This comprehensive article describes the development of oxygen diving equipment for military applications. I was allowed to publish the article written by Helmut Knüfermann on my website with his highly appreciated permission. The article gives an able insight into the development steps from the first beginnings to today’s advanced diving apparatus.

Chronological development of closed-circuit oxygen scuba diving equipment from the Dräger factory for military use

By Helmut Knüfermann

Our Author Helmut Knüfermann, born in 1944, was a swimming-diver (Schwimmtaucher) for the German Navy. After completing his physics studies, he worked for 34 years in research, development, and sales of medical implants. Helmut has been diving since 1958 (since 1969 with the Dräger “Lieutenant Lund II”) and, after his retirement, is involved with the history of Dräger oxygen rebreathers for military use, which he collects and still uses today.

In this article that consists of 4 parts describing a large number of oxygen rebreathers. To this end, a compact index is available. The article consists of 4 parts and there is a separate index for the types of diving apparatus.

part 1

Part 1: Kleintauchgerät 138, Kampfswimmergerät, Schwimmtauchgerät, Badetauchretter, Baderetter, Gegenlunge TR and Tauchretter

Part 2: Kleintauchgrät 138, Leutnant Lund I, Kleintauchgrät 138L, Leutnant Lund II, Norge I, Norge II, Modell 600

Part 3: LAR0, LAR I, Lar II, Lar IIa, Kar I, Lar IIc, Lar III

Part 4: Lar IV, Lar V, Katox

s1

s2

s3

s4

PART 1

Devices in “Vest” design up to and including “Dräger small diving apparatus 138”

This article is intended to provide an insight into the designs and constructions of the military oxygen rebreathers manufactured by Drägerwerke up to and including the “LAR V” device type. Later devices are not included. I have deliberately omitted the complex subject of diving physiology and diving medicine for diving with pure oxygen as a breathing gas, with the exception of a few details that are useful for understanding the functions of the equipment.

Descriptions of military strategies and operations are also not included, as only the special technical features of the diving equipment manufactured for this purpose are to be described here.

Parts 1 and 2 (in the following issue) of this article describe the history and, in the further course, the type chronology of the early devices in “Vest” design, made of rubberised textile fabric. The “hard-shell” devices made of glass fibre-reinforced polyester resin, which were manufactured at a later date and worn on the chest, are the subject of Part 3.

Sea fighter with reed snorkel

The trick of surprising opponents from the protective cover of the water is as old as mankind itself.

Stories of Indians who breathed underwater through reeds in order to overpower their unprepared tribal opponents have fascinated me since my youth.

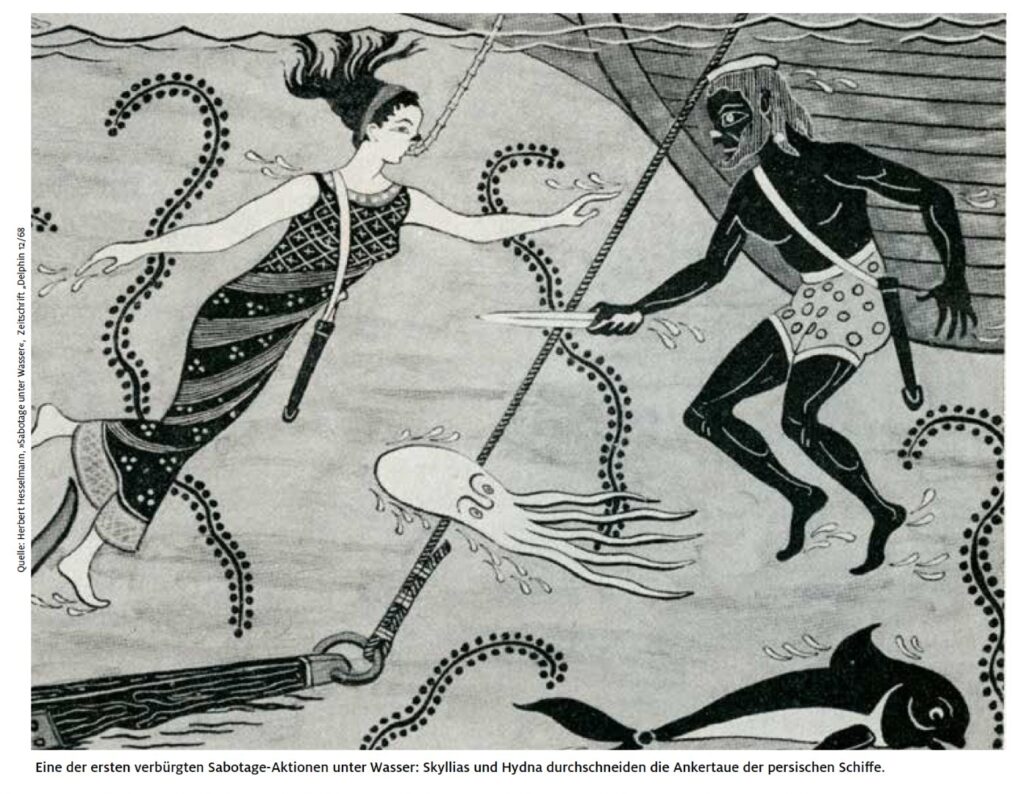

The first known records of underwater sabotage from Herodotus, 450 BC, refer to information from the Spartan military leader Pausanias about Scyllias and his daughter Hydna (Cyana), who cut the anchor ropes of Persian ships off the Greek coast with their sabotage [Picture 1]. The ancient Greek legend tells of “θάλασσα μαχητής”, meaning “sea fighters”.

Related terms can be found throughout ancient mythology, in which warlike actions under water are reported. In his epic about the Roman civil war between Caesar and Pompey, the Roman writer Lucan, 39 – 65 AD, wrote of the “mare pugnator” – “sea-rider”, which was passed down in later literature as “sea-fighter”. This lyrical transformation of the official term “swimming diver” was also used by the German Navy during the Second World War.

It was not until the invention of portable diving equipment in the 20th century, whose closed circuit did not allow any treacherous air bubbles to reach the surface, that it became possible to stay underwater for longer periods of time without a “reed snorkel”. This was of course of great military interest. It is therefore not surprising that the development of these devices was heavily subsidized by military impulses and funds. Many nations, particularly the Italians and the British, repeatedly designed new and better rebreathers, whose use caused a sensation, especially during the last world war. It was only natural that a German manufacturer with a long track record in the production of oxygen rebreathers for use above water should use its expertise to produce rebreathers for combat swimmers: the “Drägerwerke” in Lübeck.

History of closed oxygen breathing apparatus

Without the history of the oxygen breathing apparatus developed by Drägerwerke, this article would hardly be conceivable. Over the course of 70 years, the experience of the leading engineers Hermann Stelzner, Hermann Tietze and Gerhard Haux led, among other things, to the production of closed-circuit oxygen breathing apparatus for combat swimmers.

The first inventions of a portable closed oxygen breathing apparatus based on the principle of

generation with binding of the exhaled carbon dioxide by a chemically active substance date back to the middle of the middle of the 18th century. These devices were initially used in mining and rescue operations, where contaminated or contaminated or poisoned ambient air was to be expected. was to be expected. It was not until the Englishman Henry Albert Fleuss (1851-1933), originally a ship’s officer in the merchant navy, constructed designed an oxygen breathing apparatus that was also suitable for use for underwater use and was produced from 1879 in the factory for diving equipment. by August Siebe in London from 1879

The diving engineer at Siebe & Gorman, Robert Davis (1870- 1965), developed the rebreather together with Fleuss in 1903 into a diving rescuer. Thus, in 1903, the oxygen rebreather into the legendary “Davis diving rescuer”(DSEA) at the same time, Drägerwerke in Germany was working on oxygen rebreathers based on the same principle – initially for use by fire brigades and in mines. “The start of development of German diving rescuers based on oxygen circulation can be dated quite precisely to the year 1910” [EN 1]. Hermann Stelzner (1884-1942), engineer at Drägerwerke since 1906 and later chief engineer, designed the “Dräger- Submarine Diving Rescuer DM1”, as well as the “Dräger Diving Rescuer D2”. In the years that followed, he designed a series of further oxygen breathing apparatus for various applications above and under water. In 1915, for example, he developed the “bathing diver’s rescuer”, in 1928, the “counterlung”, from 1940 the “Dräger- small diving apparatus” and in the 1940s a new lightweight “Dräger diving rescuer”.

These small and lightweight constructions paved the way for autonomous Dräger diving equipment, which, in combination with flippers, allowed for extraordinary underwater mobility, in stark contrast to the previously used helmet diving equipment, which, due to its weight, could only be used within a limited radius from the deployment site.

None other than Hans Hass (1919-2013), an Austrian zoologist and marine researcher, significantly contributed to designing the first German small diving device. Together with Hermann Stelzner, he constructed in the spring of 1941 a new type of diving equipment from the “Dräger counter-lung” (see “Aegean 1942” in TH2 2014 by M. Müller), which he used from 1942 for over a decade in several exemplars for his expeditions, and later received the designation “Dräger 138 small diving device.”

The limited production of this small diving device suggests that this, like other Dräger devices, was used by the “sea fighters” of the German Navy at that time. However, no proving documents or indications for this are available to date. According to research, only “Dräger diving rescuers” and the “Dräger small diving device” from 1940 were tested for combat swimmer missions. The short duration of use of the devices was insufficient for these purposes. It is further reported that Alfred von Wurzian, an expedition companion of Hans Hass, also conducted experiments for a corresponding combat swimmer diving device in collaboration with Dräger. It is documented that submarine crews of the small combat units were equipped with Dräger submarine rescuers.

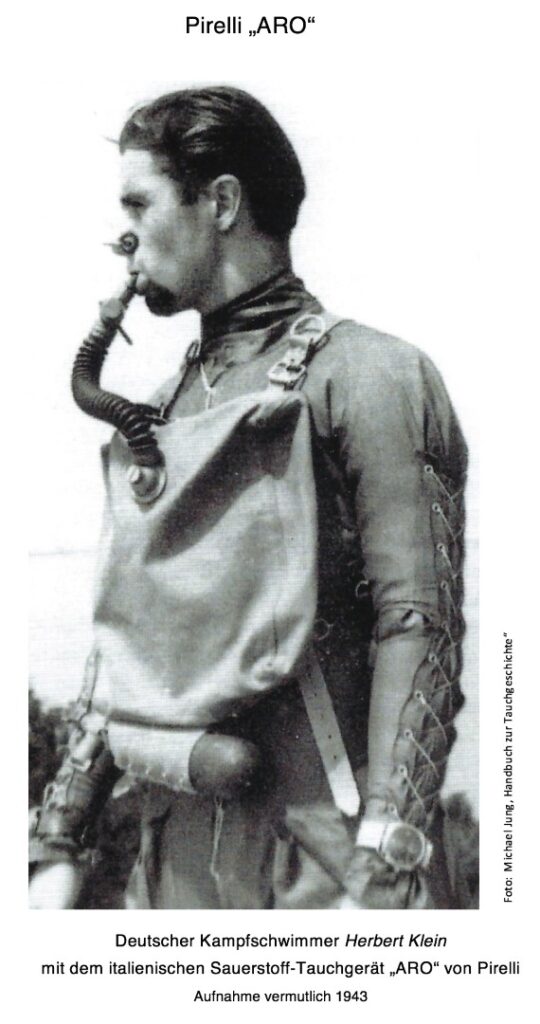

Since the combat swimmers of the Kriegsmarine received their training from the allied Italian “Gamma combat divers” at the training centre “Kloster San Giorgio on Alga in the Venice Lagoon” from the end of 1943, they were equipped with Italian Pirelli small diving devices (pendulum respirators)[Picture 8] from [EN2].

It was not until the end of the war that the German naval command recognized the value of combat swimmer missions. However, an increasing shortage of materials – even in the Dräger diving rescuer production – prevented the serial production of combat swimmer diving devices.

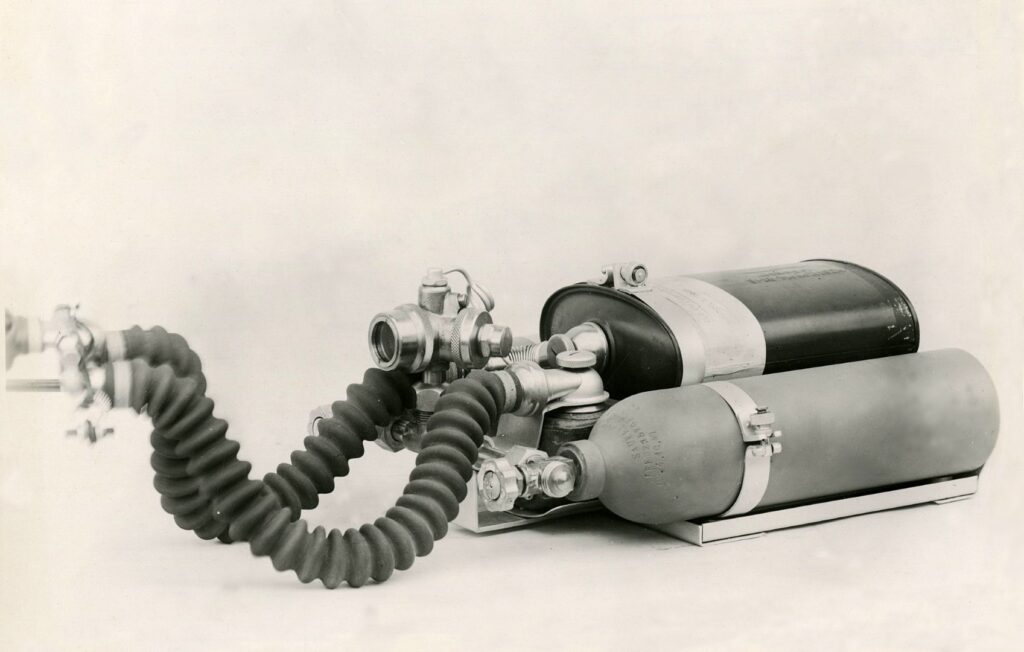

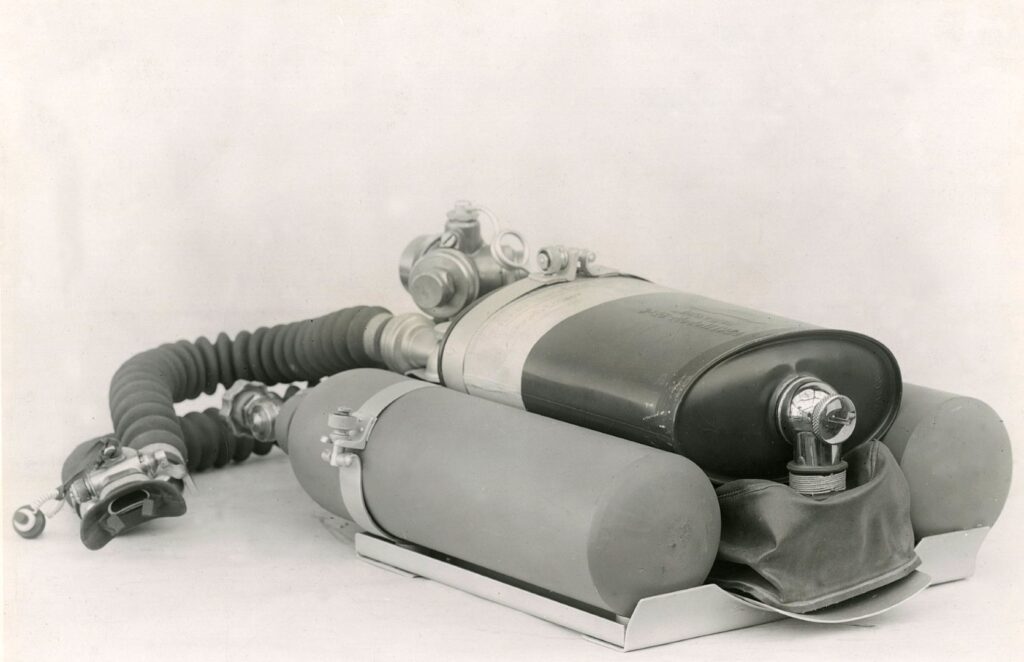

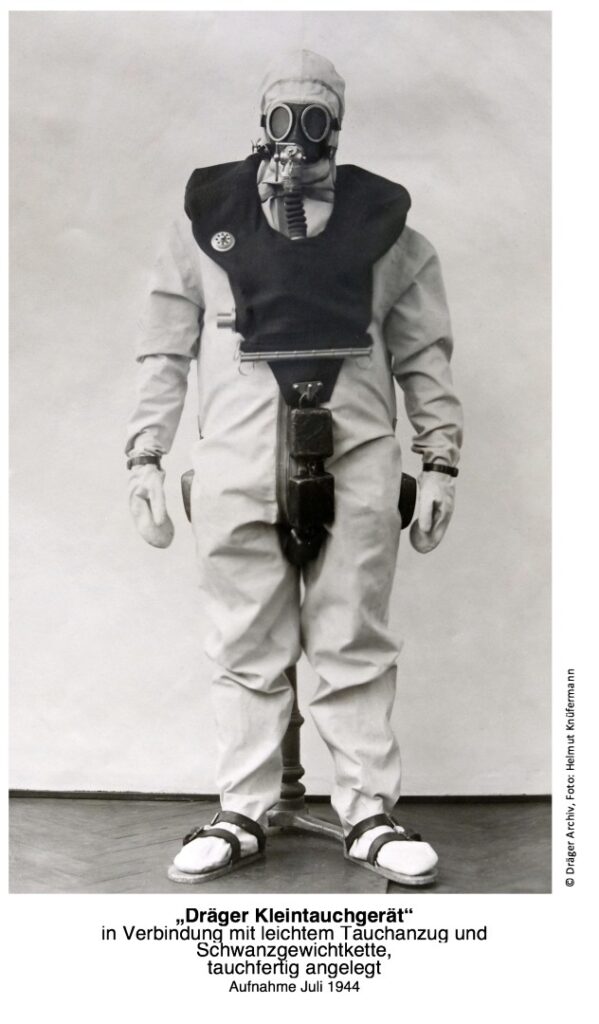

Nevertheless, during the war, Drägerwerke already had a finished diving device with a closed oxygen cycle “in the drawer,” in which Herrmann Stelzner was probably still significantly involved in the construction. However, production could no longer be started in the final stages of the war. [Picture 2 and 3] Design plans and drawings have not been found to this day. In the summer of 1945, a special department of the British occupation troops confiscated documents and devices from Drägerwerke and transported them to England[EN 3].It is not out of the question that parts of this expropriation are still in English archives today. Many products were immediately banned from production at that time due to their potential military usability, including diving devices. It would take until the early 1950s for Drägerwerke to officially return to manufacturing. military oxygen rebreathers for combat swimmers

More on this in the next instalment of this article.

Civilian Dräger oxygen diving apparatus before 1945

The Dräger Baderetter and Badetauchretter [EN4]

In 1913, the Drägerwerk created the “Baderetter”, based on the “Tauchretter” was developed at the Dräger factory. This oxygen diving apparatus was intended for use in water rescue. Technical documents are no longer available, so it is so that it is unclear to what extent it differs from the diving rescuer. All that is known is that the buoyancy was to be regulated with an inflatable buoyancy bag. The device should also enable strenuous work. The diving time was limited to 45 minutes, or 30 minutes at greater depths, limited. Two years later, the “bathing diver rescuer” was designed at the Drägerwerk was designed. Technically, it was largely similar to the “Dive Rescuer D2” [EN 5]. It did not have an additional compressed air cylinder (like the “Tauchretter DM2”). In 1926, the Drägerwerk launched an improved version of the bathing diver rescuer, the “Model 1926”, onto the market. The diving properties of this model were to be enhanced by additional iron sandals and a heavy neck chain.

The “Dräger-Gegenlunge TR”, small diving rescuer for use down to a depth of 15 metres [Picture 4]

In contrast to the models in the DM series and the bathing rescue device the counterlung is a pendulum breather. This means that there were no separate breathing hoses for inspiration and expiration. The diver breathes in from the breathing bag through an alkaline cartridge and a short piece of hose and exhales in the same way. The counterlung was a closed breathing apparatus.

The oxygen was topped up manually from a cylinder, which was located in the breathing bag and could be operated from the outside. The bottle size was 0.4 litres, and the maximum filling pressure was 150 bar. This meant that approx. 60 litres of oxygen were available. Through the lower opening, which was closed by a clamp rail, the oxygen cylinder and the alkaline cartridge could be replaced. The breathing air that expanded as the diver ascended escaped through a valve on the right side of the chest of the of the device. Further equipment included diving goggles, a nose clip and various weights. The “Dräger counterlung” was described by the manufacturer in the operating instructions however, due to its limited capacity for light underwater work.

The “Dräger -Kleintauchgerät” for light diving work

The small diving apparatus [Fig. 5], also a pendulum breathing apparatus, was a further development of the ‘Gegenlunge’, intended for light underwater and also intended for water rescue. intended for water rescue. In a catalogue from 1933, this version of the counterlung version of the counterlung with a larger alkaline cartridge and a larger oxygen cylinder of 0.6 litres instead of 0.4 litres. The small diving apparatus was first advertised in 1940. The modified device is similar to the aforementioned form of the counterlung. Here, too, the oxygen was refilled manually from a bottle. Due to an enlarged alkaline cartridge and oxygen cylinder, the diving time was 35 minutes for light work or one hour at rest to a depth of 13 metres. The small diving device weighed without weight chain approx. 3.5 kg.

