Before the Undersea Technologies UT-240 Oceanic announced the Phibian

Oceanic is an American manufacturer of scuba gear. It was founded by Bob Hollis in 1972 and is based in San Leandro, California, United States. Its products include dive computers, rebreathers and a novel diving mask incorporating a heads-up-display of information.

In 1972, Robert Hollis founded the parent company American Underwater Products which did business as Oceanic. In 2017, Huish Outdoors acquired the Oceanic and Hollis brands from AUP.

They developed the Phibian CCS50 and CCS100 rebreathers; Stuart Clough of Carmellan Research Ltd in the UK developed the Phibian’s electronics package. With its purpose-built training facility, Oceanic UK working closely with American Divers International, developed and delivered by both Stuart Clough and Paul Morrall training and familiarisation courses.

They have developed military rebreathers for use by frogmen and naval work divers, for example the US Navy MK-25 and the MK-16 mixed-gas rebreather.

Oceanic build and planned selling the Phibian rebreather.

Oceanic stops the project and Stuart develops the Phibian into the UT240. There was a lawsuit and Oceanic were restricted to making only SCR units for a period after the lawsuit. UT= undersea technology related to Carmellan Research UK.

Besides the UT240, the UT180 and the UT90 (never seen a pic from the last two) also exist.

The UT240 was the first rebreather with a CO2 sensor and a dual temp stick in the scrubber.

The unit was later used exclusively for military purposes and in tests at NASA.

Eight units of the UT240 were produced (?).

