Brent build a reliable MCCR rebreather from a Dolphin rebreather

| First things first, there are no electronics on this page. They have been removed for the pictures as they are part of a new product. You will all get to see them one day!I’ve been diving this unit for at least a year now, this current form is a recent development. Originally it was fitted with a Swagelok SS2 metering valve, some heavy wave action and a heavy rebreather put that in the broken bits box.I remember my first dive on this and I was scared to death. I just couldn’t keep my eyes off the instruments, I was convinced it would try to get me, and I suppose that is what kept me sane when homebuilding. A healthy knowledge and respect for a rebreather is essential survival kit, even on factory built units. After some time, I realised it wasn’t trying to kill me, but if I wasn’t careful it was a likely outcome. Skill and practice and experience are all very good defenses against many problems.Some say I am lucky that I haven’t had too many problems, I say “the more I practice, the luckier I get!”. Despite the ‘voodoo magic’ like aura that surrounds rebreathers, they are really simple devices. This rebreather is as simple as they come, based upon the mass produced Drager Dolphin semi closed rebreather, it was an easy task to make it fully closed. |

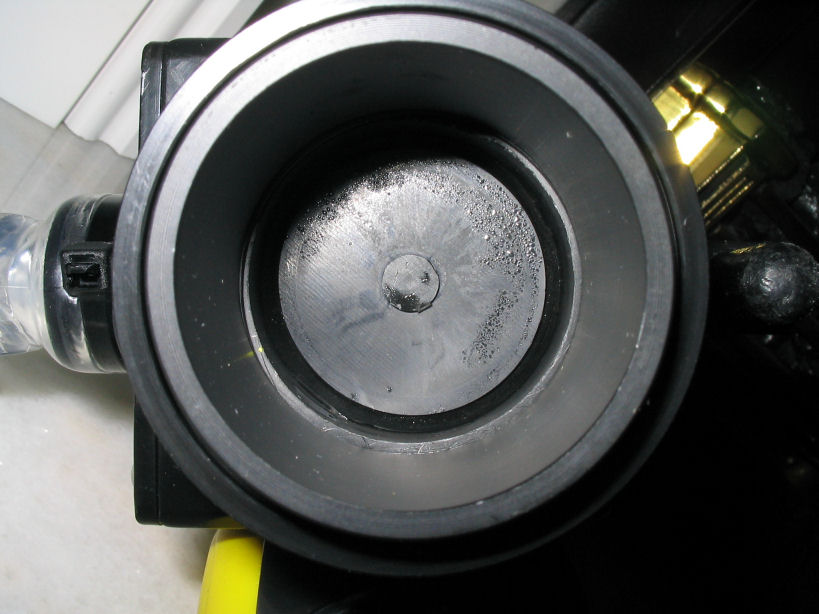

Here is the front. It is a Drager Dolphin which has been stripped down and refitted with parts I like better.

A brief run down;

On the left is the Poseidon Xstream connected to the O2. The reg on the right is on a 2m hose to the 5ltr bail out cylinder.

The wing is a Zeagle which has all the plumbing and pipe work running internally in the cloth.

O2 addition is via a Hydrogom valve with all Swagelok fittings. The usual DS4 feeding a fixed IP to the magic push button.

(This used to be a Swagelok micrometric metering valve with a variable IP first stage until I broke it.)

The Bob Howell OC/DSV is connected to the Dil cylinder via a flow stop. The Bob is actually made for an Inspiration, but more of the adaptors later on.

Hopefully more of it makes sense when you see the rear. Bail out on the bottom is not Oxygen, just the label has not been changed to Nitrox (tut, tut, I know, I know). The adaptors on the 5ltr are temporary, I have a more direct adaptor being fixed. Dil on the left, oxy on the right.