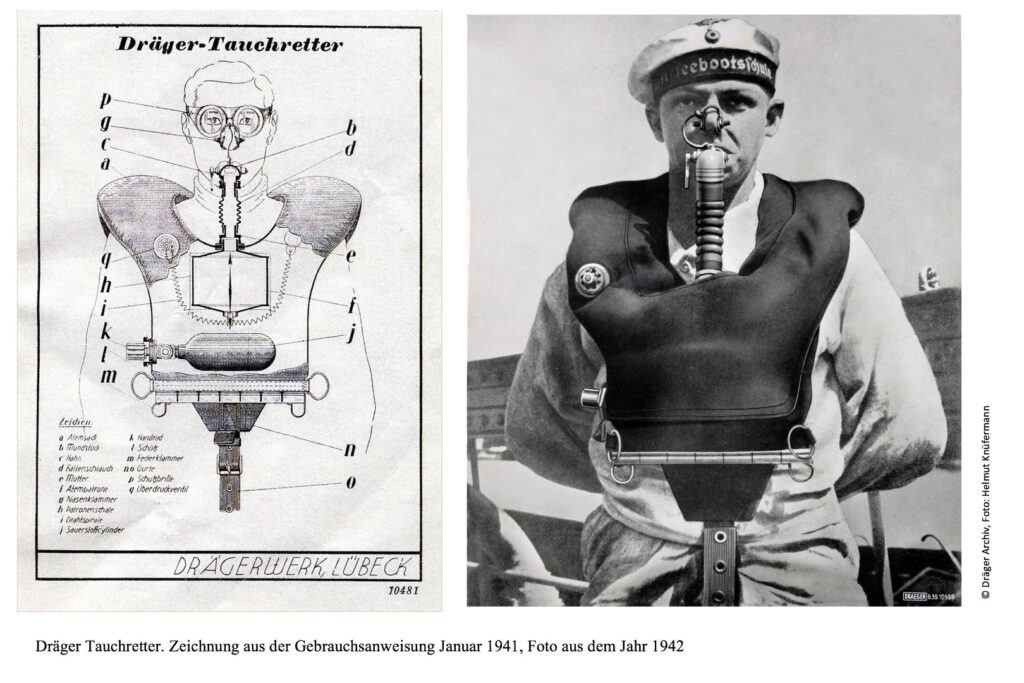

The “Dräger-Tauchretter” “submarine escape unit”, Mod. 1944

This diving rescuer [Figures 6 and 7] from the year of production 1944 also corresponded technically to the design principle of the counterlung and small diving apparatus described above. This pendulum breathing apparatus was used for exiting from sunken submarines down to a depth of 100 metres. The Breathing from the diving rescuer only took place shortly before the submersion, to avoid harmful oxygen exposure in the event of high air pressure exposure to oxygen. Chlorine gases in the boat….

Image 7: Drawing from the instruction manual January 1941 © Dräger Archive, Photo: HK (left)

required immediate use. For surfacing from depths of 30 to 100 meters, the breathing bag should be filled with about three breaths of air and the rest with oxygen. During an unforeseen prolonged stay in the boat or a longer ascent, it was necessary to refill oxygen every 5 to 10 minutes. The alkali cartridge and oxygen supply were sufficient for about half an hour.

The expanding breathing gas in the breathing bag during the ascent escaped through the overpressure valve and should also be released at the corners of the mouth. This diving rescue device was also used as a water rescue device, gas protection device, and in emergencies as a breathing apparatus for firefighting.

Use and Construction of Military Oxygen Recycling Devices

During World War II, some nations with their combat diver special units had already proven that targeted acts of sabotage could thwart the enemy’s planning and execution.

Lieutenant Commander Herbert Völsch stated [EN 6 ]: “There are hardly more effective methods to weaken opponents unnoticed than the silent and bubble-free intervention by combat swimmers underwater. These methods differ with their cunning, camouflage, and surprise from the ‘classic open engagement’ through ‘asymmetric warfare’.”

“An advantage of ‘asymmetric warfare” lies in the ratio of low effort to effective benefit. Experience has shown that a combat swimmer team is capable of immobilizing a heavily armed military unit with simple means. “Tactical combat swimmer operations require the use of oxygen recycling diving devices that significantly differ from civilian versions and are specifically designed for this need:

– Silent operation

– Non-magnetic design

– Closed, bubble-free recycling principle

– Cold-resistant

– Blind handling capability, glove-friendly

– Quick donning and doffing of the device

– Uncomplicated technical structure

– Military robustness

– Reliable and quick readiness for use

– Smallest possible size for maximum duration of use

– Light weight

– Unobtrusive colouring

The combat swimmer devices from companies like Siebe & Gorman, Mommsen, Lambertsen, Dunlop, and Pirelli, among others, more or less fulfilled these characteristics during the world war. Most devices were worn with a breathing bag and oxygen bottle on the chest and were pendulum breathers (see [Image 8] “Pirelli ARO”). The oxygen supply was provided by manually opening the bottle valve. The mouthpiece had a simple shut-off valve, and the lime container was usually located in the breathing bag. There was no manometer to determine the bottle pressure (no more oxygen = surface) – simple constructions.

Generally familiar, but for a better understanding of the devices described below, the principle of closed oxygen circulation devices: The breathing system – Pendulum breathing system, in which a single breathing tube is used to inhaled and exhaled via a single breathing tube. After 1945, oxygen rebreathers for military use are increasingly by more advanced circulation systems replaced. – Circulation system with a real circuit. Inhalation and exhalation hose are separate, and the direction of the breathing gas flow is determined by control valves.

The oxygen supply

In principle, oxygen can be supplied to the respiratory circuit in three different ways:

– manual supply, no longer used for military devices (such as the Pirelli ARO from 1943 [Fig. 8])

– constant dosing, devices with continuously adjusted (usually 0.8 – 1.2 l/min) (all devices in parts 1 and 2 of this of part 1 and 2 of this article)

– automatic lung dosing, automatic lung devices, in which oxygen is automatically added as the volume of the breathing bag (type: LAR, all devices in devices in part 3 of this article) Both of the latter device types can be equipped with a manual add-on valve with which spontaneous administration of oxygen can be of additional oxygen is possible.

Dräger oxygen rebreathers for military operations after 1945

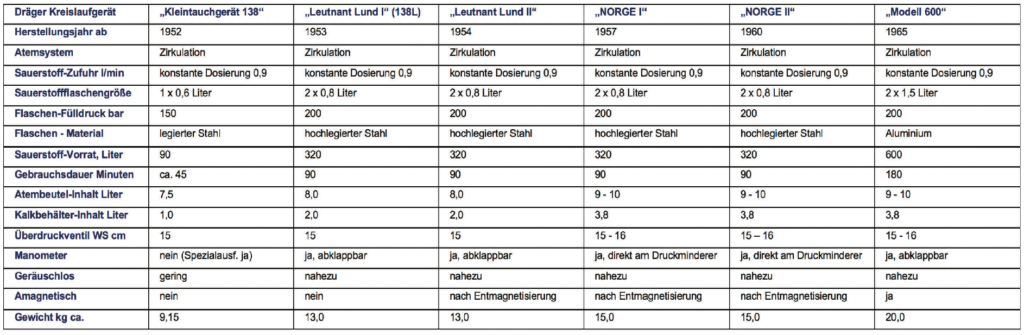

The “Dräger small diving apparatus 138” (Dräger drawing no.: T3200)

As described, Dräger already manufactured an oxygen small diving device for Hans Hass in 1942 [EN 7]. Together with chief engineer Hermann Stelzner, he designed a new small diving device from the “counter-lung” in 1941. The main changes involved relocating the carrying position of the breathing bag from the chest to the back, a continuous oxygen supply to the breathing bag with an additional oxygen dosing valve, and converting the pendulum breather into a closed-circuit rebreather, where inhalation and exhalation took place through two separate corrugated hoses.

Many trials, modifications, and patent applications were carried out until it was satisfactorily usable. A patent from the final war years included another improvement of the breathing bag, which was only recognized in 1951 due to the takeover of government authority by the Allies in 1945 and the associated consequences and barriers.

This oxygen closed-circuit device later received the designation “Dräger-Kleintauchgerät 138” and was officially marketed by Dräger from 1952. According to unverified information, Dräger delivered a few units to the “United States Navy” for military use even before 1951 [EN 8]. Devices for this application fell under the War Weapons Control Act at the time. It is likely that the Allies managed to bypass this in secrecy. The records have been destroyed.

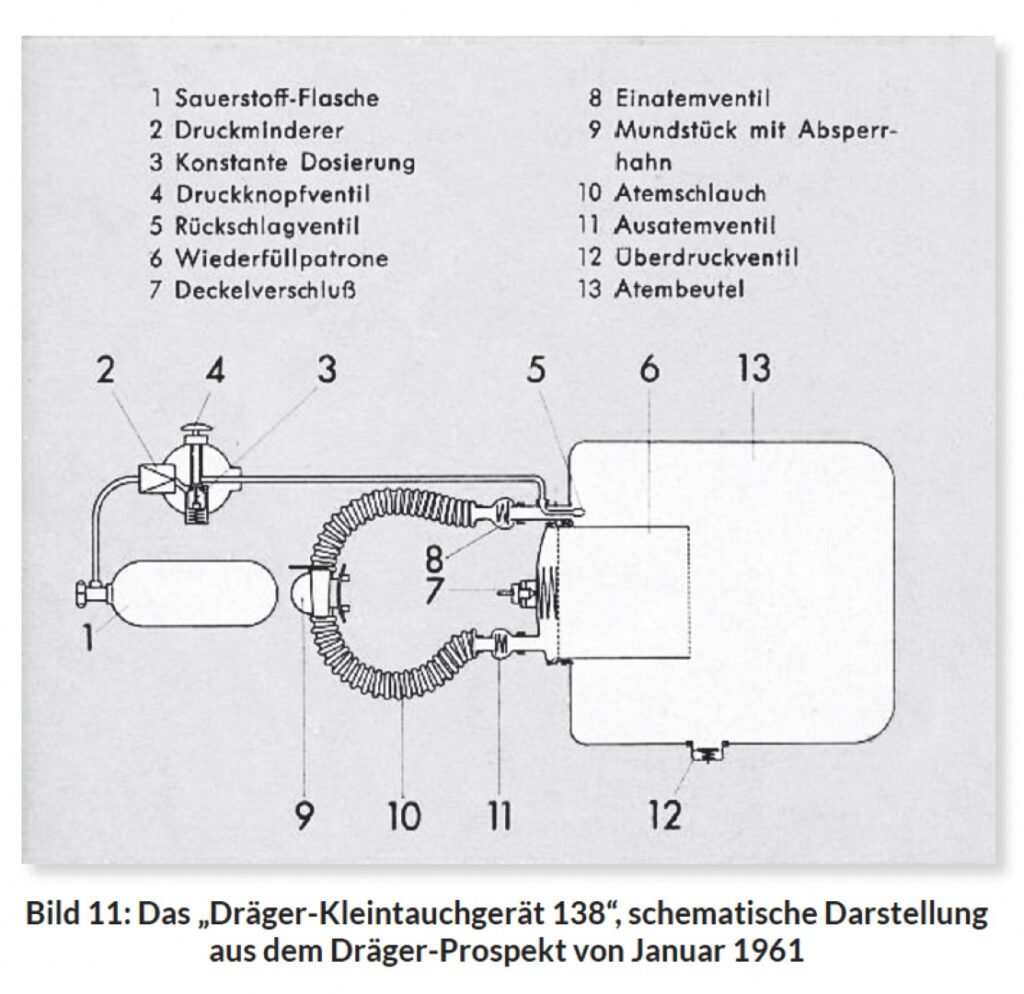

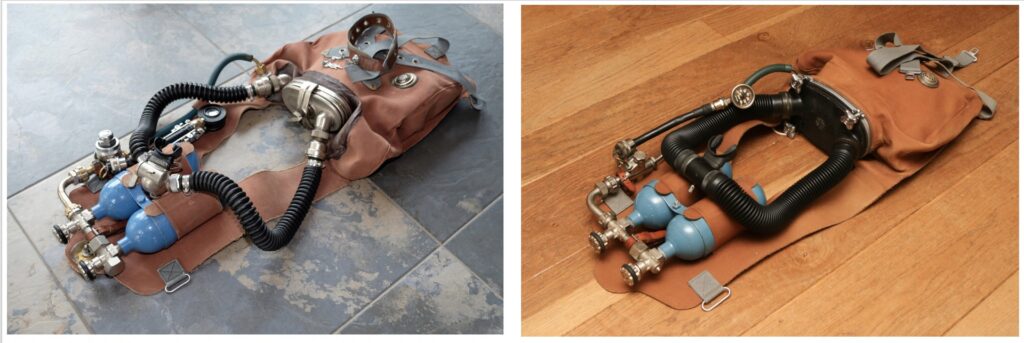

The technical construction of the “Dräger 138” was essentially completed in 1952. The back part of the vest, made of rubberized reddish-brown textile fabric, had an integrated breathing bag. The vest carried the 0.6-liter oxygen bottle with a filling pressure of 150 bar on the chest part. Additionally, there was a pocket on the chest part for additional lead weights for buoyancy control. Unlike pendulum breathers, inhalation and exhalation here took place through separate corrugated hoses with integrated valves. Thus, the breathing gas in the circuit travelled through the 1-liter soda lime refilling container and the approximately 7.5-liter breathing bag [Image 11].

The inhalation and exhalation valves were not directly at the mouthpiece but at the device-side hose connections. The mouthpiece [Image 29 Part 2] had a built-in shut-off valve to block the breathing circuit from ambient air when not in use. A loop on the mouthpiece held the nasal clip, whose use was mandatory at the time.

The operating manual G 221 from 1956 contained the following note, which could hardly be ignored even with effort: “If the breathing bag does not fill when pressing the oxygen add-on valve button, the oxygen supply is depleted. Then you must surface immediately.”

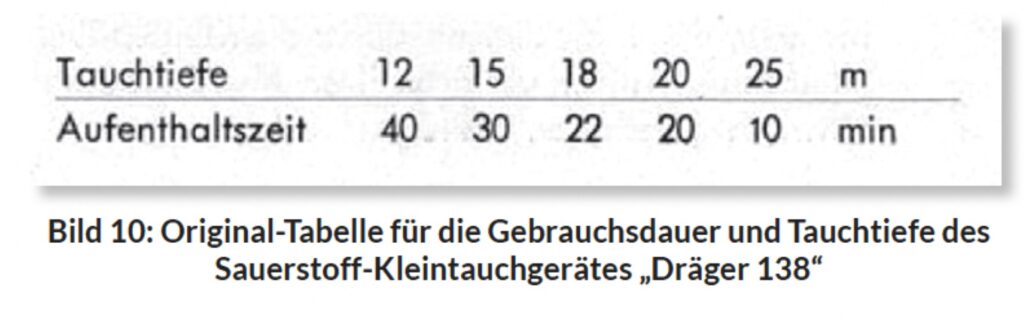

The standard version of the “Kleintauchgerätes Dräger 138” did not include a pressure gauge for checking cylinder pressure, which would have been desirable for more frequent and professional use of the device. So, it is not surprising it is therefore not surprising that Hans Hass was already was equipped with “Dräger 138” predecessors for his expeditions, which contained a pressure reducer with pressure gauge. The pressure regulator described in the Dräger instruction manual 65-G 11/G from 1952 (1st edition) for the “Dräger 138” were for the depth of use and dwell time referred to “low physical referred to “low physical work at an oxygen concentration of approx. 85 concentration in the breathing bag – after correct breathing and filling with pure oxygen”. Even if the instructions for use clearly point out the dangers of oxygen deficiency and oxygen poisoning, the usage data in the usage data in the Dräger table of the original instructions for use appear daring according to current knowledge [Fig. 10]. However, none other than Hans Hass himself, to whom the construction of this rebreather is due to no less a person than dived to depths of more than 25 metres.

Dräger continued to manufacture the “Dräger 138 small diving apparatus” until the mid-1950s and also marketed it as a recreational as a scuba diving device via the company “Barakuda” in Hamburg. The selling price at that time was DM 490. Even before 1951, the “138” was already being sold to various western naval units. Among others, the “United States Navy” for use in the Korean War (1950-1953) ordered a number of examples. Not through direct delivery, but via detours the “Dräger 138 small diving apparatus” also reached eastern.

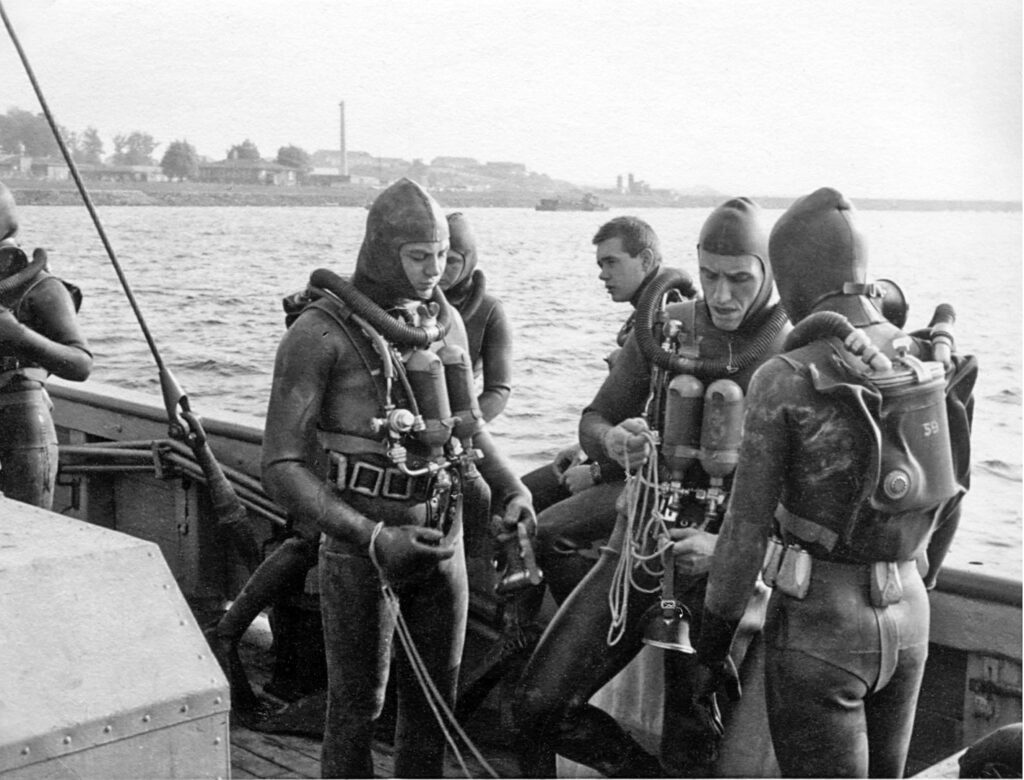

From 1948, the Yugoslav army received U.S. military aid until the 1950s. As a result, they had a mixture of originally Soviet, American, and increasingly self-produced weapons systems and equipment for decades. Some of the “Dräger small diving devices 138” purchased by the US Navy (UDT) in 1951 for use in the Korean War also found their way to the Yugoslav People’s Army through military aid [Image 13].

As a founding member of NATO in 1949, the Norwegian Navy had a particular interest in securing its coastlines and introducing special forces. The successes of Italian and English underwater saboteurs in World War II were the focus of the “E-Service” division of the “Sjøforvarets Overkommando” (Naval High Command). Thus, from July 1952 to May 1953, Ove Lund, a Norwegian naval officer, received “frogman training” at the “SOK / A III E.” (Navy Command) in the USA. He trained there with the “Dräger 138”.

In December 1952 (during his Christmas vacation at home), Lund met personally with Heinrich Dräger at the Dräger works in Lübeck [EN 9], bringing the concept of the “SOK E-Service” for planning a Norwegian Navy frogman school and the task of procuring the necessary equipment. Based on his experience with the Dräger closed-circuit device at the US Navy, the decision for a “Dräger device” was made for the “Dräger small diving device 138” [Image 12] was a natural choice. Initially, they agreed on a first delivery of a few devices. Although no records exist of the delivered quantities, the use of these devices at the start of the frogman school is documented in the graphical representation of the “SJØ-FORSVARETS DYKKER- OG FROSKEMANNSSKOLEN”.

In March 1953, Lund (by then “Lieutenant”) worked with the first instructors in Oslo, Ørnulf Theodorsen, and other trainers to develop a strategy according to his ideas. That same summer, the first test of Norwegian applicants took place on the Bolærne island group in the Oslofjord. 8 out of 24 applicants were selected. The students came from the navy and the coastal artillery. The frogman school used the newly delivered “Dräger 138 closed-circuit devices” during the course of 1953.

However, early experiences soon showed that the “Dräger 138” was insufficient for this purpose. A manometer was missing.

