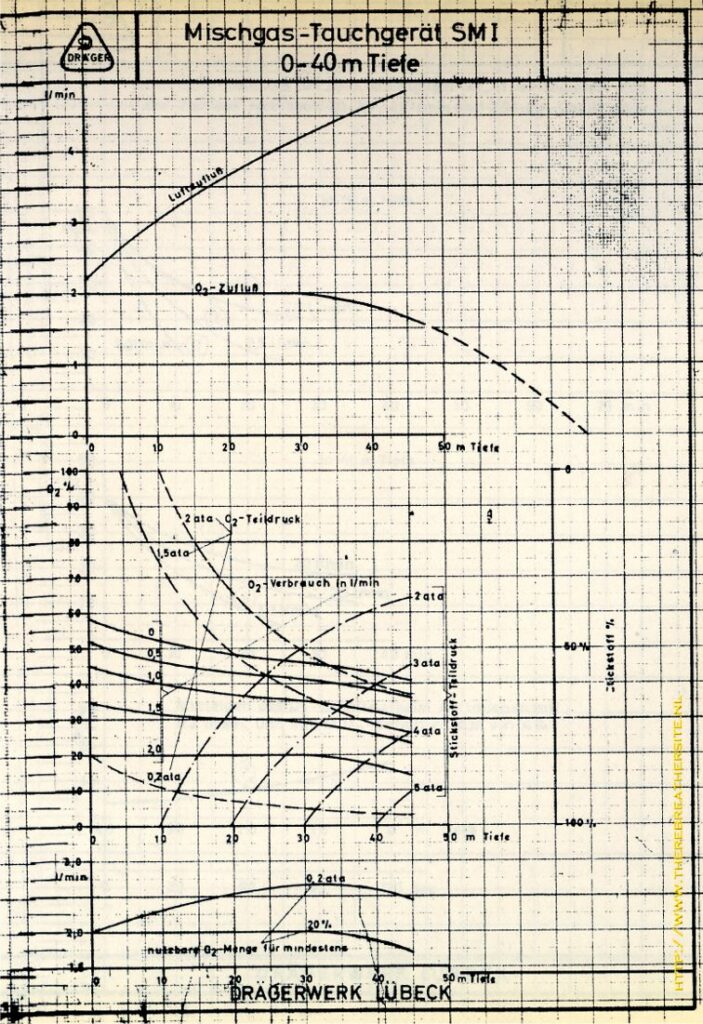

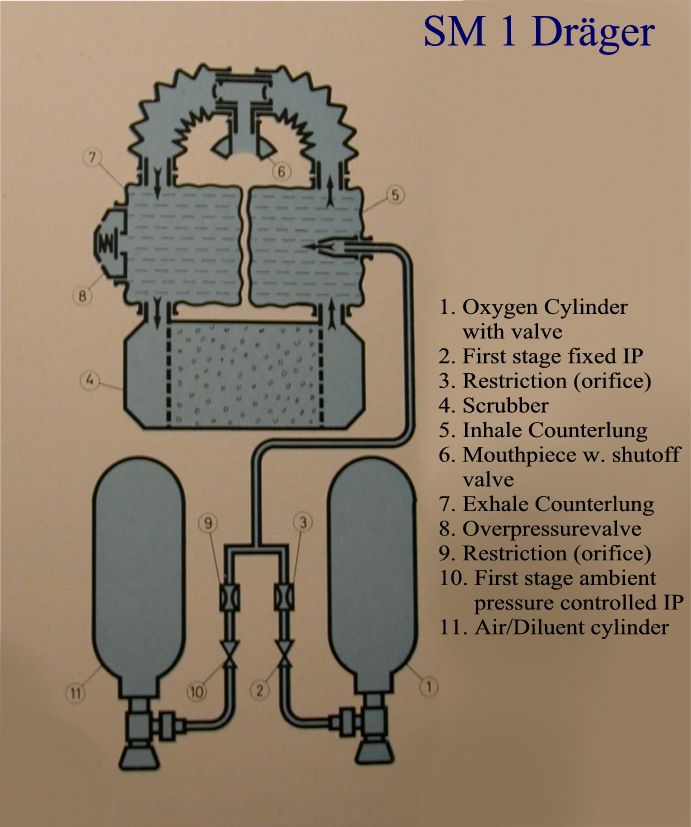

This unit is equipped with an oxygen and an air bottle. Both bottles have a volume of 1,5 ltr and 200 bar working pressure. Mixing the oxygen and air is done automatically by using orifices. The mix is changing with the depth. The carbon dioxide exhaled by the diver is removed chemically by the scrubber. The cleaned air is mixed with the ait-oxygen mix that is injected in the loop. The design is made in such way that 2 ltr/min oxygen consumption of the diver is possible. The lower fraction of oxygen pressure is restricted to 0,2 bar. When the diver uses 0,5 ltr oxygen per minute the unit will not provide gas with a higher partial pressure of oxygen above 2.0 bar. During a common use of 1,3 ltr/min oxygen consumption, the partial pressure of oxygen will be around 1,5 bar.