The problems that needed to be solved to change this semi closed into a closed circuit rebreather are all simple ones which need a bit of thought. Broken down simply;

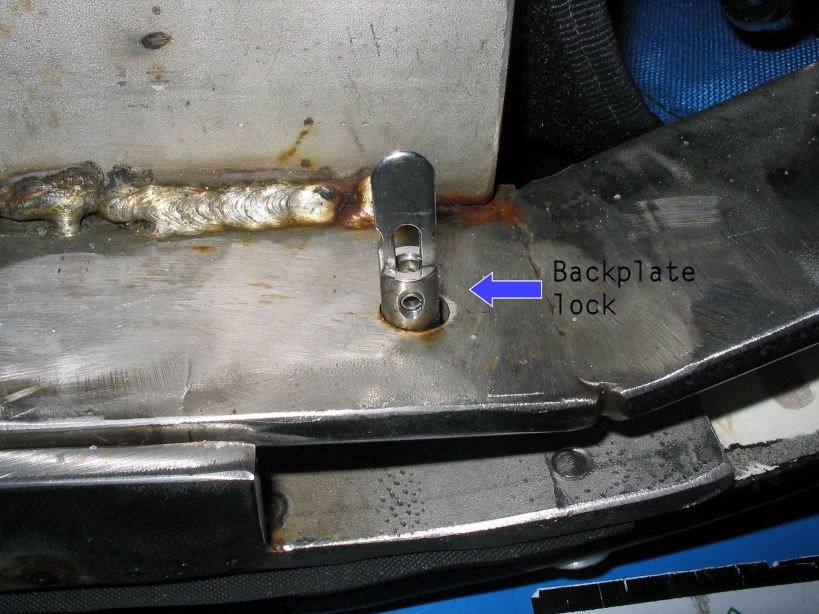

The tidal volume available in the standard Drager was insufficient for an easy work of breathing and efficient use of gas, so a backplate arrangement was made that lifts the shell of the rebreather away from my back by an additional 35-40mm to allow for a full lung exchange with the rebreather. The backplate is locked onto the shell with these lock tags I made. Fast and secure. The weight is held by the dog in the centre foreground.

Here’s a close up of the retainer and my shity stainless welding.

The other half, make sense?

The main difference between the semi closed and the closed is that the closed circuit does not want to bleed gas out of the lungs to work. The over pressure valve (OPV) was modified to allow a closed position with a high static lift pressure to prevent loop losses. This means that before the lungs will burst the valve will give, but loop volume control is more a manual task than automatic by the OPV.