The professional manoeuvrers of the “Froskemenn” students led to significantly higher oxygen consumption than previously experienced in the civilian sector. Continuous monitoring of the remaining oxygen during operations was essential. Thus, the Norwegian frogman school quickly received special versions of the “Dräger 138” with a “foldable” manometer [Image 14][EN10].

This manometer was located at the end of a high-pressure hose, connected to the pressure reducer, in a foldable lockable bracket, which could also be easily read underwater and had luminous figures. The externally guided manometer extension was also used on Dräger compressed air devices at that time. Whether the already delivered “138s” were subsequently retrofitted with manometers or new units with manometers were ordered is not documented.

Endnotes

EN 1 Michael Jung, ” Handbuch zur Tauchgeschichte” Nagelschmid-Verlag, Stuttgart, 1999

EN 2 Michael Seydel, ” Die Entwicklungs- und Nutzungsgeschichte der Tauchretter des Drägerwerkes” 20. 8.2.3: “Strongly influenced by the Italians, the German combat swimmers also used Italian diving equipment. It is unknown why Dräger’s devices were not utilized.”

EN 3 “COMBINED INTELLIGENCE OBJECTIVES SUB-COMMITTEE” G-2 Division, SHAKF (Rear), APO 415

EN 4 Michael Seydel, ” Die Entwicklungs- und Nutzungsgeschichte der Tauchretter des Drägerwerkes ” 2010

EN 5 ” Tauchretter Dräger D2″ a special design for the Danish Navy

EN 6 Paraphrased quote from Lieutenant Commander Herbert Völsch, combat swimmer of WWII and first training director of the Bundesmarine’s combat swimmer company, co-founder of VDST and DUC Krefeld, whom I met at age 17 as a member of DUC Krefeld (member No. 13) in 1963 and who brought me to the Bundesmarine: “Boy, come to the Navy, there you can dive!”

EN 7 Michael Jung ” Das Handbuch zur Tauchgeschichte ” Stephanie Naglschmidt Publishing Stuttgart 1999

EN 8 Archive, National UDT Navy Seal Museum, 3300 N Hwy A1A, Fort Pierce, FL 34949, USA

EN 9 Dräger Document Archive, meeting note from 12.12.1952

EN 10 Dräger Image and Document Archive

Conversations and Correspondence

- Achtert, W., former combat swimmer of the Bundesmarine

- Birkeland, E., former “Sjef for norsk marinens Dykkerog Froskemannskole” Norway

- Haux, G., personal conversations of recent years

- Höner, J., combat swimmer of the German Navy

- Jørgensen, S.-E., Danish Society for Historical Diving, diving historian

- Kahrs, B.W., former instructor at “Comex Diving” and diving historian

- Müller, K., former mine diver of the Bundesmarine

- Phalén, W., former combat swimmer of the Swedish “Kustjägarna”

- Sartor, W., former development engineer at Drägerwerke

- Sassen, U.W., former combat swimmer of the Bundesmarine

Literatur

• Boczek, W., Hilbert, J.: „Tauchen mit Sauerstoff-Kreislaufgeräten“, Delius Klasing, 2008

• Donald, K.: „Oxygen and the Diver“, SPA limited, Britian, 1992

• Ehm, O. F. et al.: „Tauchen noch sicherer“, Müller Rüschlikon, 2003

• Haux, G.: „Typisch Haux“, Haux Publishing, 2002

• Haux, G.: „Tauchtechnik“ Band I + II, Springer-Verlag 1969

• Hesselmann, H.: „Sabotage unter Wasser“, Zeitschrift Delphin, 12/68 – 09/69

• Jørgensen, S.-E.: „Udvikling af iltapparatet (kredsløbsapparatet)“

• Jung, M.: „Handbuch zur Tauchgeschichte“, Naglschmid, Stuttgart, 1999

• Jung, M.: „Sabotage unter Wasser“, Mittler & Sohn, Hamburg, 2004

• Kahrs, B.W.: „NORSK DYKKING“, Kolofon Forlag, 2014

• Krange, E.: „FRA MARINEDYKKINGENS HISTORIE I NORGE“, Erkra Forlag Kristiansand, 1994

• Seydel, M.: „Die Entwicklungs- und Nutzungsgeschichte derTauchretter des Drägerwerkes“, 2010, Müller, M.: „Ägäis 1942“ (1. Kreislaufgerät von HH) TH2 2014 S. 13

• Stelzner, H.: „Gegenlunge und Badetauchretter“, Dräger-Hefte, Nr. 139, Juli 1929

• Stelzner, H.: „Tauchertechnik“, Verlag Charles Coleman Lübeck,1943

• Ulmer W.T.: „Die Lungenfunktion. Methodik und klinische Anwendung“ 2003, Thieme ISBN 313448806X

Notes

- Federal Archives (Military Archive), Freiburg

- Federal Office for Military Technology and Procurement, Koblenz

- Drägerwerk: various user manuals for Dräger oxygen breathing devices, Lübeck

- Drägerwerk: image, document, and device archive, Lübeck

- Combat Swimmer Company, Eckernförde

- Command of the Naval Weapons, Kiel

Page 1 of Part 2 of 4

space 1

space 2

space 3

space 4

PART 2

Dräger Diving Devices for “Combat swimmers”

Chronological development of closed-circuit oxygen scuba diving equipment from the Dräger factory for military use

By Helmut Knüfermann

Part 2 of 4, Devices in “Vest” design type 2

Oxygen Diving Apparatus “Leutnant Lund I” (Dräger-Kleintauchgerät Model 138L)

It was foreseeable that the operations with the initially used “Dräger Small Diving Devices Model 138” could not be satisfactory for military operations in the long run. Therefore, new developments took place. At the end of 1953, Lieutenant Lund, together with chief engineer Hermann Tietze at Drägerwerk in Lübeck, designed an improved oxygen closed-circuit device according to his specifications.

The primary requirement was a longer operational duration. This new oxygen closed-circuit diving device, initially referred to by Drägerwerk as the “Dräger Small Diving Device 138 L” (Lund), eventually received the official designation “Leutnant Lund I”.

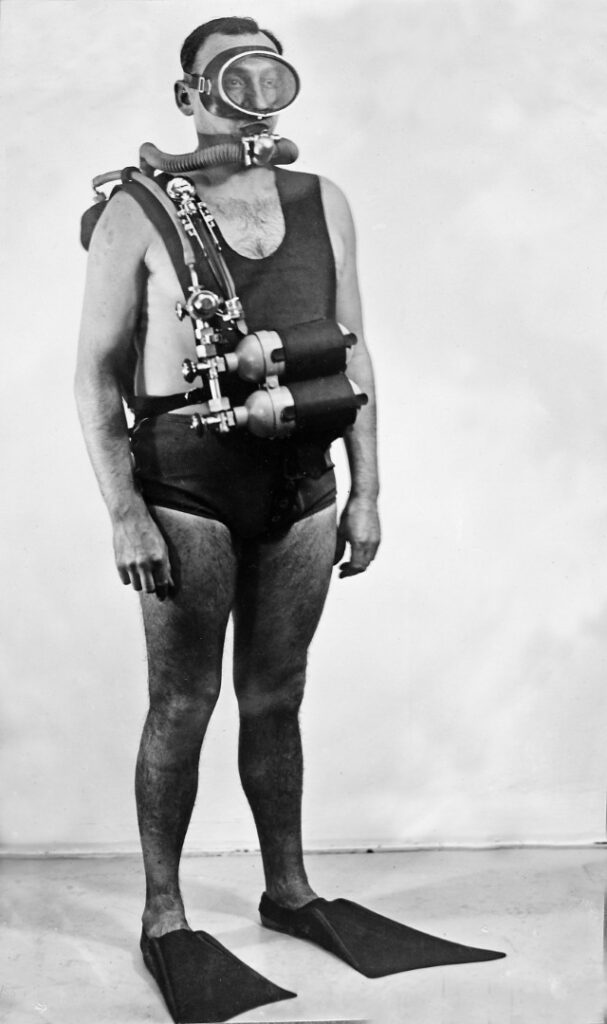

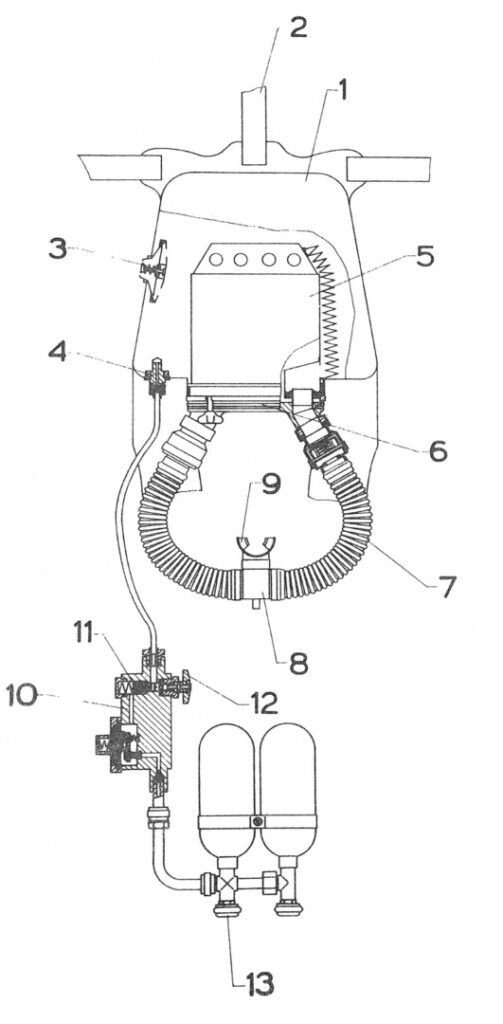

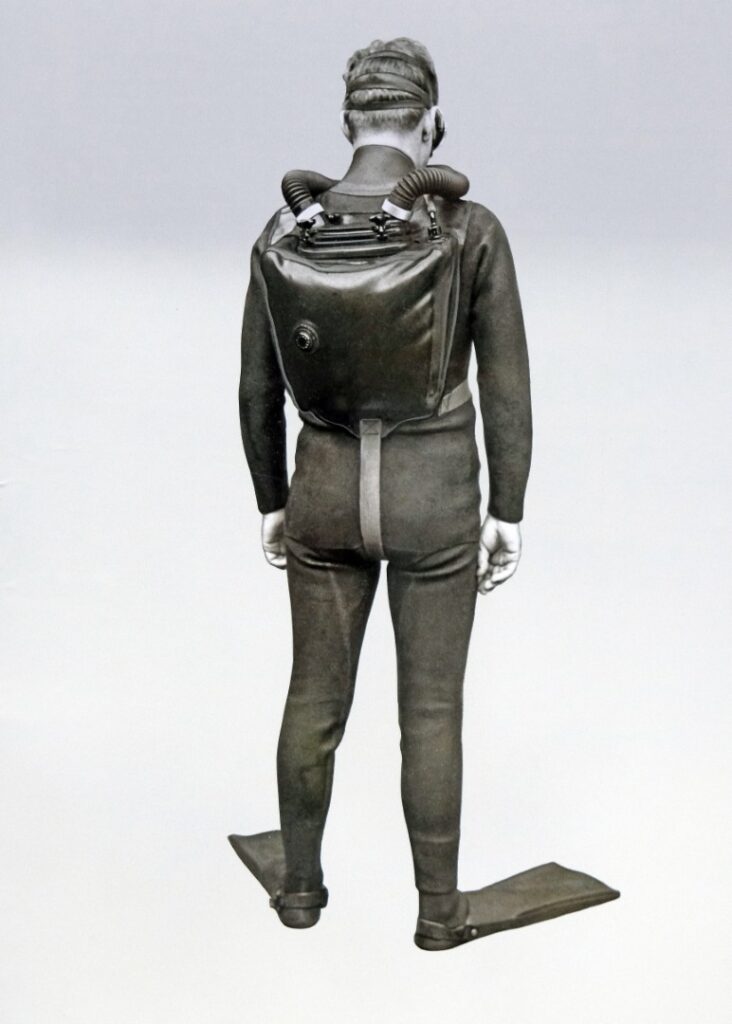

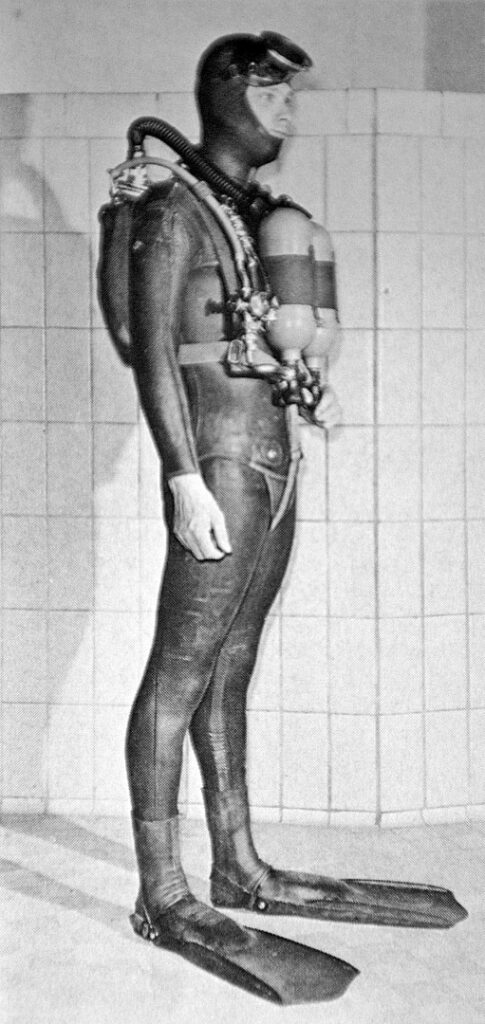

The description below is detailed, as the “Leutnant Lund I” served as the basis for the subsequently described closed-circuit diving devices in “vest” construction. With the “Leutnant Lund I” [Image 15], a device was created in the same construction as the “Dräger Small Diving Device 138,” but with two horizontally arranged oxygen bottles on the chest panel, each containing 0.8 liters, instead of one bottle with 0.6 liters as previously. With an increased filling pressure of 200 bar, the diver now had 320 liters of oxygen available instead of 90 liters.

As the supply of breathing gas is not the only factor limiting the use time of closed-circuit oxygen devices, but also the amount and CO2 absorption capacity of the soda lime, the soda lime container also received a larger filling volume from one to two liters. The maximum dive time was now approximately 90 minutes, with an average oxygen consumption of up to 2 l/min easily covered.

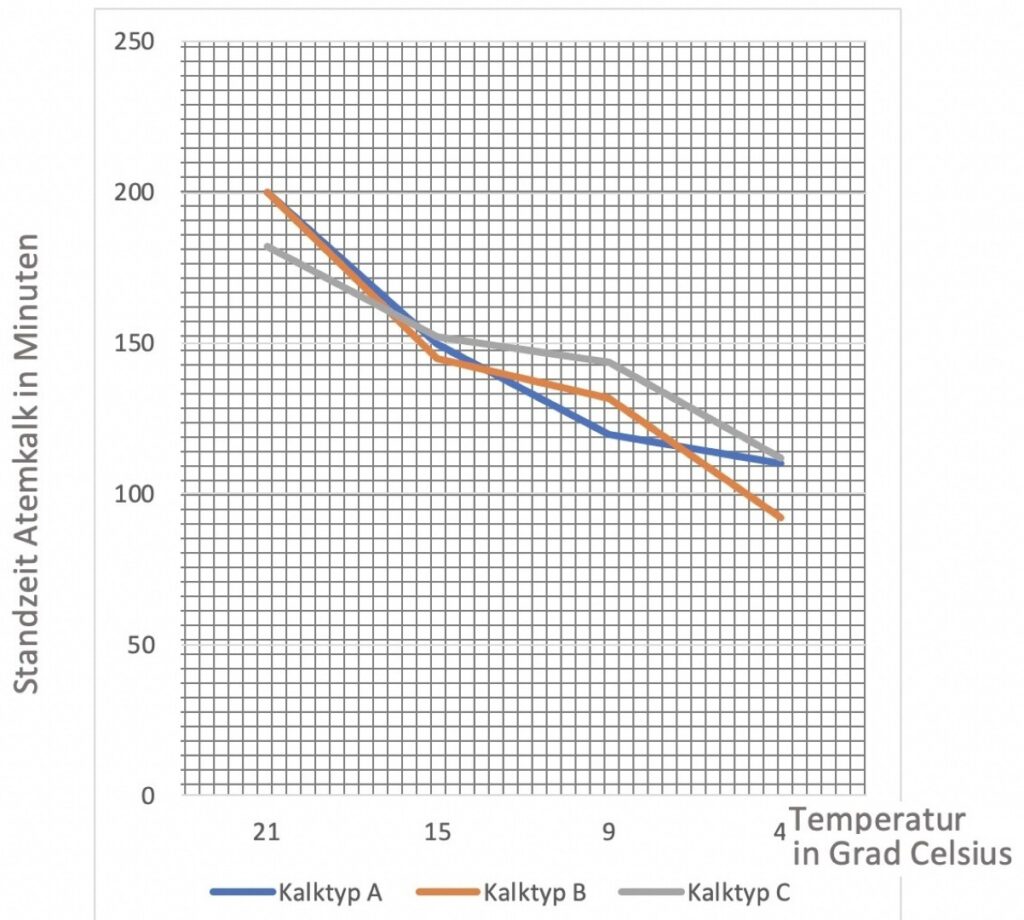

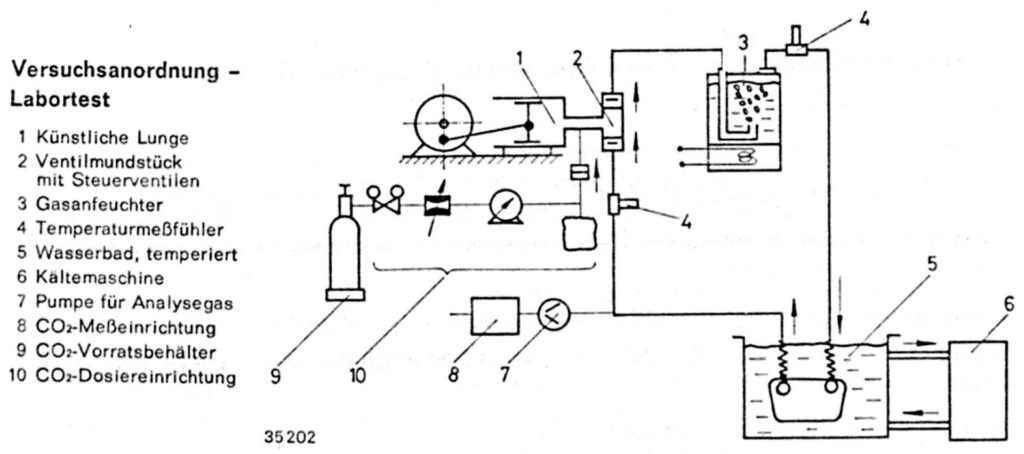

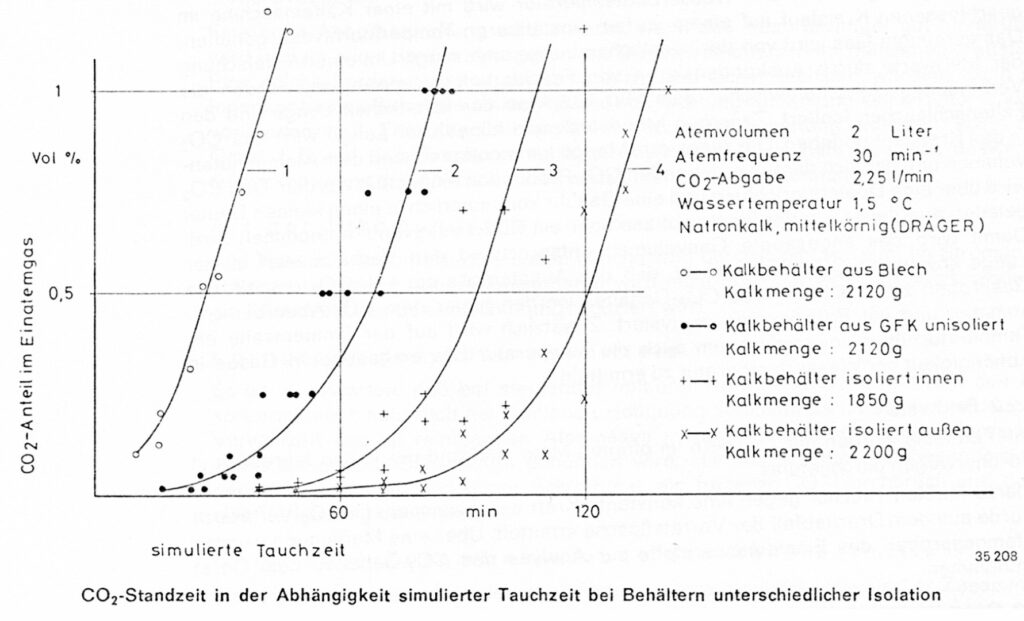

The position of the oval soda lime container in the breathing bag itself had the advantage, as with almost all closed-circuit oxygen devices in “vest” construction, that the soda lime retained good CO2-binding capacity in the ambient warmth of the exhaled air even at low water temperatures.