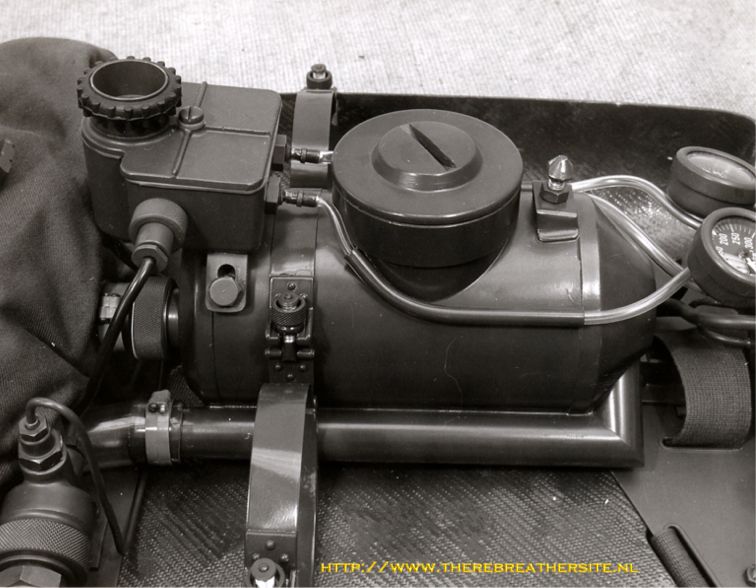

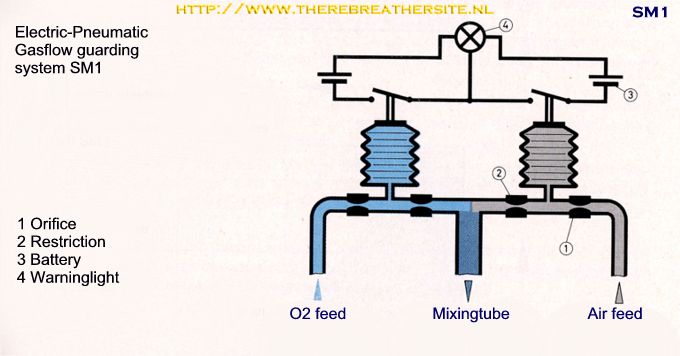

Oxygen is added by means of a first stage regulator with a fixed IP of 9 bar. Resulting in a constant oxygen flow of 2 l/min independent of the depth! Air is added by means of a depth compensated first stage regulator AND a second stage regulator reducing the IP being 0,5 above ambient pressure. (depth compensated). The gas is mixed in a mix tube before entering the loop. The system in supplied with two electric switches who guard the pressure between the restrictors, in this way warning the diver when the gas flow stops.

DATASHEET SEMICLOSED REBREATHER | |||||

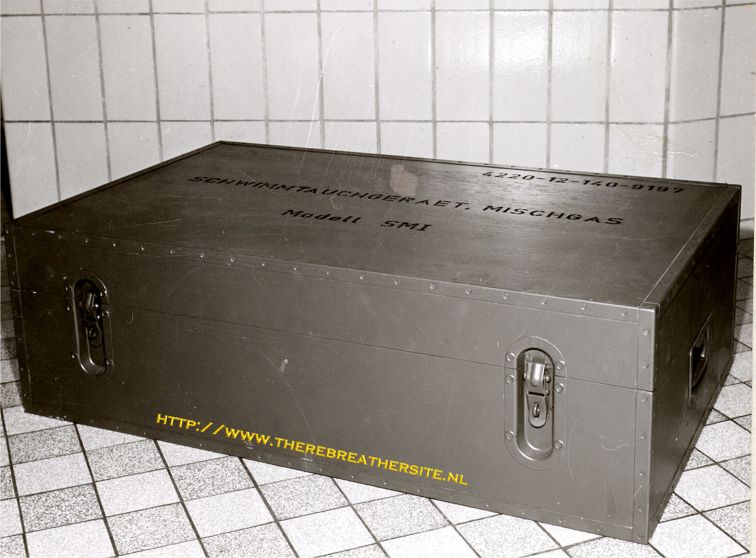

| Dräger SM 1 | Date: 11 April 2005 | ||||

| Selbstmischendes Mischgas-Schwimmtauchgerät SM1 | Database semi closed rebreathers by: J.W. Bech | ||||

