Part of the History of the Auer Gesellschaft Berlin

by therebreathersite

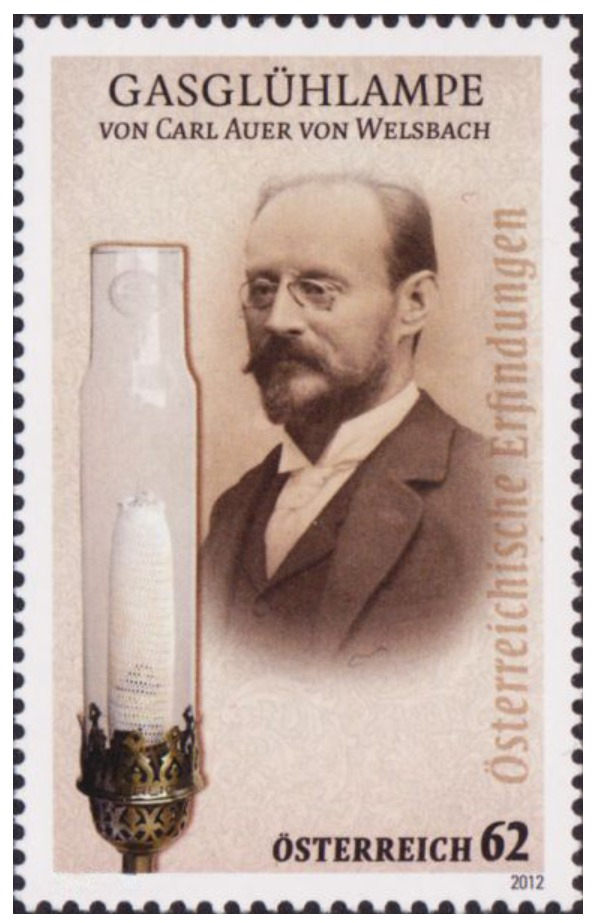

Carl Auer von Welsbach (1858–1929) was an Austrian scientist and inventor whose contributions revolutionized several fields, particularly in chemistry and technology. He is best known for his discoveries and inventions related to rare earth elements and their applications in lighting and gas mantle technology.

Born on September 1, 1858, in Vienna, Austria, Welsbach displayed an early aptitude for science and innovation. He studied at the Technical University of Vienna, where he delved into chemistry and metallurgy. During his studies, he became particularly interested in the properties of rare earth elements, a group of elements that were not well understood at the time.

In 1885, Welsbach made a groundbreaking discovery that would change the landscape of lighting technology. He found that a mixture of thorium oxide and cerium oxide, when heated, emitted a bright, white light. This discovery led to the development of the Welsbach mantle, a small fabric bag coated with these oxides, which, when heated by a gas flame, produced a brilliant and steady light. The Welsbach mantle became a significant advancement in gas lighting, replacing earlier, less efficient methods.

Welsbach’s inventions didn’t stop there. He continued to experiment with rare earth elements and their applications. In 1903, he patented the incandescent gas mantle, which further improved upon his earlier design. This innovation greatly increased the efficiency of gas lighting and made it more widely accessible.

Beyond his work in lighting technology, Welsbach made significant contributions to the field of chemistry. He isolated several rare earth elements and conducted extensive research on their properties and applications. His work laid the groundwork for further advancements in chemistry and materials science.

In addition to his scientific endeavors, Welsbach was also an entrepreneur. He founded his own company, Welsbach Gaslicht Gesellschaft, to manufacture and distribute his inventions. The company became highly successful and played a crucial role in bringing Welsbach’s innovations to markets around the world.

Throughout his life, Welsbach received numerous honors and awards for his contributions to science and technology. His discoveries continue to impact various industries to this day, and his name remains synonymous with innovation in lighting and chemistry.

Carl Auer von Welsbach passed away on August 4, 1929, leaving behind a legacy of scientific achievement that continues to inspire researchers and inventors around the world.