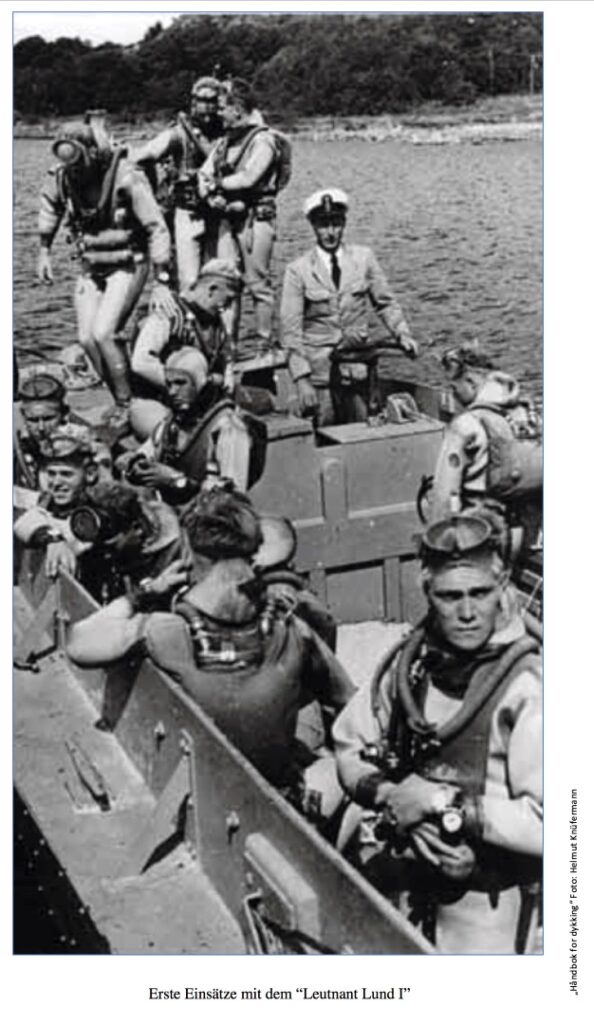

Picture 15: First missions with the “Leutnant Lund I” in 1953. Source: “Håndbok for Dykking I Navy, KNM Tordenskjold,Dykker- og froskemannsenteret”

In hard-shell devices of later generations, where the soda lime container is installed separately and directly surrounded by ambient water, separate insulation helps prevent cooling, which can reduce the service life of the soda lime by more than half at temperatures around 4 °C and below. As pure oxygen was used as breathing gas, the operating depth—like with all closed-circuit devices—was theoretically limited to about 7 meters due to oxygen toxicity at an O2 partial pressure of 1.6 bar, but practically to 10 meters (due to never having 100% O2 concentration in the breathing bag).

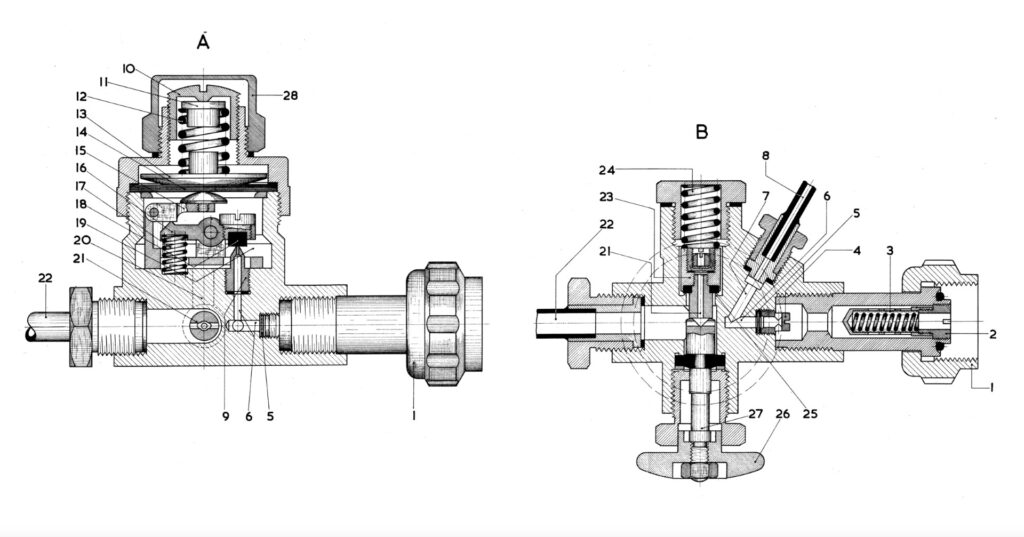

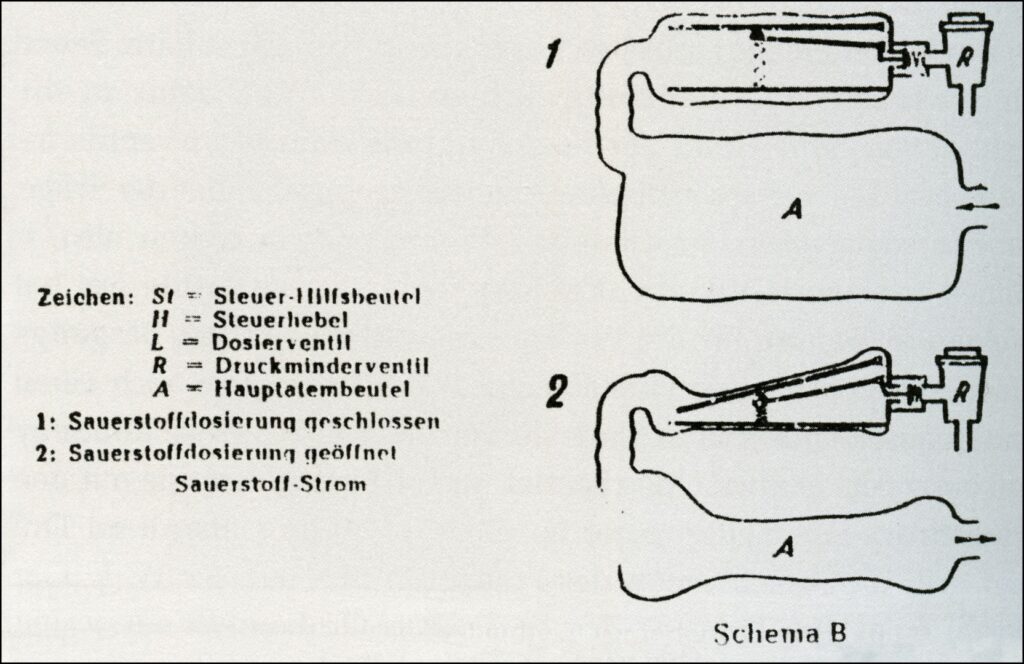

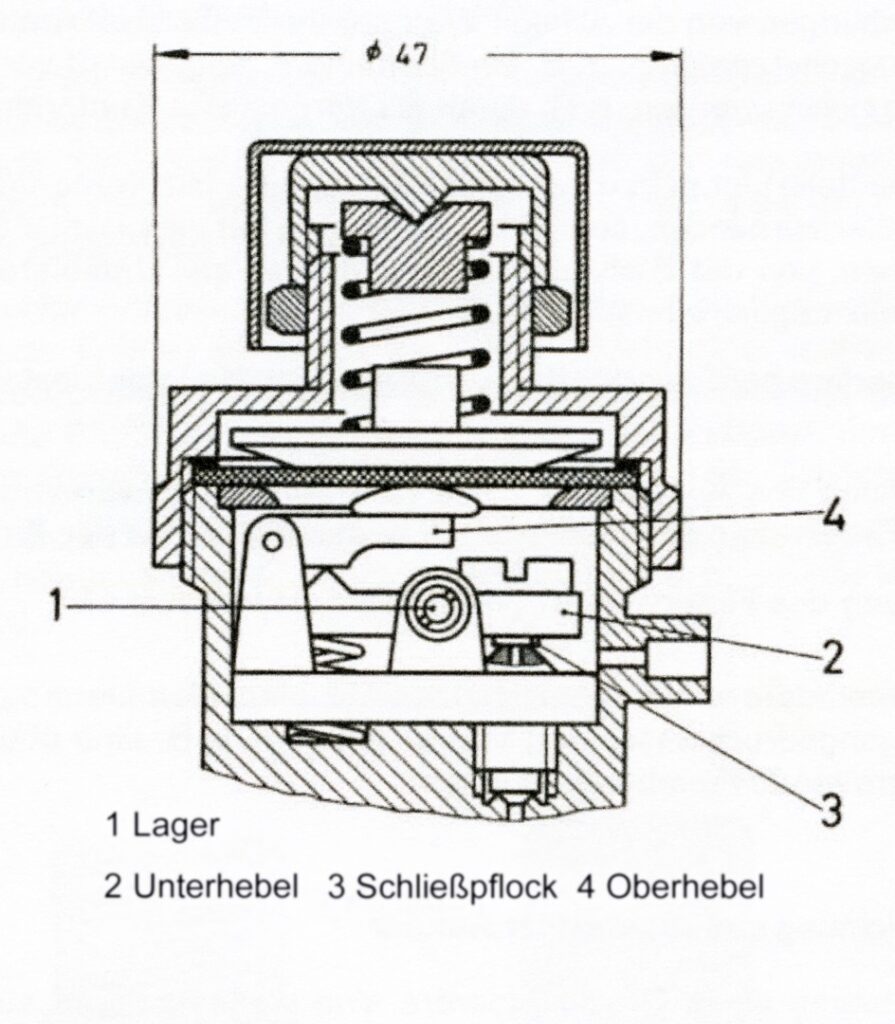

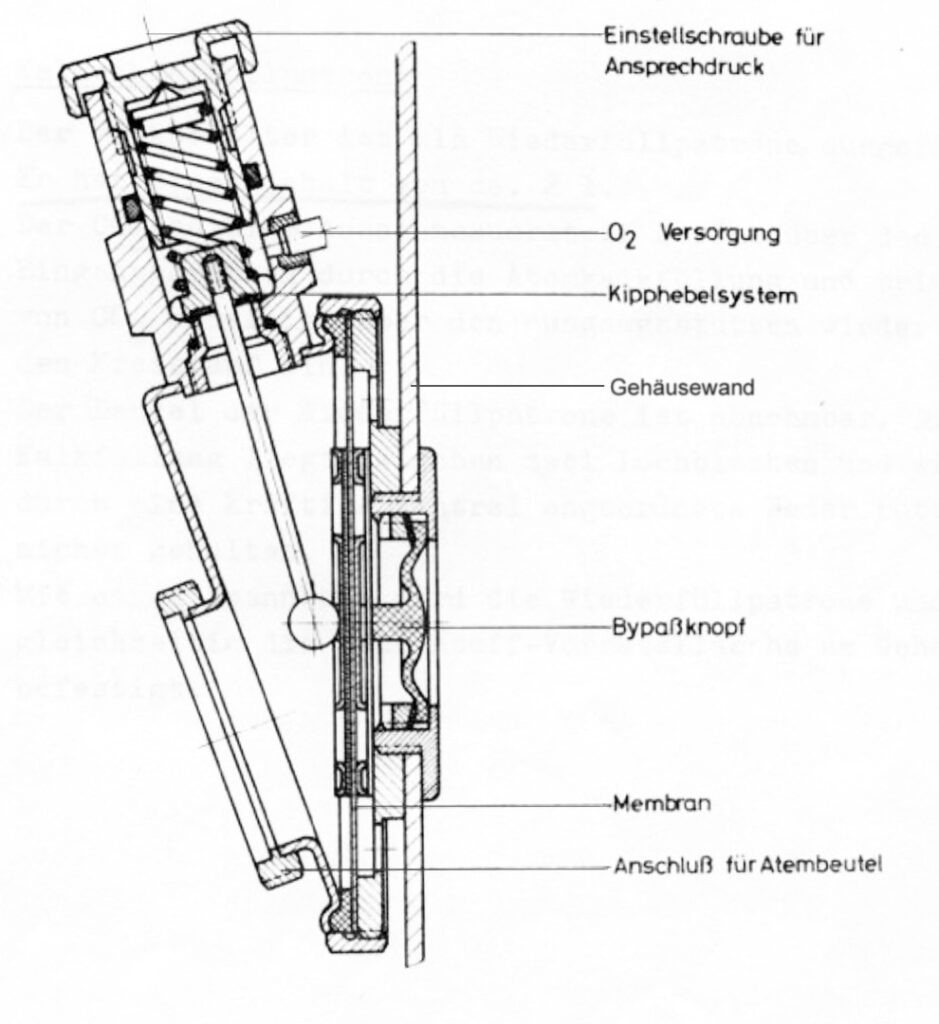

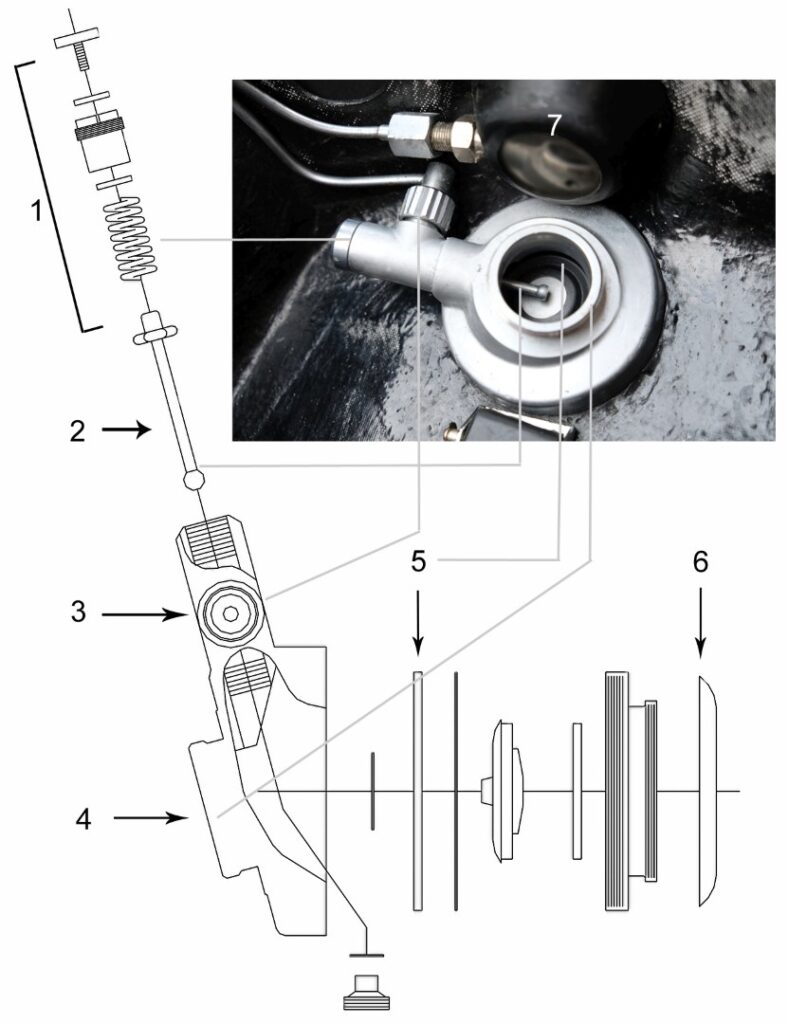

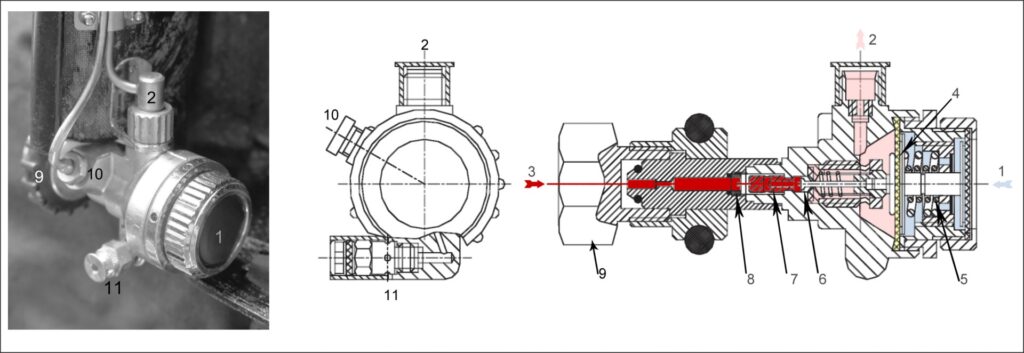

The pressure reducer of the same design as for the “Dräger 138” also had a constant dosing set to 0.9 l/min, which could also be spontaneously increased with a larger oxygen flow through the integrated hand-addition valve. This functionality kept the oxygen amount constant over the entire bottle pressure and diving depth range. This pressure reducer, which Drägerwerk built in the same and slightly modified construction for various breathing devices, is also found in the oxygen closed-circuit diving devices in “vest” construction described in this article. The technical drawing [Image 17] and functional description therefore apply equally to all these mentioned devices.

Function of the Pressure Reducer of Dräger Oxygen Closed-Circuit Diving Devices in “Vest” Construction:

The pressure reducer is connected to the oxygen bottle (1) with a G3/4″ union nut. A nozzle (2) holds and centers a very fine rod filter (3). Through this transition to the further nozzle (4), the oxygen passes through a 3-layer membrane (5), which retains the smallest impurities to the channel (6). From here, a branch channel (7) leads to the manometer hose (8). The channel (6) continues in an angled bore (9) to adjust the medium pressure reducing valve.

The medium pressure of the reducing valve can be adjusted by setting the sealed ring-slot screw above (18). From there, the gas reaches the pressure piston (11) with the spring (12), the pressure disc (13), and the membrane (14), which regulates a continuous oxygen supply of 0.9 l/min and can be adjusted through the slot in the union nut (10).

Through the pressure cap (15), the membrane (14) swivels into its resting position. The valve (16) causes the reducing valve (18) to lift and allows the oxygen from the channel (6) to flow into the cavity (19). Once the pressure rises to about 4.5 bar, the oxygen pressure on the membrane (14) increases, overcoming the counterpressure of the spring (12) and the closing spring (17), and can now move the valve (18) to close the oxygen supply.

The oxygen addition is triggered by manually pressing the button (26), which releases the cone valve (21) against the spring (24) for the duration of the press through the pressure piston (27), allowing an oxygen flow from the medium pressure area (19) with a flow rate of about 14 l/min.

A in [Image 17] shows a vertical section through the pressure reducer and B a horizontal section with a dosing nozzle and the “hand addition valve”. Just like the pressure reducer [Image 18] (here with manometer connection), the mouthpiece with shut-off valve was also adopted from the “Dräger Small Diving Device 138”, as well as the inhalation and exhalation valves, the overpressure valve in the breathing bag, and the foldable manometer for controlling the bottle pressure during diving.

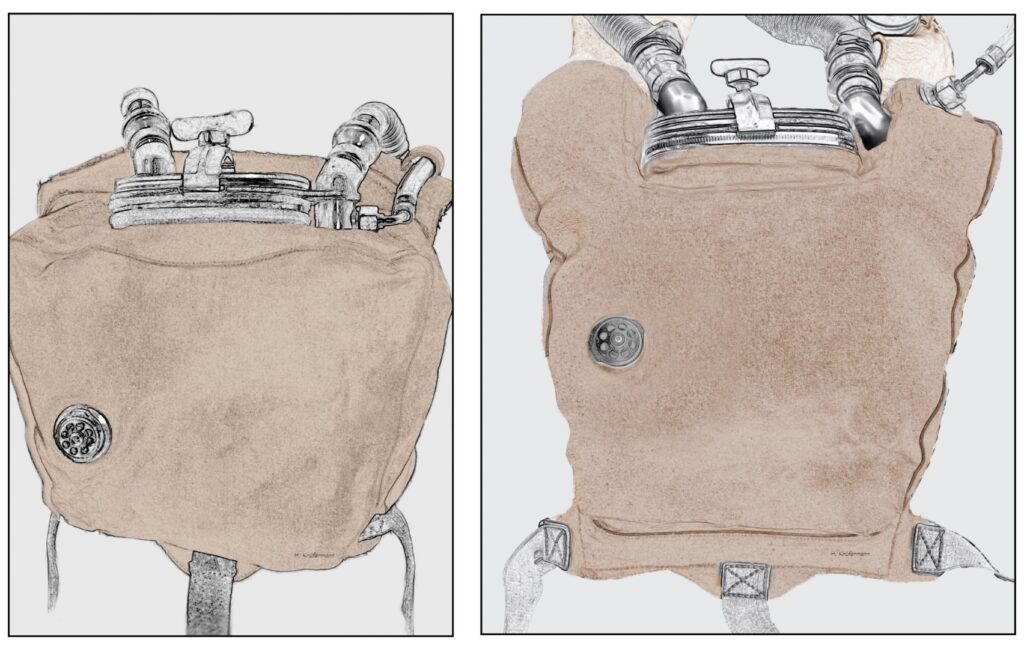

The breathing bag on the back received a new shape compared to the “Dräger 138” with two bulges on the right and left above the soda lime container access [Image 19]. The snug fit on the body and the favourable shape, especially the bulges at the shoulder area, provided excellent breathing resistance in any position and stabilized the swimming position [Image 20].