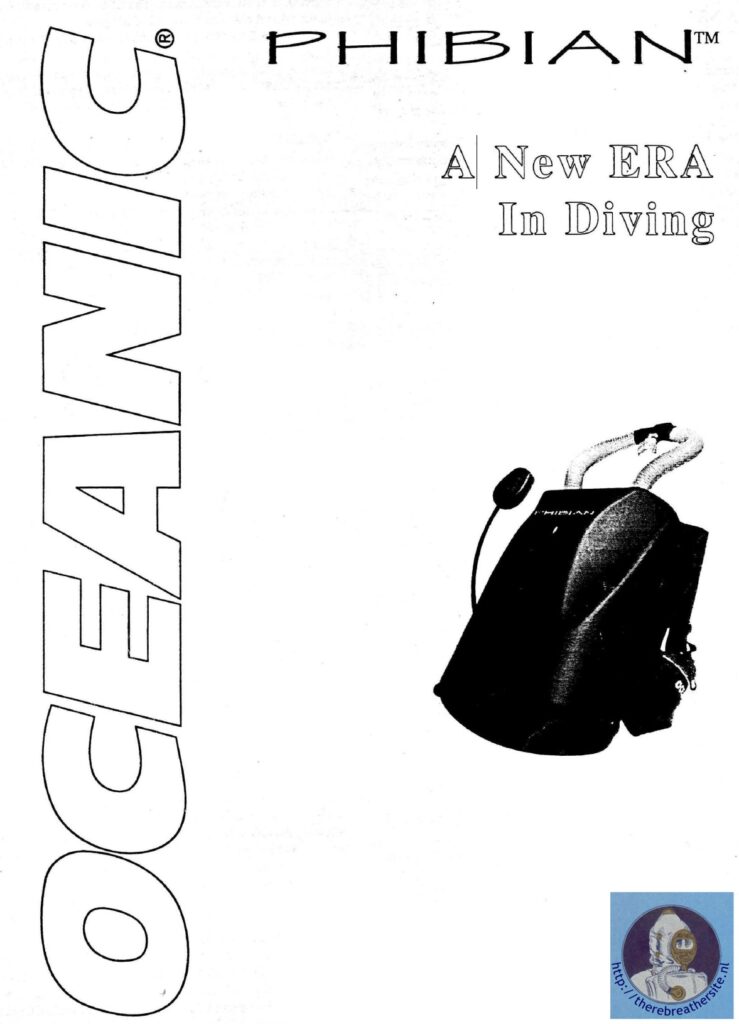

A NEW ERA

Oceanic, is pleased to introduce the Phibian CCS 50 and CSS 100. These two state-of-the art closed circuit SCUBA systems, IO years in development, are bound to mark the beginning of a new and exciting era for diving. The Phibian will enable divers to dive deeper and to stay longer, yet avoid the extremely long decompression stop times normally associated with these types of dive profiles. Phibian’s elimination of exhaust bubbles will allow a diver to observe or photograph a world of incredible beauty filled with amazing occupants no longer frightened away by the noise of roaring exhaust bubbles. Not just will the casual weekend diver benefit from the above, but also will the explorers, wreckers, cavers, resorts and live aboard operations. And we designed the Phibian CCS 50 from the start to make it easy and very friendly for today’s recreational diver to learn and operate, so they can spend their time underwater enjoying the environment and not be constantly worrying about a lot of complex facts and figures. Thanks to reliable microprocessor based electronics and user friendly software that has touched us in so many areas of our modem life, a certified diver can be taught to operate the Phibian CCS 50 with 40 hours of instruction and four supervised open water dives.

OPEN CIRCUIT SCUBA

The Phibian CSS is quite different than traditional open circuit SCUBA in which a diver employs a cylinder of compressed gas and a regulator that reduces tank pressure to an intermediate level and allows it to pass to the diver on demand. The diver then exhales, releasing air into the water in the form of bubbles. This process is very inefficient as only a small portion of the life giving oxygen content of the breathing gas is actually metabolised by the diver. The unused portion together with the accompanying gas is lost with each breath.

CLOSED CIRCUIT SCUBA

Closed circuit systems basically enable the diver to retain and reuse some or all of his expired gas. This expired gas is reprocessed to remove carbon dioxide, with oxygen and diluent gas added on a controlled basis to replace that which has been metabolically consumed, with the diluent providing volumetric makeup.

THE PHIBIAN CCS COMPUTERISED GAS BLENDING SYSTEM

The most advanced and appealing feature of the Phibian is its patented computerised gas blending system. During each breathing cycle the electronic computer system analyses the oxygen content of the breathing mixture and adds the correct amount of oxygen necessary to maintain the diver’s required partial pressure of oxygen at any particular depth and at any given workload. Furthermore, this onboard computer has the capability to decrease the diluent gas and increase the level of oxygen during any required decompression, thereby dramatically reducing the diver’s stop time that would have otherwise been required by more conventional closed circuit systems.

PHIBIAN CSS SO AND CSS 100

The Phibian CSS 50 Nitrox system, (operationally rated to 50 meters), is a two bottle system. The CSS 50 uses compressed air in the diluent bottle and a bottle of oxygen. The Phibian CSS 100, (operationally rated at 100 meters), is a mixed gas unit capable of using a variety of diluent mixed, such as Nitrox, Heliox and Neon-oxygen, coupled with an oxygen bottle. The CSS-100 unit is a four bottle configuration. Both units are self contained, back mounted, and have dual breathing bags. NITROX It has long .been recognized that atmospheric air contains 21 % oxygen and is far from ideal for most diving applications. In recent years the practice of using mixtures containing-higher levels of oxygen (for example Nitrox 32%, Nitrox 36% and Nitrox 40%), has grown significantly in both the scientific and recreational dive community. While these mixtures are better than air in terms of the resulting no-decompression time available to the diver, they are also depth limited. For example Nitrox 36% would normally not be used below 100 feet and Nitrox 32% would not be used deeper than 130%. With the Phibian CSS 50, the diver’s concern over the right mixture of oxygen and nitrogen are eliminated because of out computerised gas blending system. With oxygen in one cylinder, and compressed air in the diluent cylinder, the Phibian automatically and constantly releases the correct amount of gas from each cylinder into the system to ensure that the breathing mixture is optimal throughout the dive.