The Auer Corporation was a significant entity in the realm of gas lighting and mantle production, founded by Carl Auer von Welsbach in 1889. This corporation played a pivotal role in the commercialization and distribution of Welsbach’s inventions, particularly the Welsbach mantle.

Under Welsbach’s guidance, the Auer Corporation became a leading manufacturer of gas mantles and related products. The company capitalized on the success of Welsbach’s innovations, establishing itself as a key player in the burgeoning gas lighting industry of the late 19th and early 20th centuries.

The Auer Corporation’s success was not limited to gas lighting technology. It also diversified its product offerings, expanding into other areas such as metal alloys, chemical compounds, and even early attempts at electric lighting.

As the demand for gas lighting grew, fueled by urbanization and industrialization, the Auer Corporation experienced significant growth and prosperity. Its products became widely used in homes, businesses, and public spaces around the world.

However, with the advent of electric lighting technology in the early 20th century, the gas lighting industry faced stiff competition. Despite efforts to adapt and diversify, the Auer Corporation began to decline in relevance. Eventually, the company shifted its focus away from gas lighting and mantle production towards other ventures.

Although the Auer Corporation no longer exists in its original form, its legacy lives on through the continued use of Welsbach’s inventions and the advancements they inspired in lighting technology. The company played a crucial role in popularizing gas lighting and making it accessible to people worldwide, leaving an indelible mark on the history of illumination.

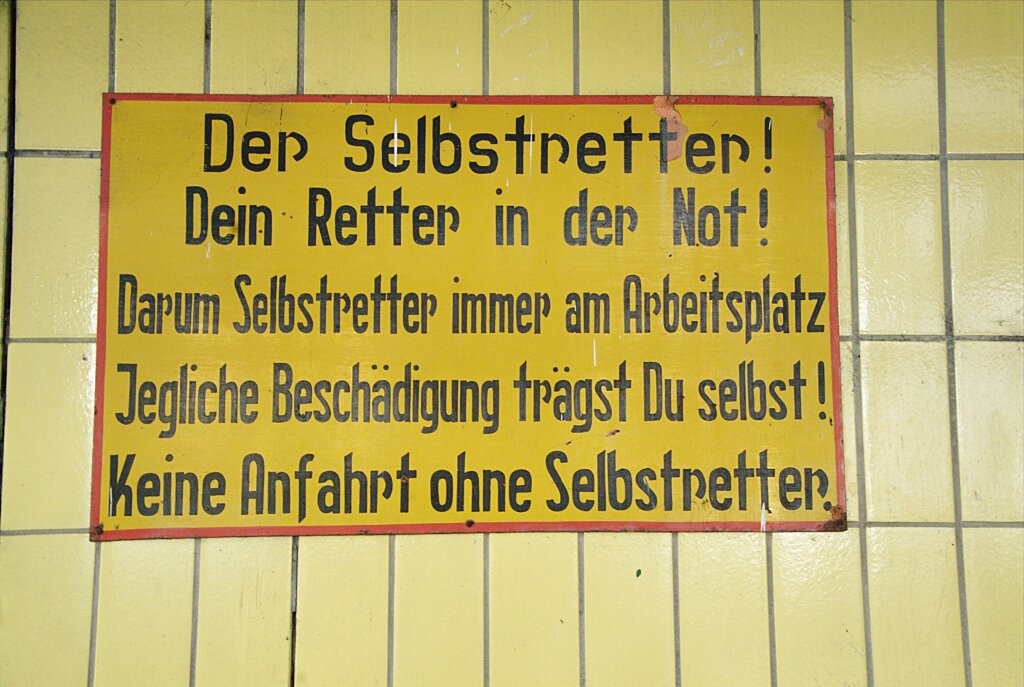

In addition to its contributions to gas lighting technology, the Auer Corporation made significant strides in the realm of safety equipment, particularly for miners. One of the most notable innovations in this regard was the development of the Auer breathing apparatus, also known as the Auer lamp or Auer rescue breathing apparatus.