As a result, the volume of the breathing bag increased slightly from about 7 to 8 liters compared to the “Dräger 138”. The pocket for balancing weights was now placed on the side of the breathing bag facing the diver’s back.

Image 19 Comparison of the breathing bag shapes, left: “Dräger Small Diving Device 138”, right: “Leutnant Lund I + II”. The breathing bags of the closed-circuit devices “Leutnant Lund I and II” received a new shape with two bulges on the left and right above the access to the soda lime container, unlike the “Dräger Small Diving Device 138”. Graphic: H. Knüfermann

The breathing valves of the “Leutnant Lund I” were located in the device-side hose connections [Image 21 left] and contained valve discs made of “mica,” a mineral from the group of “sheet silicates.” Dräger used these in valves for several breathing devices. Mica valve discs were very light, functioned durably with much less wear than the then-common “flap valves” made of rubber, and had high stability. However, the small, lightweight precision pressure spring made of stainless-steel spring wire for pressing the valve discs was the weak point of the construction [Image 22 right]. The high concentration of O2 and CO2 in the breathing air led to a redox reaction even with this treated steel, resulting in frequent replacements.2

The successor to this “Leutnant Lund I,” the Dräger “Leutnant Lund II” (see further description), later received a new lightweight rotary valve mouthpiece made of sea-water-resistant polymer with integrated breathing valves and valve discs with pronounced viscoelastic behaviour. The elastic properties of these new “rubber flap valves,” which are still commonly used in almost all breathing valves today, made a pressure spring unnecessary.

Although pure oxygen closed-circuit devices are generally dived without a buoyancy unit, there must be a balance between buoyancy and weight. To achieve this hydrostatic balance, especially flat lead weights shaped for the rear pocket of the vest were provided for the “Lund I” [Image 23]. At a maximum diving depth of 10 m, the optimal “hovering state” of the device was between 4 and 5 m with a slightly filled breathing bag 3.

Inhalation and exhalation (according to Archimedes’ law), as well as manual addition of oxygen via the hand valve during descent, or release of the excess gas via the nose and mouth nose and mouth during the ascent finely tuned buoyancy control. This of course included the buoyancy of the of the diving suit, which additionally had to be compensated with a weight belt. “Diver safety collars” (not intended for buoyancy adjustment) like those used on later hard-shell combat swimmer devices (LAR) worn on the chest were not common for devices in “vest” construction.

The quick donning and doffing of an oxygen closed-circuit device is essential for military operations. This requires a carrying and fastening system that can be handled blindly even underwater. The vest, consisting of front and back parts, was lifted over the head at the shoulder sections and lowered onto the shoulders through the neck opening; O2 bottles in front, breathing bag in the back. The two parts of the vest “are secured against each other by two side straps and a crotch strap, which are hooked onto the bolts of the quick-release mechanism”…. “First, the crotch strap is hooked onto the bolt, then the side straps are passed through the side loops of the chest part and also secured on the bolt one after the other. A locking pin prevents the straps from slipping off again.”(“werden durch zwei Seitengurte und einen Schrittgurt gegeneinander gesichert, indem sie auf den Bolzen des Schnellöffnungsorgans gehakt werden“…. „Zuerst wird der Schrittgurt auf den Bolzen gehakt, danach werden die Seitengurte durch die seitlichen Ösen des Brustteils geführt und nacheinander ebenfalls auf dem Bolzen festgelegt. Ein Sicherungsstift hindert die Gurte, wieder abzugleiten“4

By today’s standards, this attachment variant may seem somewhat “prehistoric” and hardly allow for quick donning and doffing of the device. However, former combat swimmers of the 1950s and 60s confirm the opposite. Sufficient training led to astonishing records. The central closure [Image 25] could be opened with a single hand movement, allowing the diver to quickly separate from the device.

This new “Leutnant Lund I” understandably brought significant improvements in operational possibilities for more extensive tactical undertakings. It was used not only by the “Froskemenn” of the Norwegian Navy but also found buyers in limited quantities among other Scandinavian naval units [Image 26]. Further delivery to other nations probably hardly took place, as the Drägerwerke already completed the “Leutnant Lund II” a few months later.

2 Analysis Dräger SAFETY, March 2003, on the occasion of the last possible Dräger repair of my own “Leutnant Lund II”

3 Personal experiences from decades of diving with the “Leutnant Lund II”

4 Original text, Dräger user manual “Leutnant Lund II”

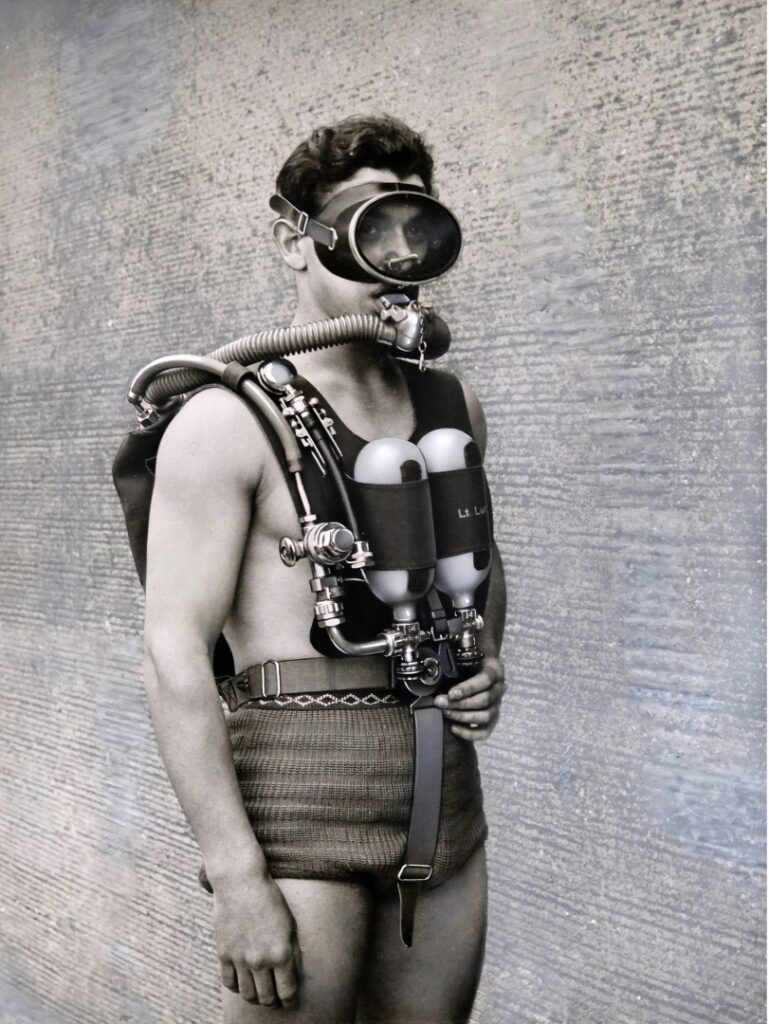

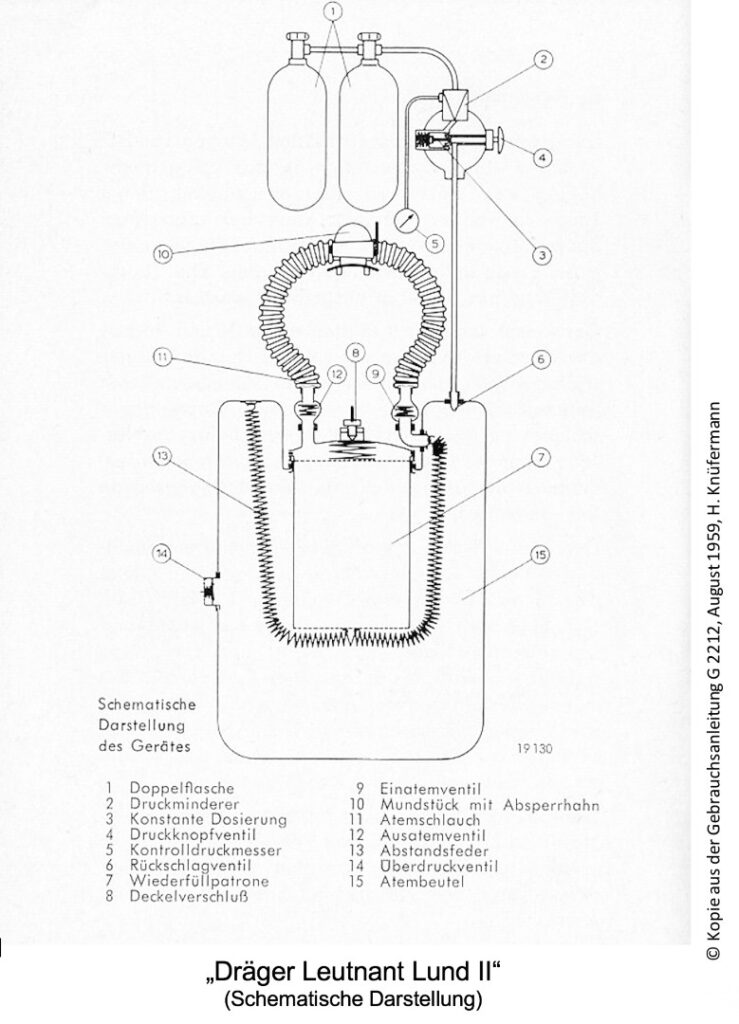

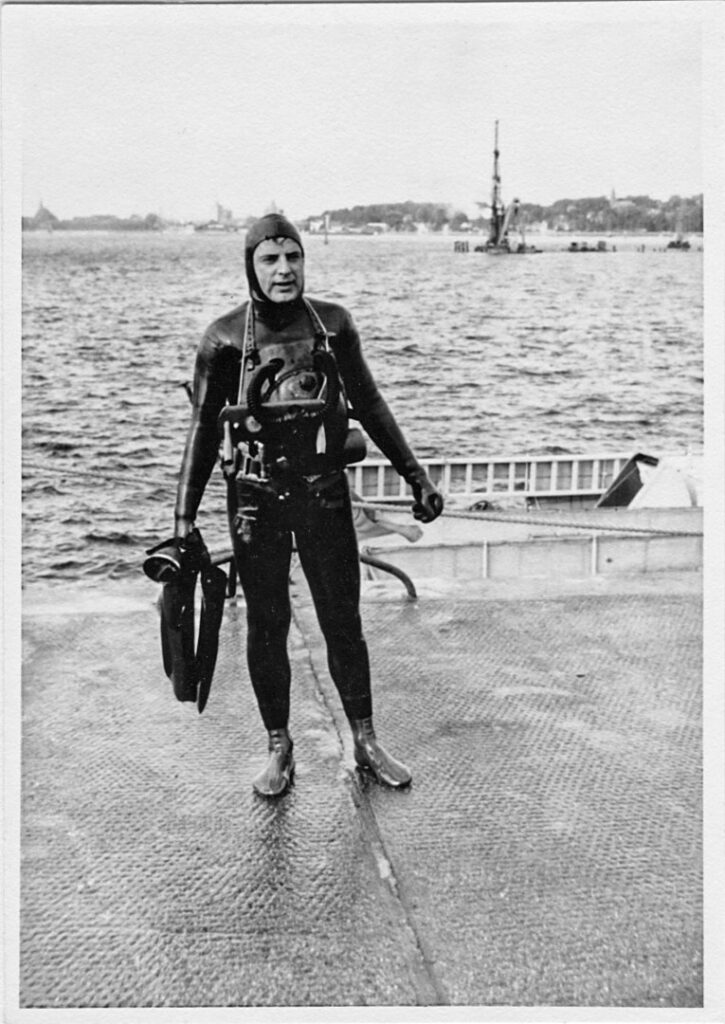

The Oxygen Diving Apparatus “Leutnant Lund II” (Dräger Drawing No.: T3600)

For many, the “Leutnant Lund II” diving apparatus is the epitome of a legendary closed-circuit oxygen device. Manufactured by Dräger-Werke from 1954 in collaboration with Lieutenant Lund, the first commander of the “Marinens Froskemannsskolen Horten” in Norway, it was used worldwide by numerous naval units until the mid-1960s. Although designed exclusively for military use, it also found its way to civilian divers here and there. Even today, the “Leutnant Lund II” is highly sought after and has lost none of its mystique.

Even though the “Leutnant Lund II” had considerable renown, it was, with a few changes, an identical copy of the “Leutnant Lund I.” In principle, the “Lund I device,” with which the frogmen of the Norwegian and other Scandinavian navies operated, was largely mature and suitable for military use. However, there was soon a need for technical corrections, which Lund (by then Captain Lieutenant) had implemented according to his specifications and in consultation with chief engineer Hermann Tietze.

The biggest problem was the regularly occurring malfunction of the overpressure valve. The overpressure valve of the “Leutnant Lund I” was taken from the “Dräger Small Diving Device 138,” where it worked reasonably reliably for civilian use for many years. However, the valve on the back of a combat swimmer device experiences greater stress in use and quickly fails. Disassembly and cleaning of the valve were a daily occurrence.

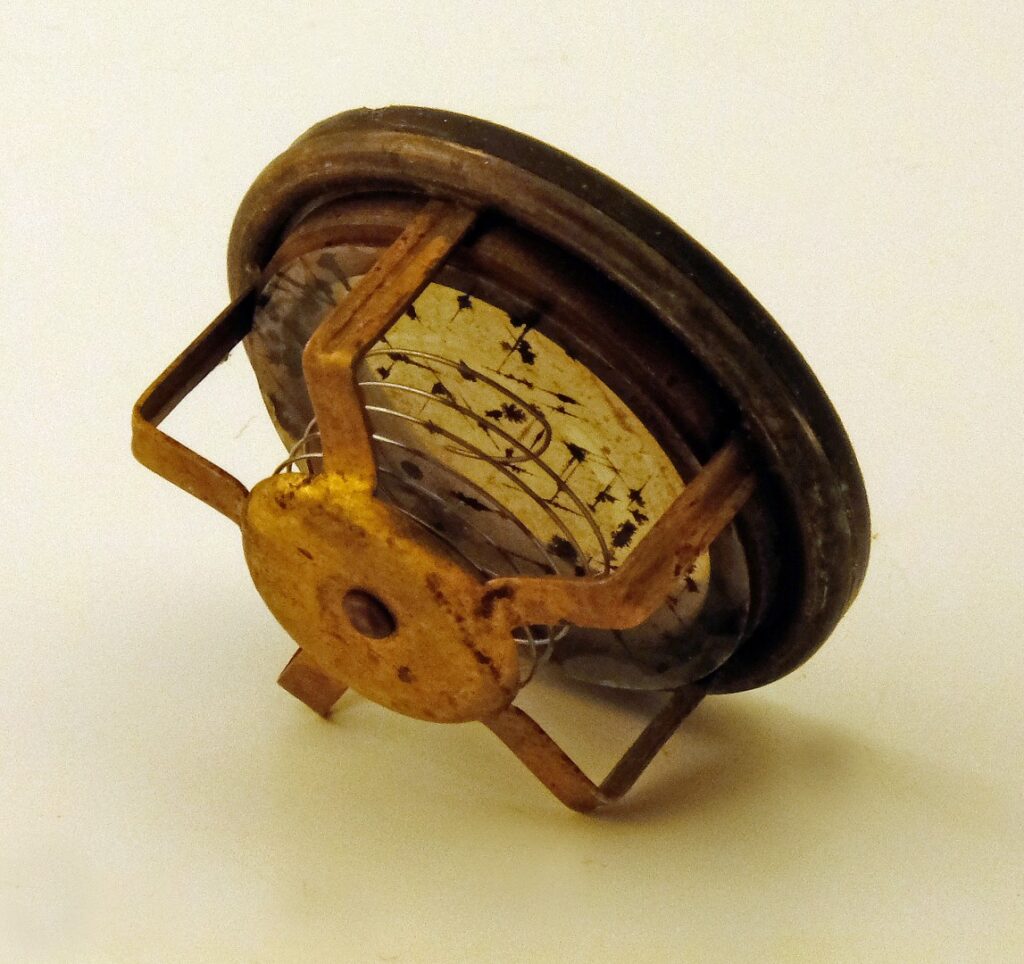

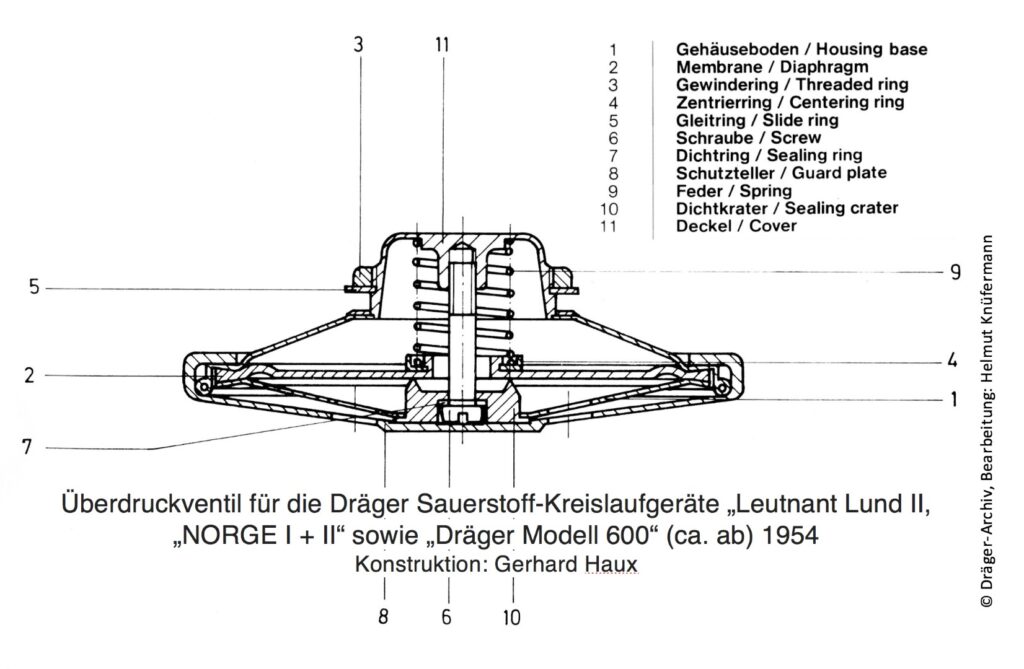

Gerhard Haux, later chief engineer of Dräger-Werke, received the task from his then-boss Hermann Tietze in his younger years to design a new overpressure valve [Image 27] for the “Leutnant Lund device.” Mr. Haux wrote in 2002: “Among the many details that needed improvement at the time, I must particularly highlight an overpressure valve for the breathing bag that caused constant trouble in its original design. Executed as a pure brass construction and equipped with a laboriously fitted spring-loaded sealing cone, this valve became leaky even with the slightest contamination. Not to mention so-called cold welding, which prevented the valve from opening correctly after longer storage. Eventually, I found a solution that solved all problems at once. The new overpressure valve for breathing bags was equipped with a membrane translation. Sealed on a stainless-steel seat with a relatively soft neoprene membrane, reinforced by a precisely balanced spiral spring. The valve opens with the desired setting extraordinarily reliably, precisely, noiselessly, and is immediately ready for use even after months of inactivity. The susceptibility to contamination is minimal because any foreign body on the sealing seat is elastically enclosed by the soft membrane. This development is now over 30 years old but still up to date. What more could a designer want?”

This valve was set to a breathing bag overpressure of 15 cmWS and functioned without problems in the subsequent Dräger oxygen closed-circuit devices in “vest” construction.

In addition, there was a modification of the oxygen bottle position. The two horizontally arranged oxygen bottles on the chest panel of the “Leutnant Lund I” were “hydrodynamic unfavourable.” They were changed for the “Leutnant Lund II” to a vertical carrying position [Images 28 and 29]. A small but effective correction, which should have a positive impact during longer swimming distances.