| Manufacturer | Dräger | ||||

| Designer | |||||

| Model | SM1 | ||||

| Land of origin | Germany | ||||

| Design year | 1962? | ||||

| Special Note: | Rare rebreather | ||||

| User group | Military | ||||

| Magnetic characteristics | Non Magnetic/ Acoustic | ||||

| Part no: | 4220-12-140-9197 | ||||

| Working principle | Constant Mass Flow | Oxygen 2 ltr/min – Air 2,2 ltr/min | |||

| Gas type | Oxygen – Air | ||||

| Oxygen is added by means of a first stage regulator with a fixed IP of 9 bar. Resulting in a constant oxygen flow of 2 l/min independent of the depth! | |||||

| Air is added by means of a depth compensated first stage regulator AND a second stage regulator reducing the IP being 0,5 above ambient pressure. (depth compensated). | |||||

| The gas is mixed in a mix tube before entering the loop. The system in supplied with two electric switches who guard the pressure between the restrictors, in this way warning the diver when the gas flow stops. | |||||

| Intended use | Military | ||||

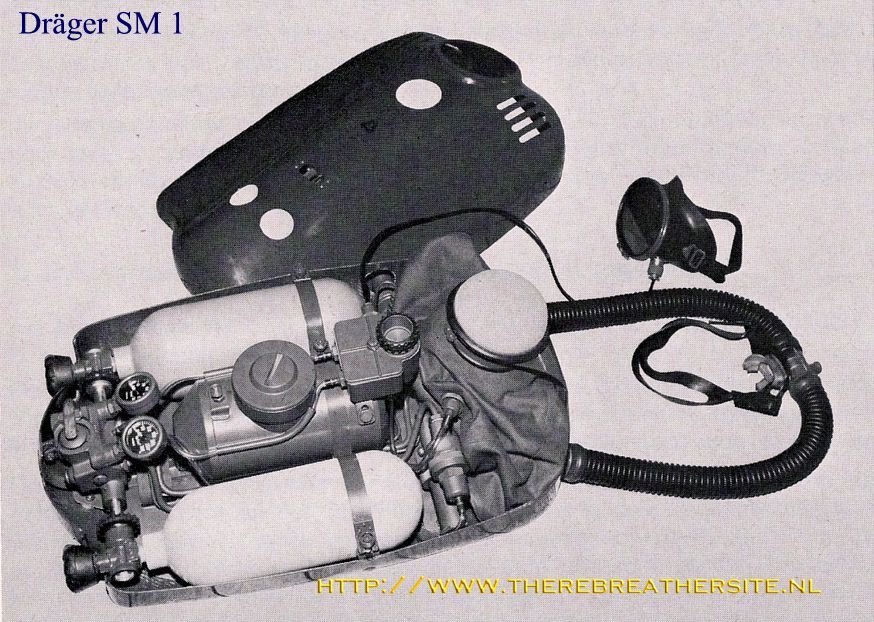

| Dimensions LxWxH | 640 x 420 x 270 mm | ||||

| Device weight | In Air 25 kg in water 4,0 kg | ||||

| Intermediate Pressure | 9 bar 02 fix/ Air Pamb+0,5 bar | ||||

| Overpressure valve | 15 cm water Colum | ||||

| Max depth | 40 meters | (metres) | |||

| Used material for housing/backplate | glass fibre | ||||

| Pressure reducer | Oxygen, fixed, Air depth compensated | Air 2 staged pressure reduction 10bar – Amb+0.5 bar | |||

| Connection reducer – bottles | Oxygen cylinder with inside thread, Air outside threat | Aluminium bottles 1,5 ltr max 200 bar | |||