In the late 19th and early 20th centuries, mining was a dangerous profession, fraught with hazards such as toxic gases and the risk of explosions. Traditional methods of ventilation and safety measures were often insufficient, leading to numerous accidents and fatalities.

To address these challenges, Carl Auer von Welsbach and his team at the Auer Corporation set out to create a breathing apparatus that could provide miners with a reliable source of breathable air in hazardous environments. The result was the Auer breathing apparatus, which utilized chemical reactions to generate oxygen for the user.

The apparatus consisted of a compact canister containing a mixture of chemicals, including potassium superoxide, which reacts with exhaled carbon dioxide to produce oxygen. A mouthpiece connected to the canister allowed the miner to inhale the oxygen-rich air while exhaling carbon dioxide, which then reacted with the chemicals to release more oxygen.

The Auer breathing apparatus represented a significant advancement in mine safety, offering miners a portable and self-contained source of breathable air. It provided protection against toxic gases, smoke, and other airborne hazards, allowing miners to work more safely in challenging conditions.

The Auer breathing apparatus gained widespread adoption in the mining industry and was credited with saving countless lives. Its effectiveness in providing emergency respiratory protection during mine accidents and disasters earned it a reputation as one of the most reliable breathing devices of its time.

While advancements in mine safety technology have continued since the introduction of the Auer breathing apparatus, its legacy as an early pioneer in respiratory protection remains significant. The device stands as a testament to the ingenuity and commitment of Carl Auer von Welsbach and the Auer Corporation to improving workplace safety in hazardous environments.

Following the success of the Auer Corporation in both gas lighting technology and safety equipment like the Auer breathing apparatus, the company underwent various changes and mergers over time, leading to the formation of new entities.

In 1902, the Auer Corporation merged with Deutsche Gold- und Silber-Scheideanstalt (German Gold and Silver Refinery) to form the Auer Gesellschaft. This merger brought together Welsbach’s expertise in gas lighting and safety equipment with Deutsche Gold- und Silber-Scheideanstalt’s resources and capabilities in precious metals refining and chemical manufacturing.

Subsequently, in 1921, Auer Gesellschaft merged with the Degussa company to become Auer-Gesellschaft m.b.H. (Degussa), often referred to simply as Auer Degussa. Degussa was a leading German chemical company known for its expertise in precious metals refining, specialty chemicals, and pharmaceuticals.

This merger expanded the scope of Auer Degussa’s operations, combining Welsbach’s innovations with Degussa’s extensive resources and capabilities in chemical manufacturing. The company continued to produce gas mantles, lighting equipment, and safety devices, while also diversifying into other areas of chemistry and materials science.

One notable development during this period was the further advancement of safety equipment, including respiratory protection devices. Auer Degussa continued to refine and improve upon the Auer breathing apparatus, incorporating new materials and technologies to enhance its performance and usability.

In 1914, Mine Safety Appliances Company (MSA) was founded in the United States by John T. Ryan Sr. and George H. Deike. MSA specialized in the development and manufacturing of safety equipment for various industries, including mining, construction, and firefighting.

While Auer Degussa focused primarily on the European market, MSA became a prominent player in the American safety equipment industry. Over time, both companies made significant contributions to workplace safety, with Auer Degussa continuing to innovate in respiratory protection and MSA expanding its product offerings to include a wide range of safety devices and protective gear.

In 1997, Mine Safety Appliances Company rebranded itself as MSA Safety Incorporated, reflecting its broader focus on providing comprehensive safety solutions beyond just mining. Despite operating independently, both Auer Degussa and MSA have left a lasting legacy in the field of workplace safety, with their contributions shaping the development of safety standards and technologies worldwide.