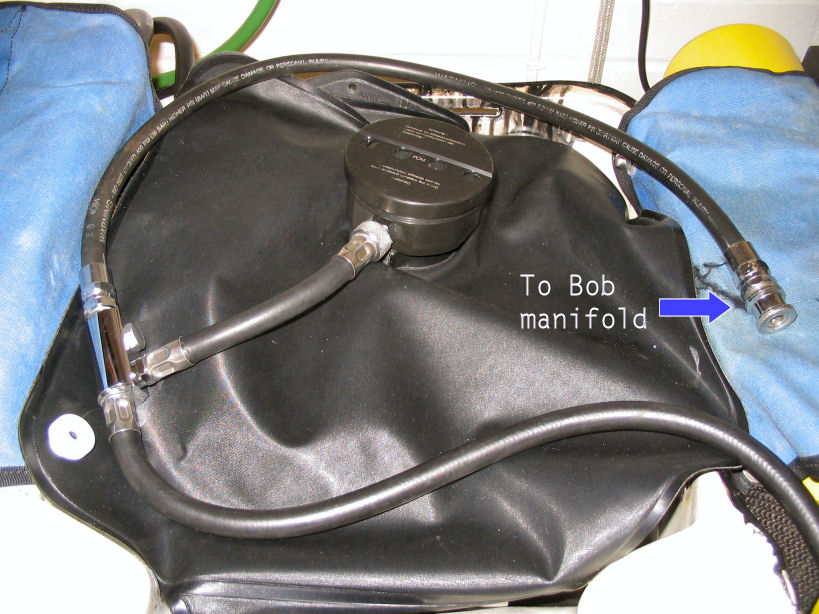

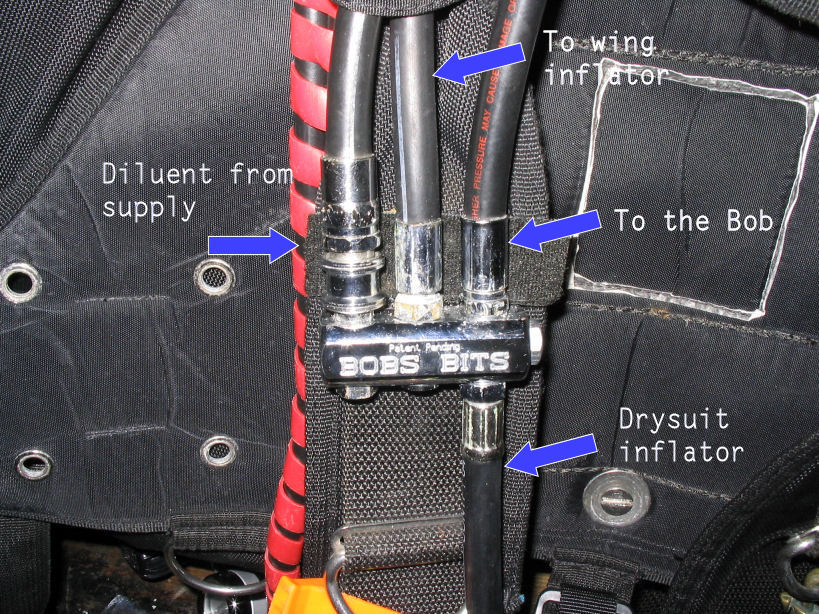

Diluent is fed from an Xstream 1st stage to a primary manifold which splits the feed for the Ray ADV (with no orafice) and to the schrader fitting. The schrader fitting connects to the secondary diluent manifold on the front right chest strap.

Hopefully this is self explanatory. This system keeps all the main hoses fitted inside the cordura nylon of the wings structure except the Bob feed hose and 6″ dry suit inflator.

Oxygen addition is via a contsant mass flow orifice (CMF) valve supplied by Hydrogom in Holland

(write up here -> http://www.therebreathersite.nl/01_Informative/hydrogom_cmf_valve.htm).

This is a brute of a valve which weighs a ton! As the human body uses oxygen at a known rate, this valve feeds a little below this rate allowing a manual top-up at suitable intervals. Having run my unit as a semi closed for some time, I was acutely aware of my own metabolic rate of consumption by using a calculator available here – http://homepage.ntlworld.com/brent.h/information/rebreather/O2_Metabolism_Calculator.xls

An Apex DS4 1st stage is used as it is so well proven by my predecessors. The actual rate of delivery of the oxygen is regulated by

rotating a hex key in the first stage under the dry sealed cap, a flow meter is used to check its flow is within the design limits. In order for the DS4 to be used with a CMF valve the dynamic depth compensation must be disabled. this is achieved by making a blanking disc which fits inside the first stage to prevent any ambient compensation. (Blanking disc provided by John Routley Narked@90 – thanks mate!)

And then feeds into the exhale side of the scrubber with a schrader valve. Parts from Tecme.

The scrubber actually has a nice 3mm fitted neoprene jacket I made for it with Velcro fastening. Does it help? Who knows, cant do any harm to maintain the temperature as much as possible.

An original Bob Howell OC/DSV. Breath it in boys, feel the envy! Shown on closed circuit mode.

The Bob was actually made for an Inspiration and has been adapted to fit the Dolphin EPDM breathing loop. The connectors were made by Filip from Nemotech. I have been unable to contact Filip to show my gratitude for the good work he has done.

Hopefully he will read this.

And the back. Nuff said, lets see the adaptors.

Well that’s overview for those who ever wondered. Big pictures may take some time to load, but they are easier to see my box ‘o’ bits.

email brent)AT(divetheworld.org.uk

Well Brent, that was a nice article! Although the welding can be improved (;)) I think there are some nice ideas in the unit. I am looking forward for your update about the electronics! The moment you finished that part of the project I would like to publish it here! Thanks, Janwillem.

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!