| Supply pressure | 200 bar, minimum 30 bar | ||||

| Umbilical connection | No | ||||

| Color of cilinders | Air : Gray, Oxygen: Blue | ||||

| Manual bypass | Yes, by pressing lever both gasses are added | ||||

| pO2 measurement standard | No | Lamp guarding gas flow | |||

| Pressure gauge range | 0-200 bar | Lamp fitted in mask | |||

| Cylinders | 2 x 1,5 liters | ||||

| Cylinder material | Non-magnetic | ||||

| Cylinder thread | G 5/8” inside and outside | ||||

| Valve | T-shape | ||||

| Designed for gas type | Selfmixing | ||||

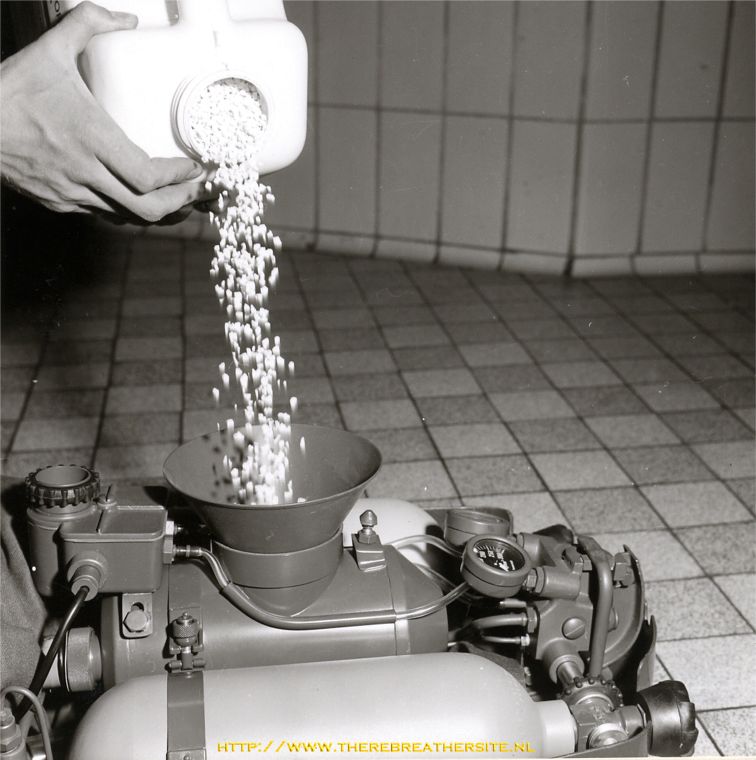

| Co2 absorption cartridge capacity | 2,1 liters | ||||

| Co2 absorption cartridge rechargeable | Yes | ||||

| Co2 absorption cartridge storage time | no data | (month/year) | |||

| Co2 absorption time testing (CE) | No | ||||

| Connections Co2 cartridge | The scrubber is fixed in the rebreather housing | ||||

| Guaranteed absorption time | 100 minutes @ 10 meter | ||||

| Grade of absorption material | no data | ||||

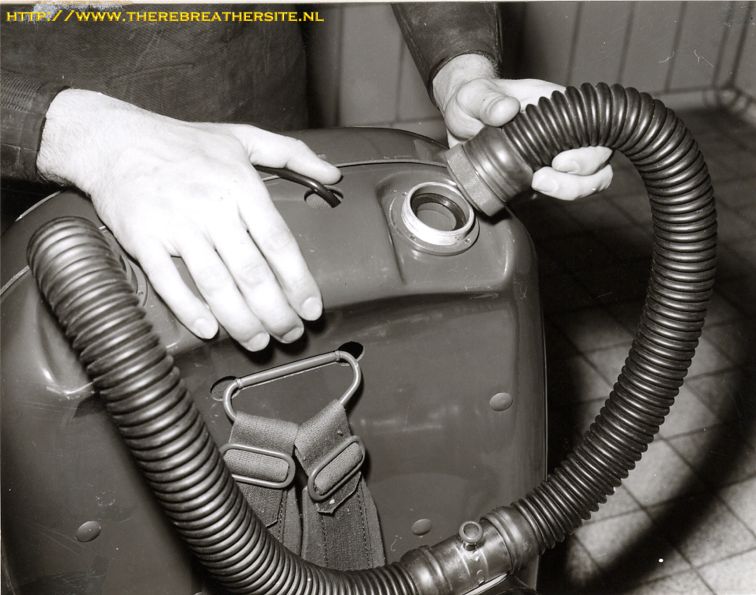

| Breathing bag material | inside rubberized | ||||

| Inhale bag volume | no inhale breathing bag | ||||

| Exhale bag volume | 10 liters fixed between exhale side and scrubber | ||||

| Total loop Volume | Total volume 11 liters | ||||

| Operating temperature | no data | ||||

| Magnetic signature | low | ||||

| Colour (s) | green | ||||

| Worn | On the back | ||||

| FFM attached | Yes | (mask) | |||

| Mouthpiece valve | Yes | ||||

| Extra info: | Low acoustic signature | ||||

| Safety device | The unit comes with a double pressure switch. In case pressure of one of the gasses drops below a certain safety level the switch turns on a small lamp in the divers mask. You can see the small cable fixed on the mask. | ||||