The relationship between Degussa and the Nazi regime during the period of Nazi rule in Germany (1933–1945) is complex and controversial. Degussa, like many other German companies, became deeply involved in the economy of the Third Reich, and its activities intersected with various aspects of Nazi policies, including the exploitation of forced labor and the production of materials crucial to the war effort.

During the Nazi era, Degussa was involved in several key industries that were essential to the regime’s goals. These included the production of chemicals, metals, and materials used in manufacturing and military applications. One of the most notorious involvements of Degussa during this time was its role in the production of Zyklon B, a cyanide-based pesticide used in Nazi concentration camps for the mass murder of millions of people, primarily Jews.

Additionally, Degussa was involved in the extraction and processing of precious metals, which were often looted from victims of the Holocaust. Degussa’s refinery in Frankfurt processed gold taken from individuals and countries occupied by Nazi Germany, including gold confiscated from Jewish victims.

Furthermore, like many other German companies, Degussa employed forced labor during World War II. Thousands of forced laborers, including prisoners of war and concentration camp inmates, were compelled to work under harsh conditions in Degussa facilities.

After the war, Degussa faced scrutiny for its activities during the Nazi era. The company was implicated in war crimes and complicity with the Nazi regime, particularly regarding its involvement in the Holocaust and its exploitation of forced labor. However, like many German companies, Degussa underwent various transformations in the post-war period.

In the decades following World War II, Degussa sought to distance itself from its Nazi-era past and underwent significant restructuring and rebranding. The company diversified its operations and focused on new areas of business, including chemicals, materials, and specialty products.

In 1980, Degussa AG was officially established as an independent entity following a merger between DEutsche Gold- Und Silber-Scheide Anstalt (Degussa) and other companies. The company continued to evolve and expand its operations on an international scale, eventually becoming one of the world’s leading specialty chemical companies.

Despite its efforts to move forward, Degussa’s Nazi-era history continues to cast a shadow over its legacy. The company has faced criticism and legal action related to its wartime activities, including lawsuits filed by Holocaust survivors and their descendants seeking restitution for forced labor and other injustices. Through various initiatives, Degussa has acknowledged its historical responsibility and worked to address the consequences of its actions during the Nazi era.

Carl Auer von Welsbach

Carl Auer von Welsbach, the Austrian chemist and inventor, made significant contributions to the study and understanding of rare earth elements, including praseodymium, neodymium, and lutetium. While Welsbach was not directly involved in the discovery of lutetium, his work was influential in the broader context of rare earth element research.

Praseodymium and Neodymium: In 1885, Carl Auer von Welsbach isolated praseodymium and neodymium while conducting experiments on rare earth elements. Through his research, Welsbach identified these elements as distinct components of a mixture of rare earth oxides. His discovery of praseodymium and neodymium contributed to the growing understanding of the rare earth group and their properties.

Welsbach’s work on praseodymium and neodymium was particularly significant due to the unique spectroscopic properties exhibited by these elements. These properties played a crucial role in various applications, including the development of improved lighting technology and other industrial processes.

Lutetium: Although Carl Auer von Welsbach did not directly discover lutetium, his research laid the groundwork for its eventual identification. Lutetium was independently discovered by Georges Urbain, a French chemist, and Welsbach himself, in 1907. Urbain isolated lutetium from ytterbium oxide residues, while Welsbach discovered it as a component of ytterbium ores.

Welsbach’s contributions to the discovery of lutetium underscored his continued involvement in the study of rare earth elements. His work helped expand the known scope of rare earth elements and their applications in science and industry.

Overall, Carl Auer von Welsbach’s research on rare earth elements, including his discoveries of praseodymium and neodymium, as well as his involvement in the identification of lutetium, played a significant role in advancing our understanding of these elements and their practical applications. Welsbach’s contributions continue to be recognized for their importance in the field of chemistry and materials science.