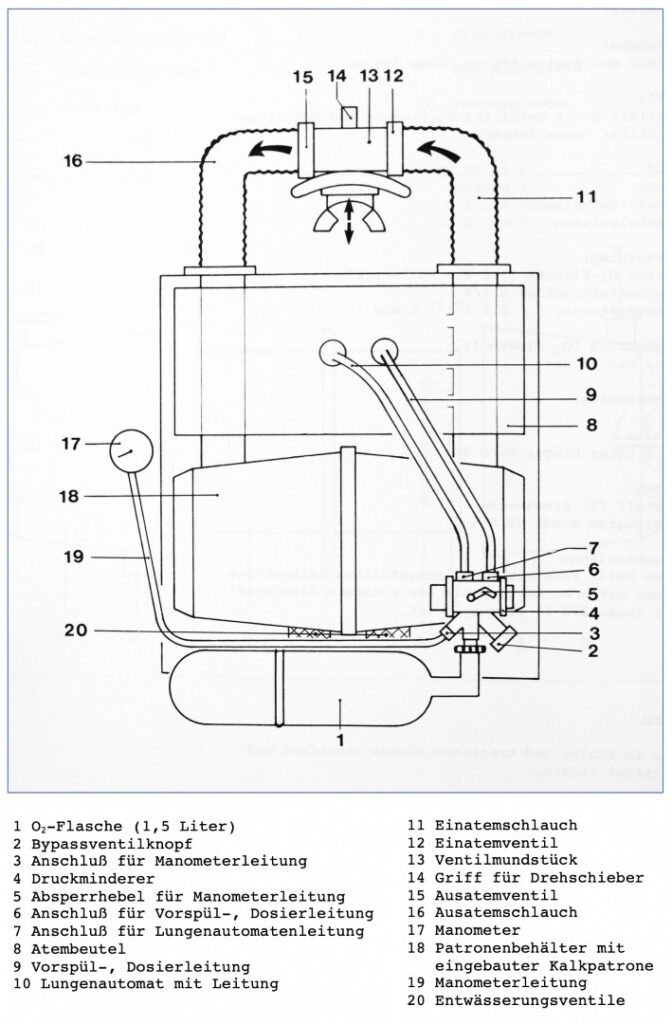

1 Double bottle

2 Pressure reducer

3 Constant dosing

4 Push-button valve

5 Control pressure gauge

6 Non-return valve

7 Refill cartridge

8 Cover cap

9 Inhalation valve

10 Mouthpiece with

stopcock

11 Breathing tube

12 Exhalation valve

13 Spacer spring

14 Pressure relief valve

15 Breathing bag

Another change to the “Leutnant Lund I” concerned the mouthpiece.

The inevitable ingress of water into the mouthpiece—especially after resuming use of the previously removed device underwater—and the resulting “gurgling and bubbling” when breathing were not only unpleasant over time but also created noises that, however slight, were transmitted through the water. This did not meet the military requirement for noiselessness.

The only bubble-free solution was to drink or drain the water by turning the body, which could result in wetting the soda lime and reducing its absorption capacity, leading to a dangerous increase in CO2 concentration in the breathing circuit.

Drägerwerke designed a new, also sealable mouthpiece for the “Leutnant Lund II,” but with a hand-operated drainage screw in the extended lower part of the brass housing. Briefly turning this closing screw counterclockwise opened the water-filled area slightly and allowed it to be blown out with a moderate breath while simultaneously pinching the exhalation corrugated hose—a betterment, but not completely bubble-free.

However, the weight of the mouthpiece was so great that a chin support was designed to relieve the jaw muscles [Images 31 and 32]. It was not until the later versions of the “Leutnant Lund II” that a lightweight “rotary valve mouthpiece” made of seawater-resistant polymer was introduced, with built-in control valves that had previously been in the device-side corrugated hose connections, as described.

As with many designs that prompt changes during daily use, details were constantly corrected, which are not further detailed here. “Those who search for mines are closest to God.” This dark humour of the World War II mine seekers remains relevant for the work of mine divers today. The main tasks of minesweepers end where mine clearing devices can no longer operate. These are usually confined spaces, such as harbour basins, canals, or specific points at sea, where mine divers are deployed (today supplemented by underwater drones).

Since sea mines and similar explosive devices register minimal acoustic and magnetic distortions, only special diving devices are suitable for this purpose.

“Leutnant Lund I”.

32 right: Mouthpiece of the Dräger rebreather “Leutnant Lund II” with drainage screw and chin rest. Photos: HK

The “Leutnant Lund II” was used for these operations up to a depth of 10 m, but in a “non-magnetic version.” Almost all parts of the device could be manufactured in a non-magnetic version at Drägerwerk. An exception was the oxygen bottles made of a ferromagnetic high-alloy steel.6 “Demagnetization” was required. Dräger arranged the demagnetization (using the alternating field method) for these bottles at the “Magnetic Testing Station Kiel-Friedrichsort” through the “Testing Station 71 for Naval Weapons” in Eckernförde. The demagnetization was carried out from 1956 according to the then-new rules of the NATO Standardization Agreement (STANAG 1131).

Ferromagnetic solids cannot be permanently demagnetized. Magnetic alternating fields in the environment cause the loss of the magnetic signature. Therefore, after measuring the magnetic remanence at intervals, repetitions were necessary.

The question of using non-magnetic lightweight metal pressure bottles made of aluminium would be justified, as the Air Force already used them at that time for fixed installations in jet aircraft. However, the “German Pressure Vessel Regulation” did not yet allow the use of aluminium pressure bottles for “portable breathing devices” at the end of the 1950s.

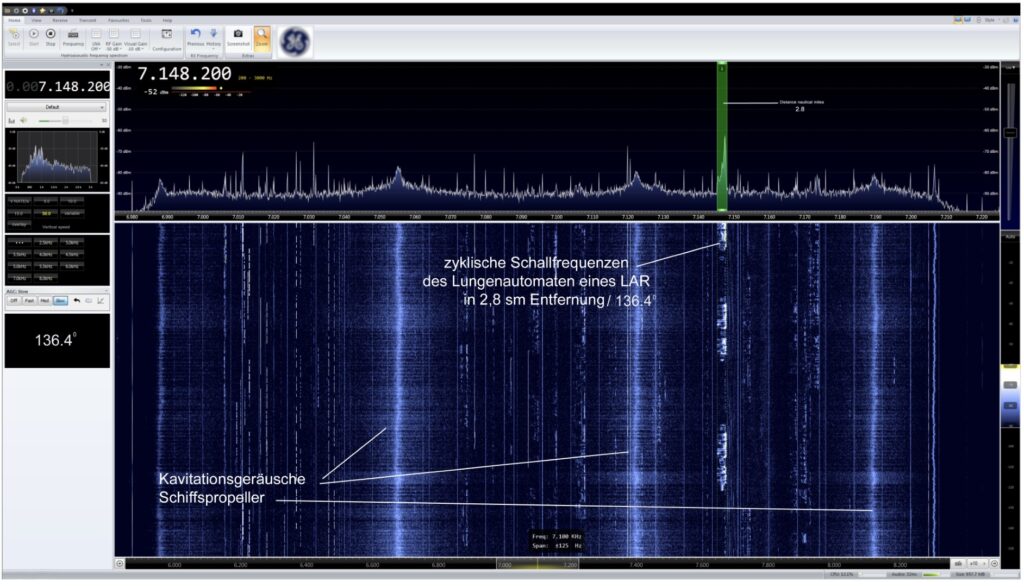

In addition to the non-magnetic property of military closed-circuit devices, the requirement for noiselessness is an important factor. The acoustic effect of even small bubbles is significant and detectable over greater distances with appropriate underwater sensors due to the underwater sound speed (of 1480 m/s). Passive distance and direction measuring systems filter out the smallest sound sources of different frequency ranges from the consistently present “noise carpet.” The risk of detection when using not completely closed-circuit devices is very high.

The Dräger “Leutnant Lund II,” as well as the other described closed-circuit devices in “vest” construction with constant oxygen dosing and an overpressure valve, did not sufficiently meet this requirement. Occasional unintentional or intentional venting of an excessive gas volume from the breathing bag or through the mouth corners led to bubble formation.

For this reason, the later lung-automatic regeneration devices of the chest-worn “hard-shell” construction (LAR) are much better suited for undetectable operations. They supply oxygen only “on demand,” have no overpressure valve, and possess a hermetically sealed breathing circuit.

However, the lung-automatic functional principle had not yet been developed for Dräger oxygen closed-circuit diving devices at that time. Therefore, the “Dräger-Leutnant Lund II” represented a maximum development stage of military oxygen closed-circuit diving devices for a long time.

Many naval units worldwide adopted the device. It proved itself in countless operations. An overview of the purchasing nations and the quantities produced remains hidden to this day. Nevertheless, this closed-circuit device, alongside English, Italian, French, and American devices, was widely distributed not only in NATO states but also, as mentioned, in eastern states via indirect routes.

Drägerwerke owes the development of the first oxygen closed-circuit swimming diving devices for military use in the early 1950s significantly to the highly dedicated Norwegian naval officer Lieutenant Lund. Therefore, the creation of these devices is also closely linked with the cooperation of the Norwegian Navy and the establishment of the first “Norwegian Frogman School.”7

6 Pressure vessel steel according to DIN 17155

7 “For Drägerwerk, the Norwegian Navy had long been an excellent customer. For example, with the Norwegian Lt. Lund, the famous closed-circuit oxygen devices for combat swimmers were developed, which then carried his name around the world,” wrote Gerhard Haux in 2002 in his book “Typisch Haux.”

Ove Lund, an exceptionally creative and inventive naval officer, not only worked on closed-circuit oxygen devices in collaboration with Hermann Tietze, but also had diving suits manufactured according to his own designs, created decompression tables based on his calculations, developed mixed gas diving devices, as well as compressed air diving devices and pressure chambers, and commissioned further diving technology according to his ideas. He tragically died in the Oslofjord at the age of 32.

In August 1956, he lost his life while attempting to reach a diving depth of 90 meters with his self-designed and Dräger-manufactured (“NITROX”) mixed gas diving device “Leutnant Lund III”. Although the course of the accident is documented, the causes have not been conclusively clarified to this day, more than 60 years later.8

Following the accession of the Federal Republic of Germany to NATO in May 1955, the founding of the Bundeswehr in November 1955, and the reintroduction of military structures in West Germany, the Ministry of Defense set the course for the establishment of new special units. The increasingly tense situation of the “Cold War” further contributed to the prompt establishment of small combat units. Six years after the first deliveries of the “Leutnant Lund I+II” devices by Drägerwerk to various naval units worldwide, the Bundeswehr also equipped the German combat swimmers of the newly established Combat Swimmer Company in 1958 with these devices [Image 38]. By the mid-1960s, the “Leutnant Lund II” in use by the Bundeswehr (and also by other German special units), until it was replaced by the then-new Dräger “LAR II” in hard-shell construction. The tragic accident in which Captain Lieutenant Lund lost his life during a diving attempt off the Norwegian coast did not halt the development of the projects he had initiated together with Drägerwerke. The Royal Norwegian Navy continued the collaboration with Dräger.

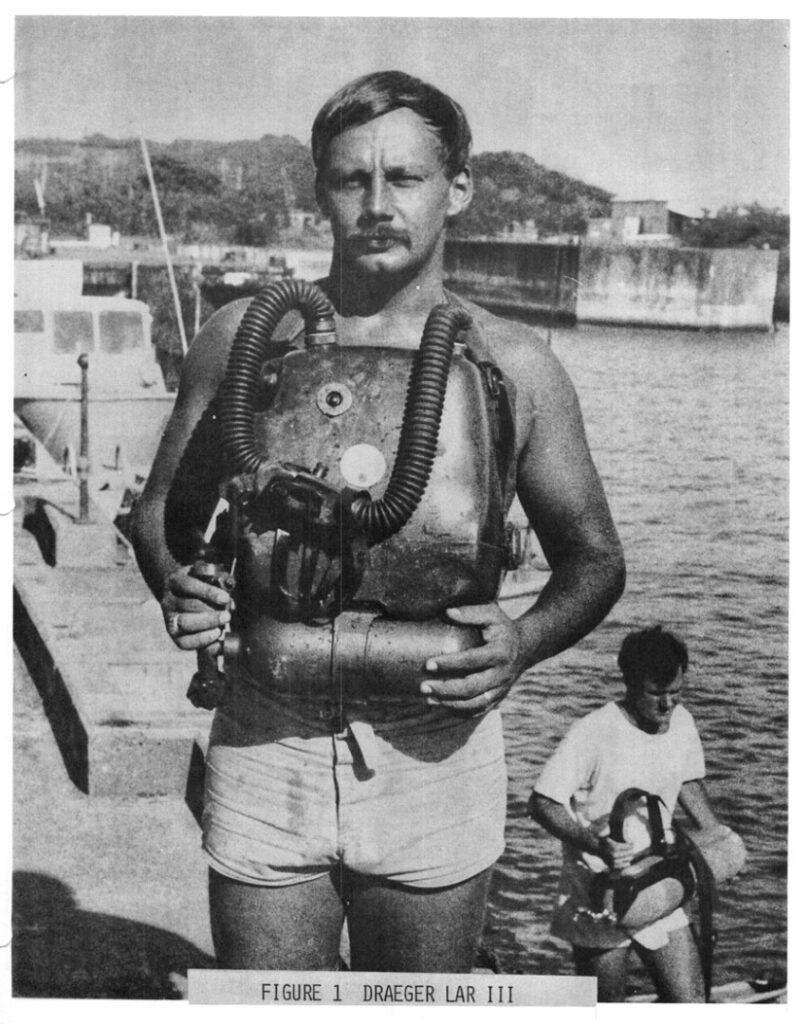

The oxygen diving apparatus “NORGE I” (Dräger drawing no.: T10200)9

Combat swimmers are sporadically exposed to particularly high loads. The measured breathing minute volumes 10 of about 30 l/min and an O2 requirement of about 1.2 l/min during moderate fin swimming can increase manifold under high physical demands. Breathing limit values of more than 120 l/min with an oxygen requirement of over 4 l/min are quite possible. The “Leutnant Lund II” reached its limits with this throughput. The cross-sections of the breathing hoses and control valves were too small for these extreme loads, and the breathing resistance increased exponentially. Furthermore, the amount of soda lime in the “Leutnant Lund II” was hardly sufficient to bind the CO2 produced under these loads. Therefore, from 1957 onwards, Dräger, at the request of the Norwegian Navy, produced a modified version of the successful “Leutnant Lund II,” which continued to be produced.

Gerhard Haux, an engineer under the direction of chief engineer Hermann Tietze in Department II of Drägerwerk, developed the oxygen swimming diving device “NORGE.” 11 The “vest” design was similar to that of the “Leutnant Lund”. The oxygen supply remained the same with the pair of 2 x 0.8-liter bottles and a filling pressure of 200 bar, as well as the constant dosing with 0.9 l/min O2 and the possibility of adding O2 through the additional valve. The device also contained the overpressure valve developed by Gerhard Haux in the breathing bag, set with a blow-off pressure of 15-16 cmWS.

The device, however, had the following changes:

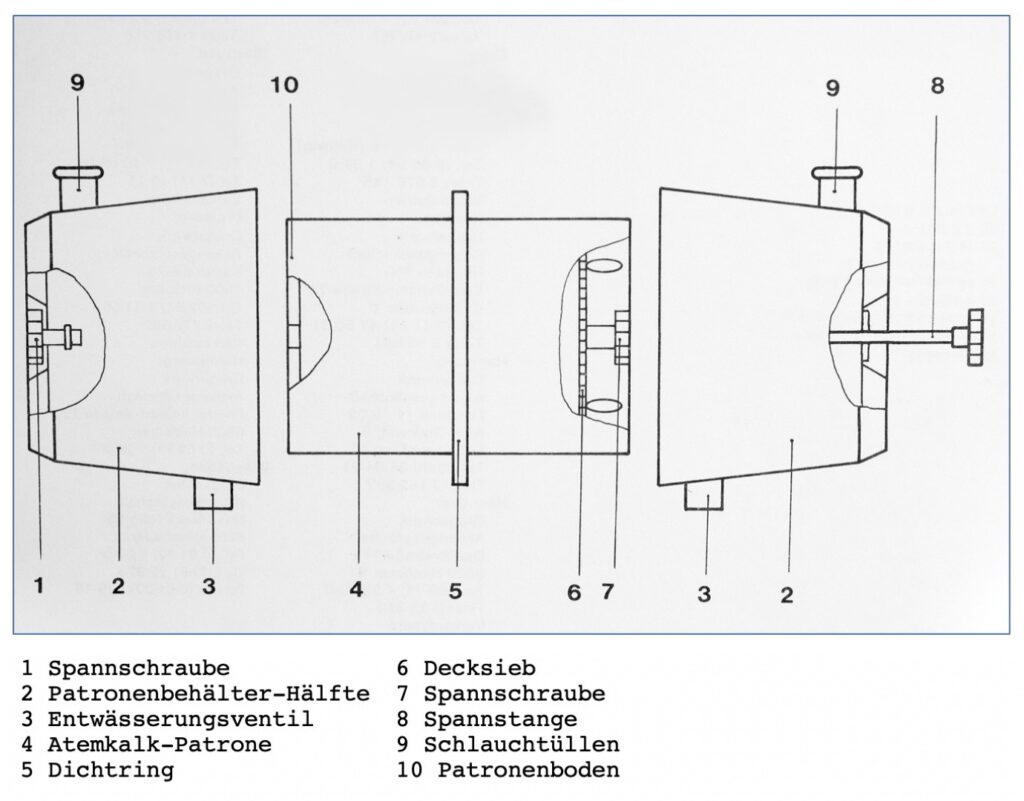

- An enlarged soda lime refill container with a net volume of 3.8 liters (with four closure hand screws for the lid, instead of the previous single closure clamp [Image 39])

- Approximately 60% expanded flow cross-sections of the new breathing hoses

- Correspondingly enlarged flow cross-sections of the control valves in a new rotary valve mouthpiece made of aluminium.

- The pressure gauge directly attached to the pressure reducer block, not foldable.

- A modified, simplified, and slightly enlarged breathing bag shape without bulges at the shoulder area, with a flexible content of 9-10 liters, see comparison [Image 40].

8 Diving History Special, Volume 14/2018, “Leutnant Lund, Biography of a Creative and Inventive Naval Officer”, H. Knüfermann

9 “NORGE I” and “NORGE II”: The “NORGE I” and “NORGE II” devices mentioned in literature and professional articles are referred to in original Dräger documents as “NORGE” and “NORGE I”. This can occasionally lead to confusion. 10 Breathing minute volume: Volume of air inhaled and exhaled per minute 11 Conversations with Gerhard Haux, as well as “Typical Haux”, Haux Publishing 2002

These modifications resulted in a reduction in breathing resistance while simultaneously increasing CO2 absorption efficiency. The reduced flow rate in the large soda lime cartridge led to more effective contact between the breathing gas and the soda lime, ensuring sufficient CO2 absorption even at very high flow rates.

The new design of the “NORGE” soda lime container, in which both the inhalation and exhalation connections, unlike the “Lund II,” led directly into the soda lime container lid, was also associated with a constructive reversal of the breathing gas circuit. Inhalation occurred here from the breathing bag through the soda lime in the container. Exhalation was directed through a closed side path of the soda lime container directly into the breathing bag without renewed contact with the soda lime [Image 41].

The “NORGE II” Sauerstoff-Schwimmtauchgerät (Dräger drawing no.: T5650)

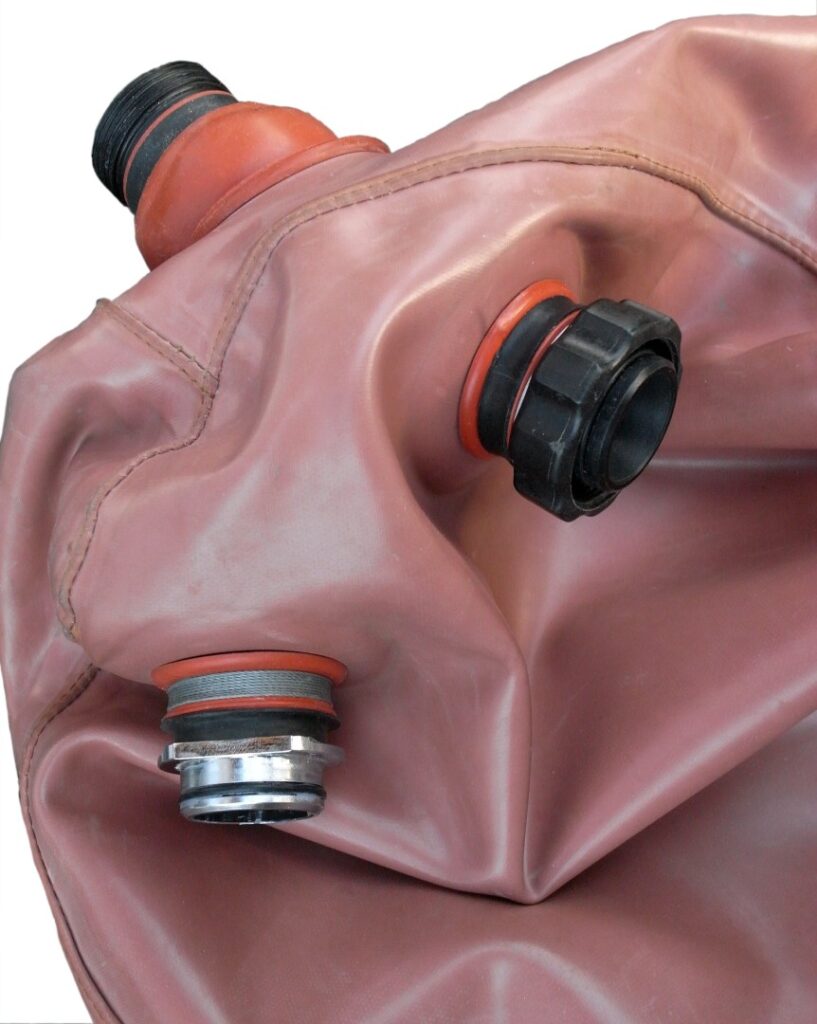

The “NORGE I” and the closed-circuit oxygen devices of the previously described design were made of reddish-brown, partially rubber-coated robust cotton fabric. However, this material became very worn with frequent use and was prone to abrasions. Drying these closed-circuit devices was labour-intensive.