| Additional information: | http://www.teknosofen.com/draeger_sm_tech.htm | ||||

| Email address owner: | |||||

| URL owner: | |||||

| If you have any information to add this sheet please mail it to jw.bech@quicknet.nl References to source and names will always be added! | |||||

| Info found: Ake Larsson, Tauchtechnik G. Haux, Original Manual Dräger SM1 kindly offered by Nautiek Diving Netherlands | |||||

| Origin: http://www.therebreathersite.nl | |||||

| Info: | |||||

| The unit is equipped with an oxygen and an air bottle. Both bottles have a volume of 1,5 ltr and 200 bar working pressure. Mixing the oxygen and air is done automatically. The mix is changing with the depth. The carbon dioxide exhaled by the diver is removed chemically by the scrubber. The cleaned air is mixed with the ait-oxygen mix that is injected in the loop. The design is made in such way that 2 ltr/min oxygen consumption of the diver is possible. The lower fraction of oxygen pressure is restricted to 0,2 bar. When the diver uses 0,5 ltr oxygen per minute the unit will not provide gas with a higher partial pressure of oxygen above 2.0 bar. During a common use of 1,3 ltr/min oxygen consumption, the partial pressure of oxygen will be around 1,5 bar. | |||||

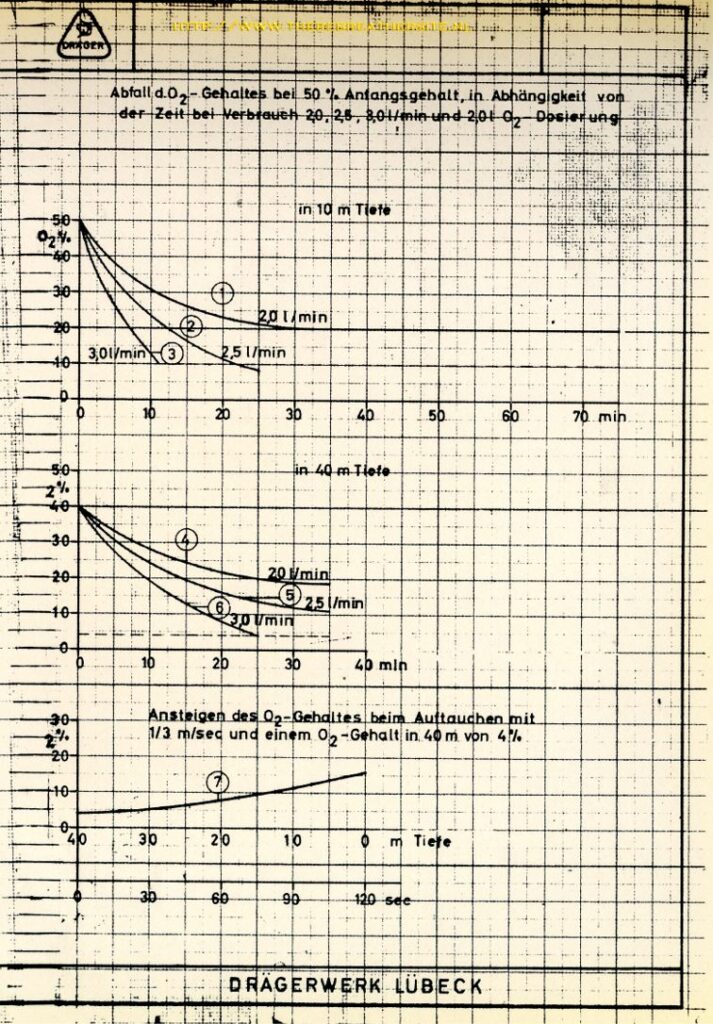

| Example: Suppose the diver dives to 10 mtr depth and has filled his loop with gas. The starting percentage of the loop is 50% of oxygen. When using 2,0 ltr/min (graphic 1) after 30 minutes the oxygen % will drop to 20% and reaches the lower limit. At 10 mtr water depth the loop lower limit is 10%. When using 2,5 ltr/min this lower limit is reached in 20 minutes (graphic curve 2). When using 3,0 ltr min in 10 min the lower limit is reached. | |||||

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!