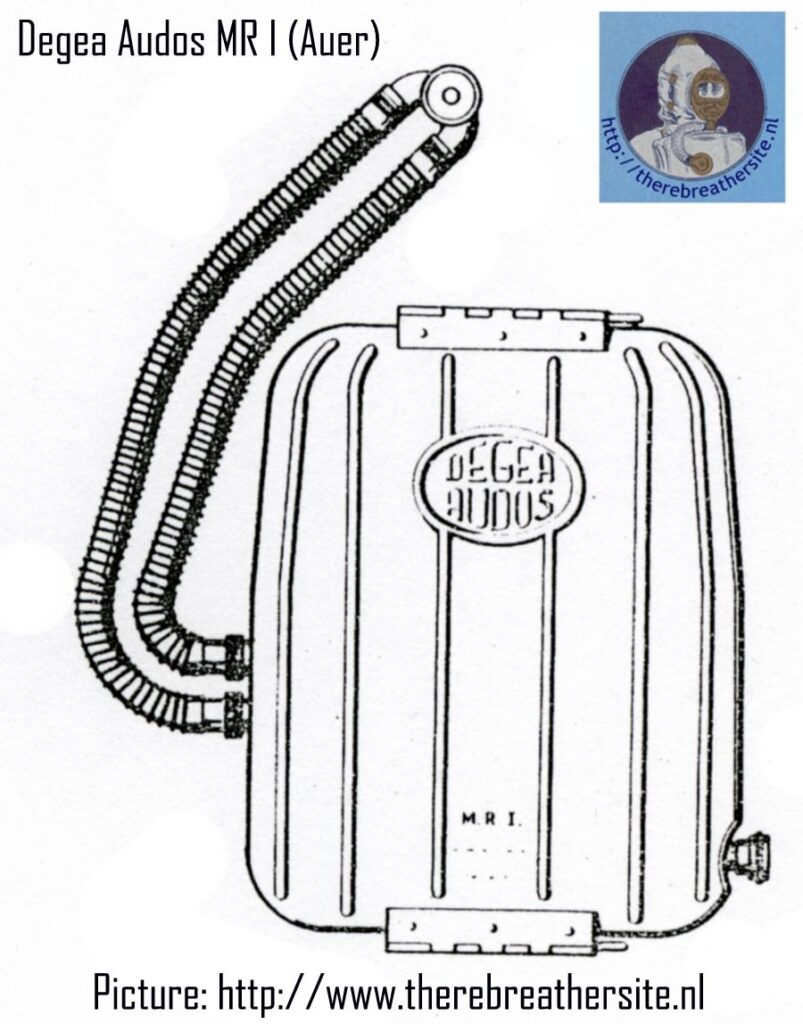

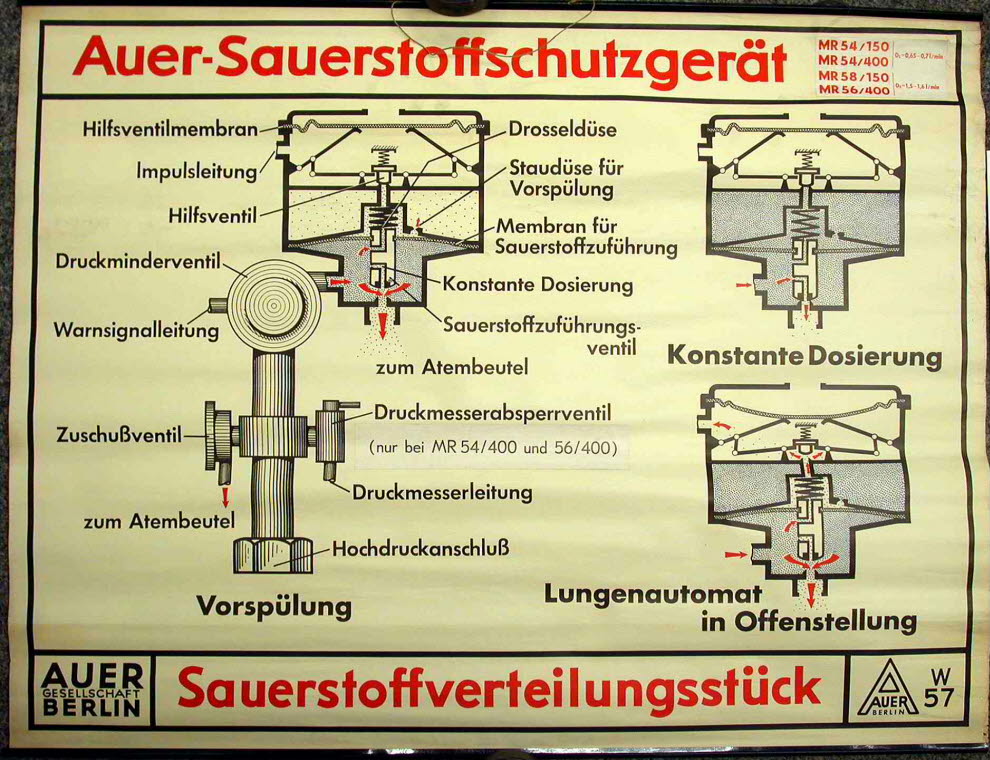

The Auer Gesellschaft Breathing Apparatus 54/400, also known simply as the Auer 54/400, was a remarkable respiratory protection device developed by the Auer Gesellschaft, founded by Carl Auer von Welsbach. This apparatus marked a significant advancement in mine safety and industrial respiratory protection during the early to mid-20th century.

The Auer 54/400 was designed to provide miners and industrial workers with a portable and self-contained source of breathable oxygen in hazardous environments. It featured several essential components:

Oxygen Cylinder: The apparatus included a robust oxygen cylinder storing compressed oxygen under pressure. This cylinder served as the primary source of breathable oxygen for the user.

Lung Operated Mechanism: Instead of a pressure regulator, the Auer 54/400 utilized a lung-operated mechanism. This mechanism allowed the user’s inhalation and exhalation to control the flow of oxygen. When the user inhaled, the decrease in pressure within the breathing bag triggered the release of oxygen. Conversely, when the user exhaled, the increase in pressure closed off the oxygen flow, preventing wastage.

Breathing Bag: A flexible breathing bag, typically crafted from durable materials like rubber or canvas, was integrated to store the compressed oxygen. The bag served as a reservoir of oxygen that the user could draw upon as needed.