In collaboration with the Norwegian Navy, the decision was made to replace this material with a strong, fabric-reinforced rubber sheet. One of the manufacturers of technical rubber already known at the time, the company “Viking Stavanger A/S” in Norway, supplied in 1959 the black, neoprene-natural rubber coated stretch fabric desired by Dräger on both sides.

The “NORGE II” was created, technically fully identical to the “NORGE I”, but in almost completely black design, including the oxygen bottles [Images 42 and 43]. After making some prototype examples of the vest at “Viking,” further production took place exclusively at the Dräger company, a manufacturing tradition that applied to almost all Dräger products.

©Dräger-Archiv, Foto:HK

This also marked the start of production of the Dräger “NORGE II” in 1960, which replaced the “NORGE I”. The “NORGE II” continued to be manufactured until the early 1970s – albeit in far smaller numbers than the original model of this type of diving apparatus, the “Lieutenant Lund II”. The Norwegian Navy was not the only customer for Dräger NORGE equipment. Both the Swedish and Danish navies used these types of rebreathers in their units12.

12 Kungl: Marinförvaltningen: “OXYGEN APPARATUS FOR ATTACK DIVERS”, Sweden, Type Draeger-Norge I (M 7382-051010) 1964. Jørgensen, S.-E.: “Development of the oxygen apparatus (rebreather) – with a focus on the apparatuses used in Denmark”, 2013. “The first diving apparatus used by the Frømandskorpset was the Lt. Lund II, this was followed by Model Norge I and after this LAR V was adopted”, 02/2018. Krange, E.: “FROM THE HISTORY OF NAVY DIVING IN NORWAY”, Erkra Forlag Kristiansand 1994.

Photo: HK

The “Model 600” Sauerstoff-Schwimmtauchgerät (Dräger drawing no.: T5421) [Fig. 44]

The “net times” of underwater stays for combat swimmers are shorter compared to those of mine or ship divers. A combat swimmer is an “all-rounder” who must also be able to fulfil their mission safely over a wide range of operations above water. Experience shows that a closed-circuit device with an appropriate oxygen supply, such as the “Leutnant Lund” or the “NORGE,” with a usage duration of about 90 minutes, is sufficient for this purpose.

However, in remote and unpredictable amphibious operations with extended timeframes, situations may arise that require even longer usage durations for multiple dives during a mission. Thus, exceptional missions demand corresponding equipment designs.

In April 1965, the engineering department II of Drägerwerk designed the “Model 600” according to the specifications of military clients [Images 45 and 46]. It is likely that the Norwegian Navy was once again the source of ideas for this model, a modified version of the Dräger “NORGE I” with 2 O2 bottles, each with a capacity of 1.5 liters and a filling pressure of 200 bar, corresponding to a 600-liter oxygen supply as breathing gas. According to the user manual, this allowed a usage duration or dive time of 180 minutes, which could be further extended by economical oxygen consumption under light underwater loads.

The large soda lime refill container and the large breathing hose diameters with the correspondingly dimensioned flow cross-sections of the control valves of the “NORGE I” were retained. All other components also matched those of the “NORGE I.” Only the foldable pressure gauge for checking the bottle filling pressure was taken over from the “Leutnant Lund II,” unlike the “NORGE I.”

Despite the lighter oxygen bottles made of aluminium used for this type of device for the first time, the “Model 600” weighed just under 20 kg, certainly less significant underwater. Compared to the weight of the “Leutnant Lund” at about 13 kg and the approximately 15 kg “NORGE,” this was a “sporting challenge” for combat swimmers who also had to carry weight belts and other tactical equipment above water.

From continuous flow to automatic lung control

As effective and successful as all previously described Dräger closed-circuit oxygen diving devices were, they still had a weakness for use in military operations. The constant oxygen flow of 0.9 l/min required regular refilling of the breathing bag using the auxiliary valve by hand in case of higher consumption. If the bottle valve was not closed, a very low oxygen consumption could cause the breathing bag to slowly fill, the excess breathing gas to vent through the overpressure valve, or to be released through the corners of the mouth, sending telltale bubbles to the water surface. Strictly speaking, these were therefore “semi-closed systems,” although described as “closed-circuit oxygen diving devices.”

Meanwhile, closed-circuit oxygen diving devices from foreign manufacturers were known to have their breathing gas supply refilled by an integrated lung demand valve only as much oxygen as the diver consumed, and thus did not require an overpressure valve, essentially fully closed systems. For the Dräger engineers, as well as for the responsible parties of the Federal Navy, this was a consideration to rethink the designs of combat swimmer diving devices.

Gerhard Haux commented on this:13

“In this happy small-scale development time (1960), a French development group with the G.E.R.S. device burst out of the blue. It was a sealed, extremely compact closed-circuit oxygen device for combat swimmers, worn exclusively on the chest, a substantial advance over the Lt. Lund II and the NORGE devices, objectively speaking.”

Thus, in early 1961, also at the urging of the Federal Navy, the first prototypes of a “lung automatic regeneration device” “LAR” in the chest-worn “hard-shell” design began to be developed in Drägerwerk’s Department II, which in the following years replaced the legendary “Leutnant Lund II,” the “NORGE I” and “II,” as well as the “Model 600.” A series of test devices with new insights and modifications in the following years led to the successful “LAR” diving equipment series for combat swimmers, which are still manufactured today in technologically highly developed versions.

Part 3 of this article (in the next issue of Diving History) describes the development of these first Dräger LAR closed-circuit devices in “hard-shell” design.

————————————————————————-

Presentation of the diving devices used by the “SJØFORSVARETS DYKKER- OG FROSKEMANNSSKOLEN” in Norway since its founding until 1997, large-format photos, and a training video at weblink t1p.de/os7a

Many thanks to all those who knowingly or unknowingly contributed to this article. Special thanks to Gerhard Haux and Bjørn W. Kahrs, who provided me with a lot of information that probably no longer exists as written documents, and especially to Thomas Peyn, head of the Dräger equipment and document archive, who gave me access to the historical equipment archive as well as the document archive of Drägerwerke.

Sources see part 1 of the article in Diving History 09 2018/06

13 Conversations with Gerhard Haux, as well as “Typisch Haux,” Haux Publishing 2002 14 “Oxygers 57,” a French closed-circuit diving device, developed by G.E.R.S. (“Le Groupe de Recherches Sous-Marines”, the underwater research group of the French Navy), manufacture and distribution: Fenzy/La Spirotechnique

s1

s2

s3

s4

PART 3

Dräger diving equipment for”Combat Swimmers”

Chronological development of closed oxygen rebreathers from Drägerwerke for the military use under water

Devices in “hard-shell” design

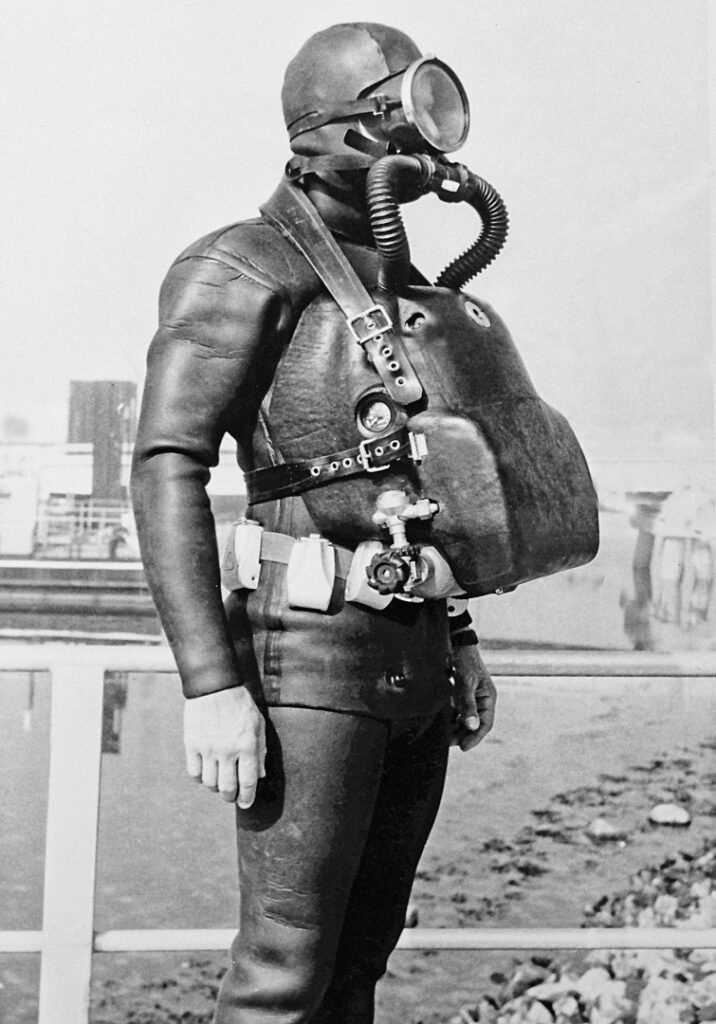

The closed-circuit oxygen diving devices in “vest” design manufactured by Drägerwerke were part of the reliable operational equipment of many combat swimmer units worldwide in the 1950s and 60s. In the course of contemporary development, comparisons were soon made with diving equipment designs from other nations.

Gerhard Haux, then chief engineer at Drägerwerke, described this in his book “Typisch Haux”1 with the following words:

“Into this happy little development time then burst, like a burst out from the blue, a French development group with the G.E.R.S.2 device (Oxygers 57). It was an encapsulated, extremely compact closed-circuit oxygen device for combat swimmers, worn exclusively on the chest, a significant advance over the ‘Lt. Lund II’ and the ‘NORGE devices’, objectively speaking.”

Thus, in Drägerwerk’s Department II and also at the instigation of Wolfgang Brinckmann, Corvette Captain and Commander of the KdoMWa3 of the Federal Navy, the first prototype models of a “lung automatic regeneration device” (LAR) in chest-worn “hard-shell” design began to be developed, which would replace the Dräger closed-circuit oxygen devices in “vest” design in the following years.

With previously manufactured closed-circuit devices in “vest” design with constant oxygen supply, overdosing with low O2 consumption could not be avoided. The result was that excessive gas volume in the breathing bag, vented through the overpressure valve or at the corners of the mouth, caused telltale bubble formation, as well as unused oxygen overconsumption. Conversely, under heavy loads on the combat swimmer and high O2 consumption, refilling the circuit by repeatedly operating the auxiliary valve (often called the bypass valve today) was required. This additional handling, which can be very cumbersome, is avoidable if only as much oxygen is supplied to the circuit as the diver consumes. Therefore, it is a comparatively better solution if the oxygen supply is regulated automatically by a lung demand valve. A lung demand valve in the breathing bag responds to an adjustable negative pressure and ensures the timely refilling of the device’s circuit. The mentioned French G.E.R.S “Oxygers 57” operated on this principle.

1 “TYPISCH HAUX,” Gerhard Haux, HAUX PUBLISHING 2002

2 G.E.R.S “Le Groupe de Recherches Sous-Marines,” the underwater research group of the French Navy (co-founders: Cousteau and Dumas). Manufacture and distribution of the “Oxygers 57”: Fenzy/La Spirotechnique.

3 The “KdoMWa, Command of Naval Weapons in Kiel,” a specialized command of the Federal Navy responsible for all matters of armament. It oversaw schools and testing facilities for naval weapons.

The combat swimmers of the Federal Navy in Germany, equipped with the “Leutnant Lund II” from Dräger, already completed courses at the diving school of the French combat swimmers in St. Mandrier, a school of the “Commando Action Sous-Marine” or “Commando Hubert,” in 1959, half a year after the establishment of the Combat Swimmer Company.

The training there was conducted with the “Oxygers 57.” Compared to the previous Dräger closed-circuit devices in “vest design,” this French device was not only significantly smaller and lighter but also considerably more user-friendly for the same usage duration [Image 01]. The chest-worn design kept the back free for tactical additional equipment and allowed for very quick donning and doffing during operations. It was largely non-magnetic with an aluminium oxygen bottle, had a completely closed breathing circuit without an overpressure valve, and featured a lung demand valve instead of an O2 auxiliary valve (bypass), whose response pressure could be adjusted during the dive.

The experiences made by the German combat swimmers with this closed-circuit device were so convincing that the “Federal Office for Military Technology and Procurement” approved a request from KKpt Brinckmann in July 1960 to purchase 10 “Oxygers 57” diving devices for testing and as an impetus for an initial Dräger-LAR construction. The order was placed with the manufacturer Fenzy and delivered to the Federal Navy through the then importer Jack W. Lavanchy4 at a price of DM 1,390 per unit.

These 10 units were to be initially tested by mine divers in the swimming pool of the Navy Supply School in List on Sylt, according to the instructions of the Federal Office for Military Technology and Procurement from July 1960, and later by combat swimmers in open water.

The obvious idea of designing the first LAR device based on the “Oxygers” model was not put into practice.

realised. The manufacturing company Fenzy made the contractually the condition to be contractually signed,

“…that the German Armed Forces would neither make a replica nor be organised”. However, the Dräger engineers had their own ideas anyway, especially as Bernhard Dräger had already developed an oxygen lung power-operated oxygen dosing >>depression automaton<< 5 and in the course of the following decades

this “LAR” control system in mining equipment with closed-circuit breathing with circulatory breathing.

Drawing 03: Lung regulator >>Depression regulator<<5, scheme B – with main and auxiliary and auxiliary breathing bag, and control lever, schematic drawing 1919 by Bernhard Dräger. Source: Manuscript by J.W. Haase-Lampe, © Lisa Dräger Lübeck, 2007

Furthermore, based on Dräger’s extensive experience with respiratory and closed-circuit devices for mining, diving operations, and rescue, the initial basic ideas could soon be put into practice.

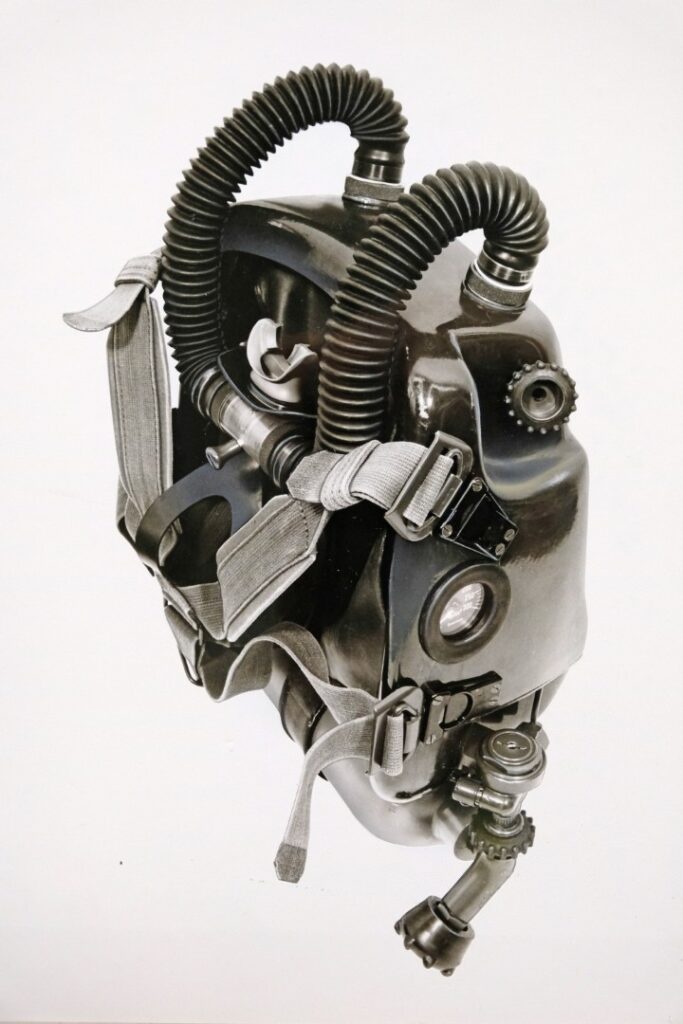

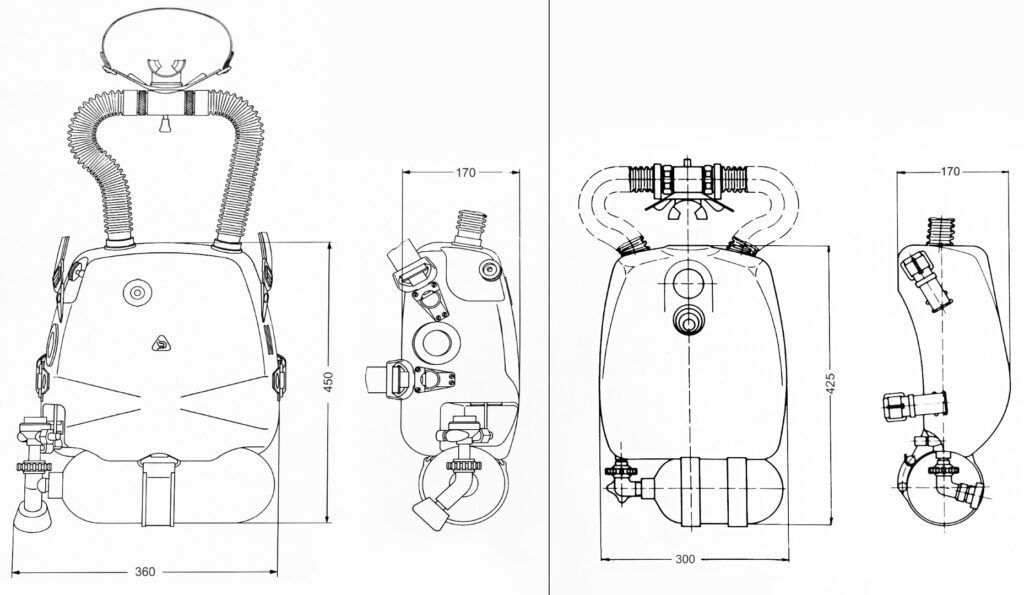

Primary requirements according to the specifications for the first Dräger-LAR design were:

- Lung-automatic oxygen supply, no constant breathing gas flow

- Completely closed circulation system

- No overpressure valve

- Separate inhalation and exhalation hoses

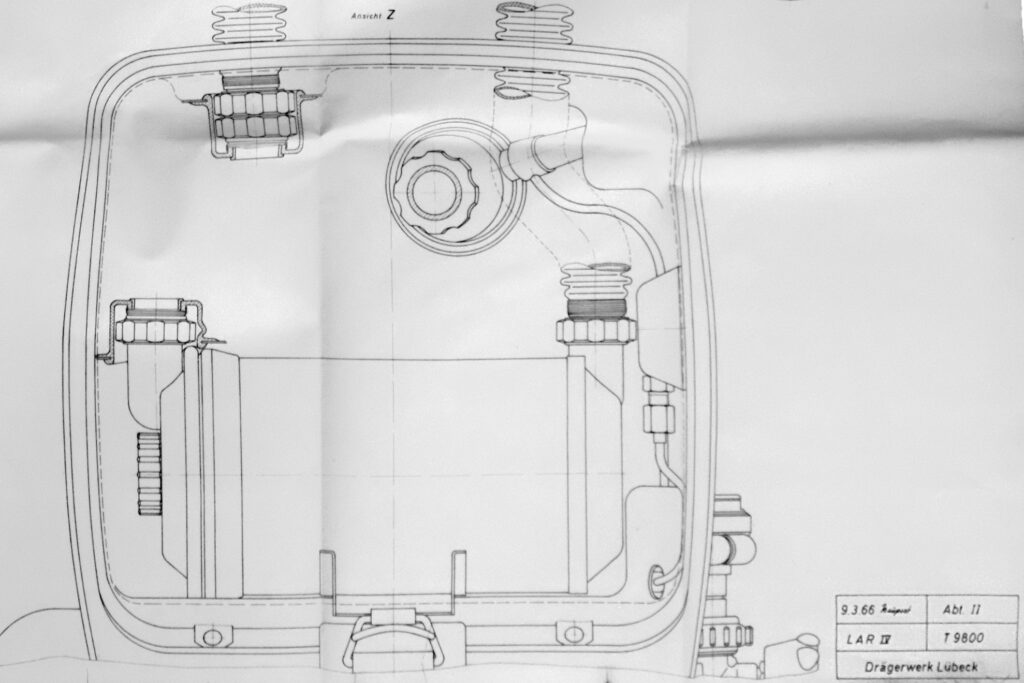

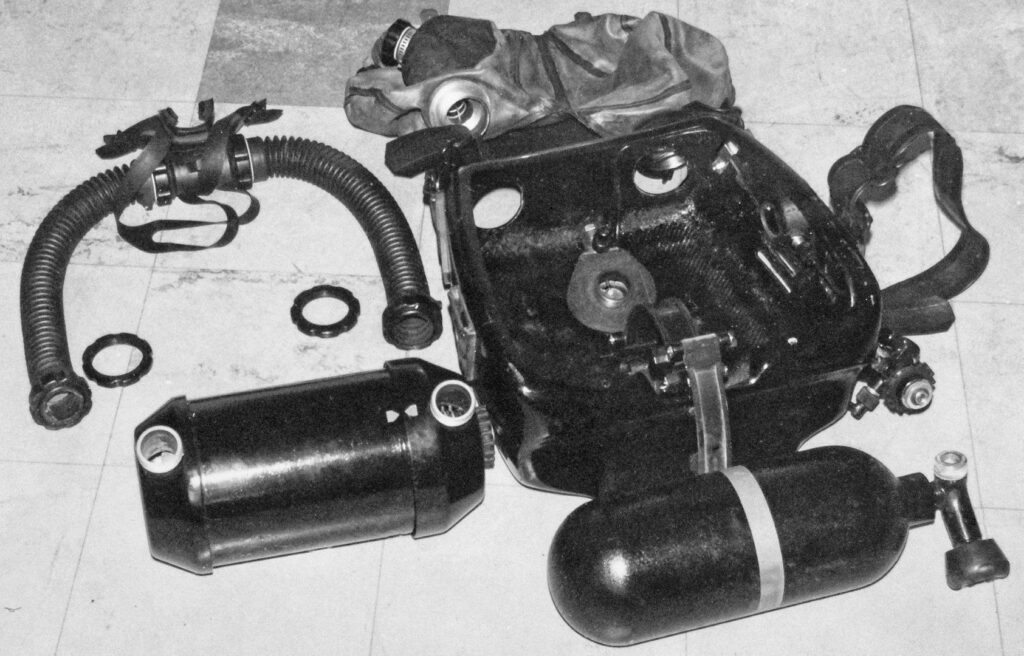

- Housing made of fiberglass-reinforced polyester resin

- Worn entirely on the chest

- A single oxygen bottle lying horizontally below the housing

- Lung demand valve, breathing bag, and soda lime container integrated into the protective housing.