Mouthpiece: Equipped with a mouthpiece connected to the breathing bag, the Auer 54/400 enabled the user to inhale oxygen from the bag and exhale into the surrounding environment. The mouthpiece was designed for comfort and security, ensuring a tight seal to prevent oxygen leakage.

Harness System: To facilitate wearing and carrying the apparatus, an adjustable harness system with straps and buckles was included. This system allowed the device to be worn securely on the user’s body, leaving their hands free for work tasks.

The Auer Gesellschaft Breathing Apparatus 54/400 played a vital role in enhancing workplace safety in industries such as mining, construction, and firefighting. By providing workers with a reliable means of respiratory protection through a portable oxygen supply, the apparatus helped prevent accidents, injuries, and fatalities caused by exposure to toxic gases, smoke, and other airborne hazards.

Though the Auer 54/400 is no longer in widespread use today, its legacy endures as a testament to the ingenuity and innovation of Carl Auer von Welsbach and the Auer Gesellschaft in developing life-saving safety equipment for industrial workers.

The Auer Gesellschaft made many types of breathing apparatus during its existence.Models known were the Selbstretter 16B and the more modern SSR 30/100 and SSR 90 (K60). the Airelite KO2 and earlier types 54/150, 54/400, 56/150, 65/400 and the 58/150 and 58/400. The latter series was produced in the 1950s and had widespread use in the European mining industry.

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!