Today, Dräger implements complex planning and design tasks from idea to production without significant time losses, in coordination with project and product management, and with the help of specialized software.

4 Jack W. Lavanchy, 1929-2016, diving pioneer, Switzerland, took over the exclusive distribution for La Spirotechnique in Switzerland from May 1965 and in 1968 also for Germany.

5 based on an original idea by the Frenchman Rouquayrol from 1872 (high-pressure fresh air apparatus).

In the 1960s, however, various engineers worked in parallel with “analog” methods and their own ideas for the same project, from which a final approved version was eventually chosen.

Among other things, there was a design labelled “R181,” which Gerhard Haux personally tested in Dräger’s own swimming pool [Image 04]. The impressive small design of the “Oxyger 57” likely led to the construction of this design in the fall of 1960. Data or descriptions could no longer be determined.

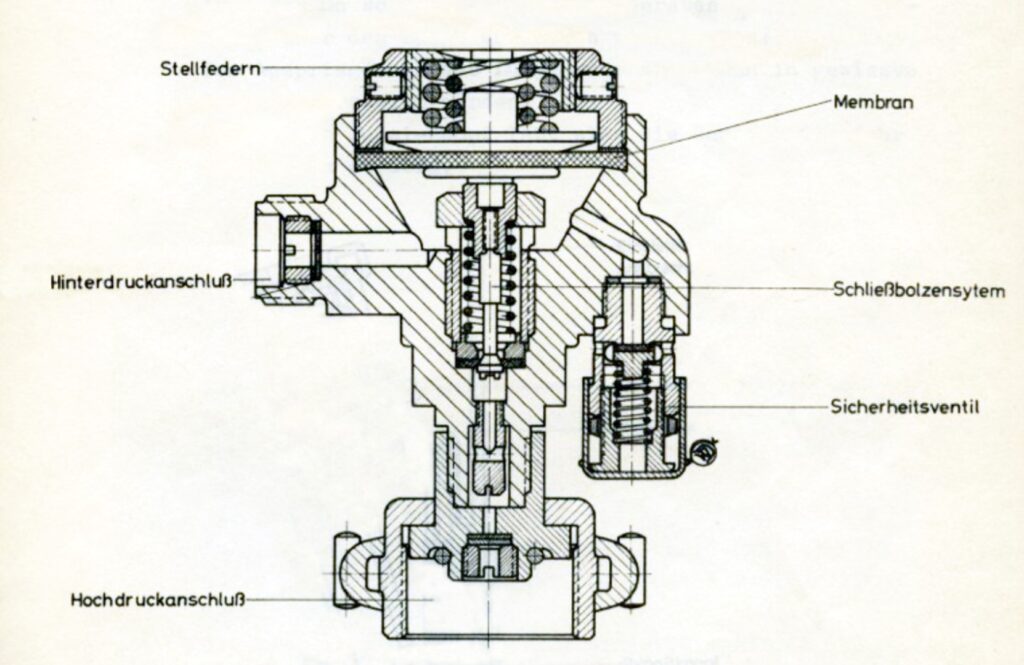

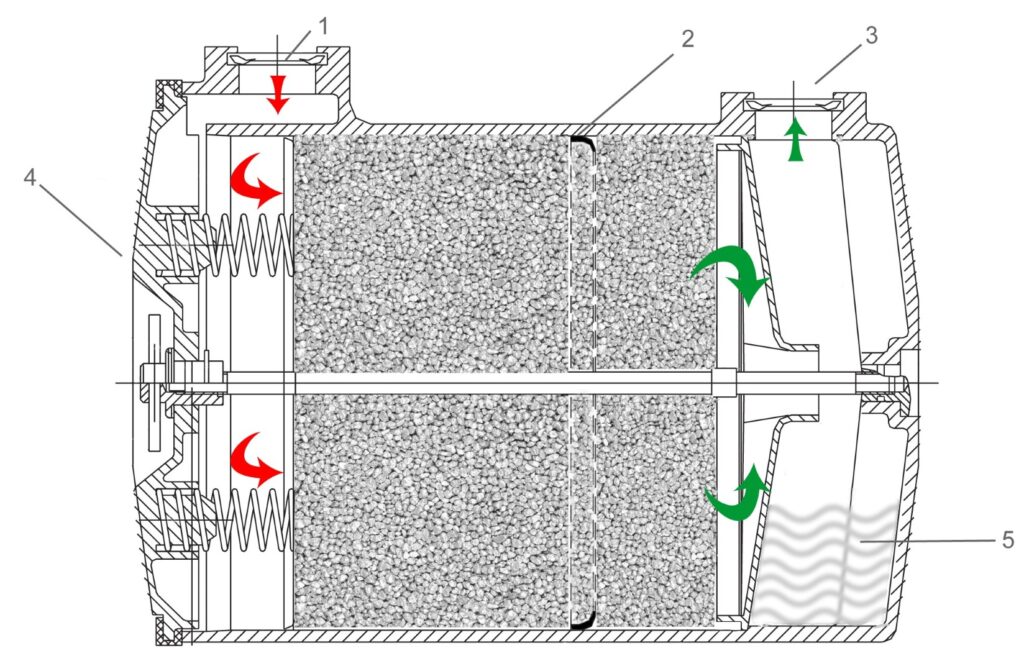

After some experimental setups at the beginning of 1961, a first LAR prototype was able to “make the leap from the drawing board to the swimming pool” [Image 05]. Most of the components came from the serial production of existing respiratory protection devices. When selecting a pressure reducer, which reduced the oxygen requirement from a 1.5-liter (steel) bottle with 200 bar high pressure to a low pressure of 3 to 5 bar, they chose an already tested version. A model with very good control accuracy and a double lever mechanism (“Dräger-Z-Werk”) that closed against the supply pressure at low gas flows was used, which was already working perfectly in existing oxygen gas protection devices.

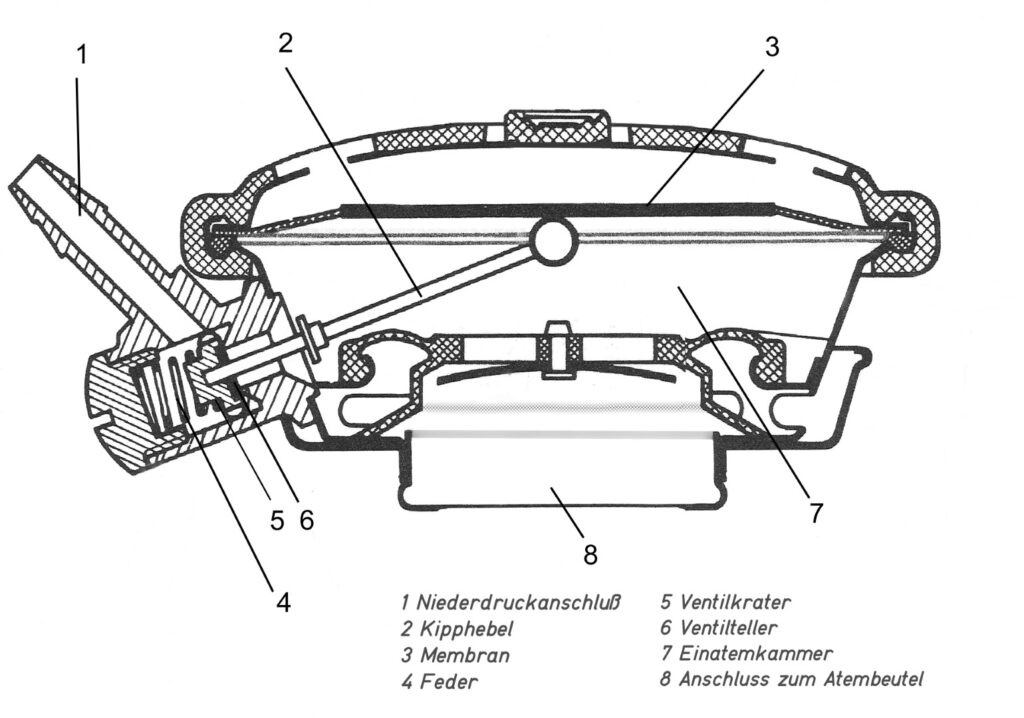

The second stage was embodied by a slightly modified single-stage lung regulator of the “PL 67 model” compressed air hose device with a rocker valve, which was centrally integrated into the breathing bag [Image 07]. The inhalation chamber of this regulator was connected to the pressure conditions prevailing in the breathing bag of the device [Image 08].

Depending on the filling level of the breathing bag, inhalation created a negative pressure that opened the rocker valve via the membrane, ensuring a supply of oxygen.

The permanently installed lime container made of metal had a capacity of about 1.8 liters and could be refilled through a laterally attached lid opening. The breathing bag, made of fabric rubberized on one side, provided a flexible volume of about 8 liters. The inhalation and exhalation valves were located in the lockable slide mouthpiece made of PC (polycarbonate). The basic functions of this “rough version” were acceptable for the time being. They immediately led to the construction of the “LAR I.”

The LAR 1

The beginning of a successful Dräger diving equipment series (Order number T5370).

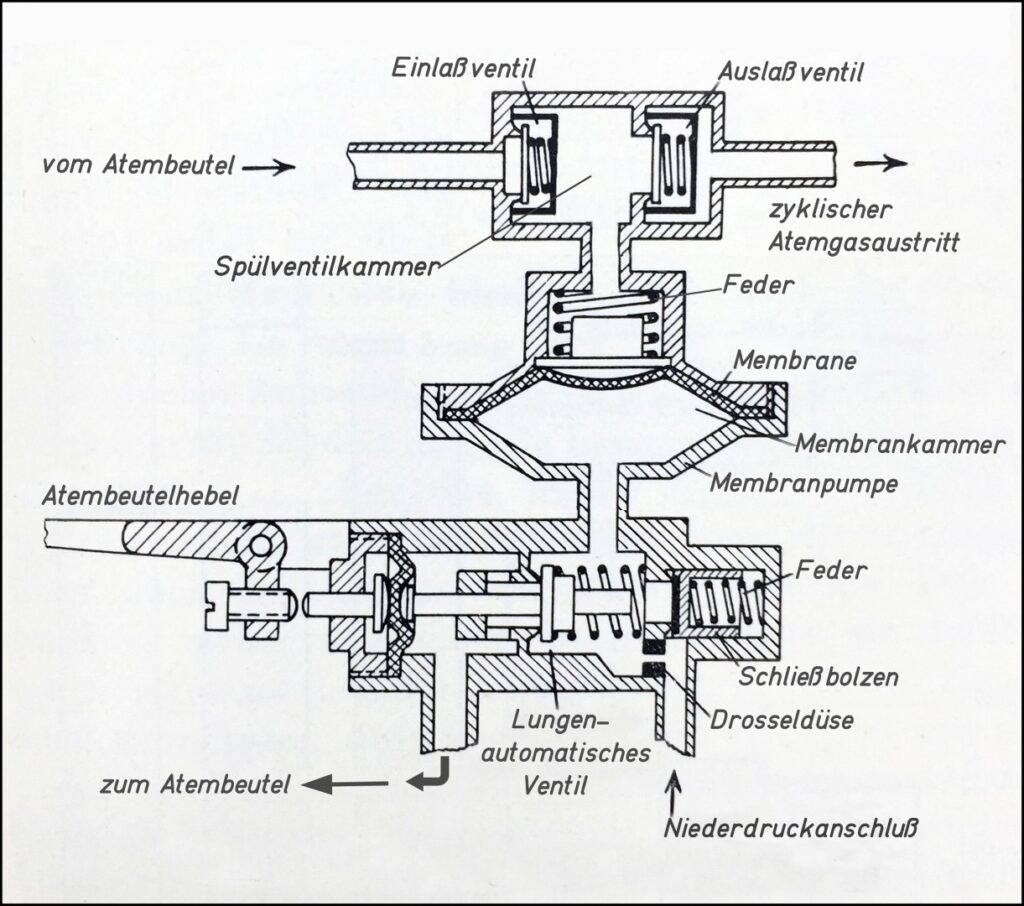

The experimental model “LAR 0” [Image 10] was the basis for the “LAR I”. It was equipped with a – at the time considered necessary – respiratory physiologically suitable component, a “flushing pump”.

In contrast to the purity of today’s oxygen in compressed gas cylinders used for breathing, with 99.999% purity, the O2 content at that time was only about 98%. One of the lightweight Dräger respiratory protection devices with a closed oxygen circuit from the 1950s, the “Dräger Mining Device BG 170/400,” was already equipped with this flushing pump. Its task was to remove the remaining 2% of “unbreathable gases” – mainly nitrogen – from the breathing circuit.

Additional factors were not decisive for the support by a flushing pump but should also not be disregarded. On one hand, the residual nitrogen from the lime container and the residual volume of the lungs increases the inert gas content. On the other hand, the nitrogen bound and released from the body tissue must also be taken into account.

The inspiratory N2 inert gas absorption does not increase with pure O2 breathing (including hyperbaric). There is no saturation of nitrogen, as it is absent in the breathing circuit. However, under the conditions of pure oxygen breathing, an (exponentially progressing) N2 desaturation occurs, depending on various solubility coefficients in body tissue groups. This is also noticeable, albeit to a small extent. The volume, depending on body weight, amounts to about 1.0 to 1.3 liters in total.

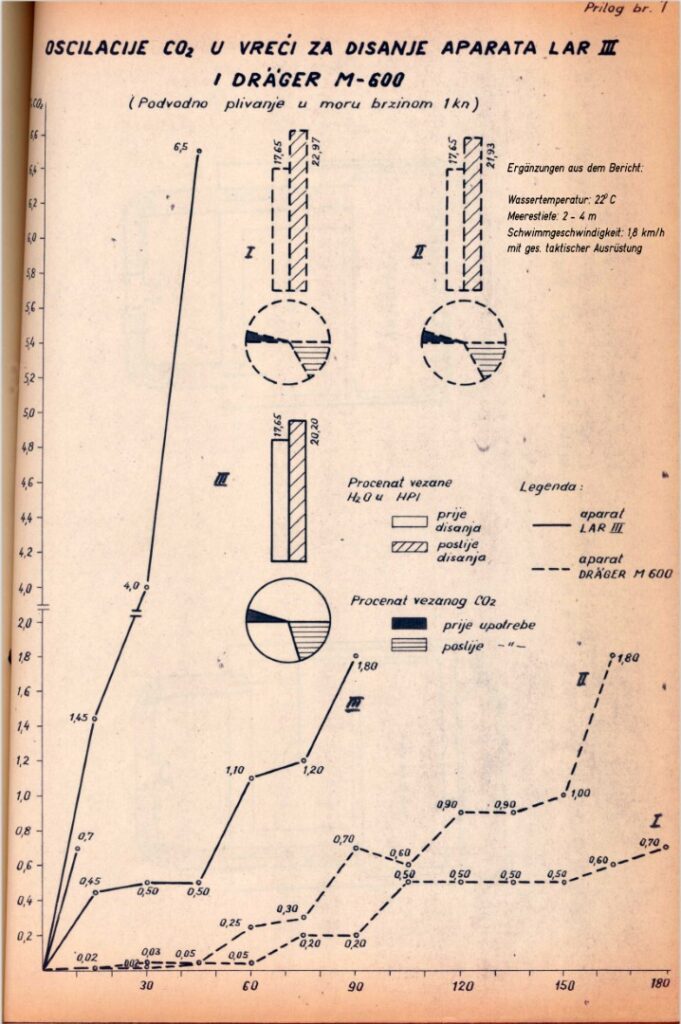

Test series with combat swimmers showed that even with longer dives and prescribed flushing processes, on average, only 76% oxygen was present in the breathing circuit.6

The flushing pump provided significant safety under these aspects. The “Dräger Mining Device BG 170/400” could be used in rescue operations without time-consuming and repeated pre-flushing of the breathing bag with oxygen.

Therefore, this flushing device was also considered appropriate in a military circuit device and the pump was built into the “LAR I” [Image 11], technically modified for use under water. 7

It was started with each response cycle of the lung regulator. The pump simultaneously drew breathing gas from the breathing circuit through a valve with each recurring opening of the lung regulator and, after exceeding a membrane chamber limit value, pushed this air through the outlet valve of the flushing valve chamber into the open water at regular intervals (the flushing quantity amounted to about 8% of the respective supplied breathing gas). This ensured that no disproportionately high inert gas content could accumulate in the breathing bag.

6 W. Boczek, J. Hilbert “Diving with Oxygen Rebreathers” Verlag Delius Klasing, ISBN 978-3-7688-2422-4

7 Experienced combat swimmers flush today when they spontaneous dive underwater.

As early as the early summer of 1961, the construction and practical tests at Dräger were completed. In July 1961, Dräger was able to offer “10 units of the lung-automatic diving device model LAR I” at a price of DM 1,479 each to the Federal Ministry of Defense. Just 14 days later, the Federal Office of Defense Technology and Procurement received an order to purchase not 10, but 20 units of the “LAR I”.

The devices were to be delivered, half to MVS8 List / Sylt and half to KdoAS9 in Wilhelmshaven, for testing by the respective combat swimmer units in troop trials. Drägerwerke confirmed the order with a delivery time of 8 months. In the spring of 1962, the Bundesmarine combat swimmers could begin testing the first specimens of the “LAR I”. However, over the following months, it became clear that this first LAR design needed to be reconsidered. The conclusion of the test report, which was officially documented only at the end of 1963, was:

“The troop trials conducted with the ‘LAR I’ diving device did not yield satisfactory results. The breathing flushing pump required significant space. The utility of the flushing pump did not meet the expectations placed upon it. The efficiency was too low, the oxygen supply was sluggish and could not adequately meet the oxygen demand—especially during rapid diving. Contrary to previous notions, a bypass valve for the lung-automatic principle of the respiratory system was necessary… The devices are not fit for troop use.” Furthermore, the device did not operate without bubbles due to the gas discharge from the flushing pump. This was the “END” for the “LAR I.”

Whether these converted “LAR I” devices were subsequently used in hall training is not recorded. Notably, in recent years, two of these devices reappeared. They were externally recognizable by a remaining round opening on the left side of the housing, which previously contained a screen to protect the exiting flushing pump air line [Image 13]. These two specimens were (probably later) equipped with 1.5-liter aluminium alloy cylinders each. One of these devices was reviewed in 2017, made dive-ready, and functioned flawlessly during a short open water dive [Image 14].

The LAR II

Construction series with great success (order code T6030)

The agreed delivery dates with the Federal Office of Defense Technology and Procurement (BWB11) made the rapid production of a successor model urgently necessary. “Corvette Captain Brinckmann, Bundesmarine (affectionately also called ‘Kleinkampfbrinckmann’12, put the pressure on us…” as Gerhard Haux wrote in his book “Typisch Haux.” Due to the unsatisfactory test results with the “LAR I,” Dräger immediately developed a new LAR model in 1963 on their own initiative, with a smaller hard-shell case made of fiberglass-reinforced plastic [Image 15] and numerous changes – under the model designation “LAR II.”

A newly designed small lung regulator with a bypass function, which could be operated from the front of the device, the no longer present flushing pump, and the…

8 Marine Supply School, List / Sylt

9 Command of Amphibious Forces, Wilhelmshaven

10 Marine Underwater Weapons School, Eckernförde

11 “BWB” Federal Office of Defense Technology and Procurement

12 Corvette Captain Brinckmann was an active officer of the Kleinkampfverband of the Kriegsmarine