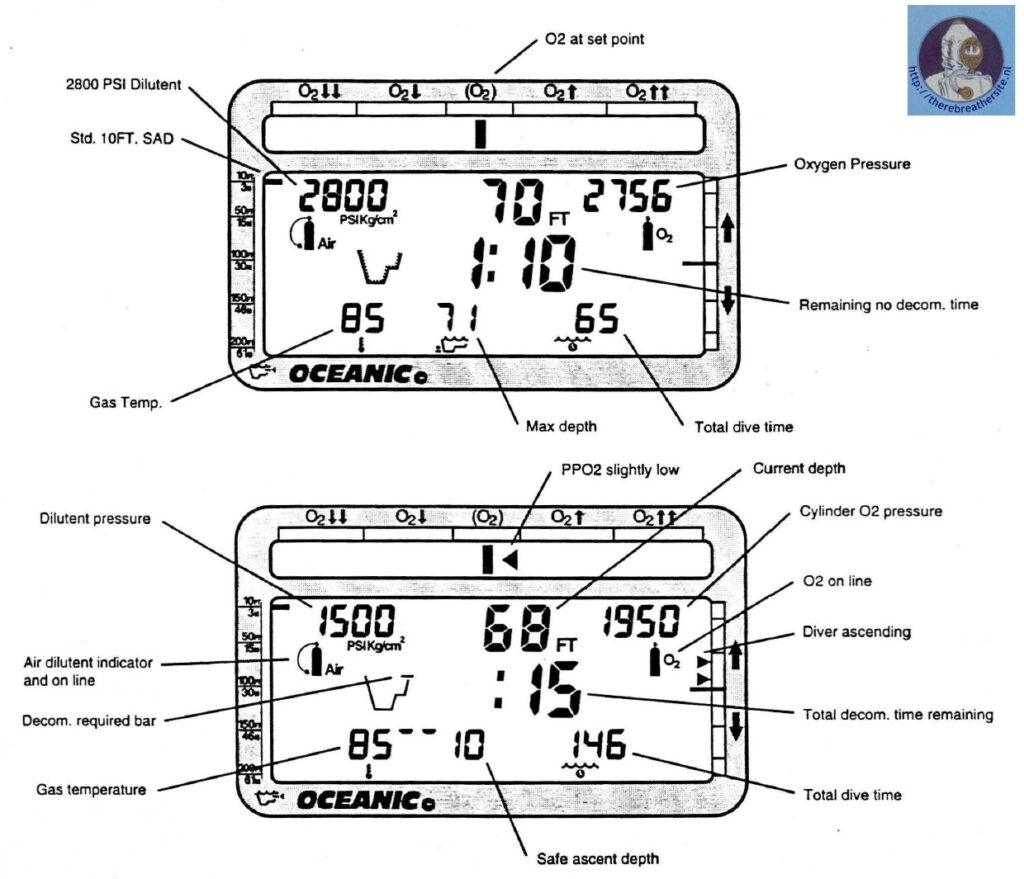

DIGITAL DIVER CONSOLE

The Phibian electronic control system monitors diluent tank pressure, oxygen tank pressure, depth, time at depth, no decompression time remaining at an particular depth dependent upon the diluent gas used, accent rate, decent rate, current ceiling, total decompression time required, total decompression time at ceiling, water temperature, gas temperature, rate of gas usage on both diluent and oxygen bottles, type of inert gas, oxygen partial pressure status, sensor condition, and various warning conditions. This information is presented to the Phibian user in the graphic diver console which is attached via an umbilical cable to the CPU in the electronic control system.

REDUNDANT SYSTEM

Redundancy in as important part of the Phibian systems. All units feature LCD display readouts and warnings that show if the oxygen injection system is working properly. Easily accessible manual bypass valves are provided for both the diluent and oxygen systems to add gases manually if necessary. Additionally, a second stage regulator is attached to the diluent first stage valve, allowing the unit to be used as an open circuit system in an emergency. Redundant Oxygen sensors and optional carbon dioxide sen~ors add increased reliability during decompression diving. OptJonal features for commercial divers allow the use of Phibian’s with umbilical gas support and bailout systems.

TRAINING AND SALES

Training in the use of Phibians for both end users and instructors will be available through a new training organisation, rrr, International Training and Technology. Sales and service of Phibians will be provided by an exclusive worldwide network of Oceanic/ Phibian dealers.

Phibian Rebreather part II

Source: http://www.ukdiving.co.uk/equipment/articles/phibian.htm

TAKE YOUR BREATH AWAY

In preparation for the much awaited retail launch of the Phibian rebreather, Oceanic has launched training and familiarisation courses at its Honiton, Devon, headquarters. The course is presented by Stuart Clough of Carmellan Research Ltd in the UK who developed the electronics package for the Phibian for Oceanic and uses pre-production protypes.

Most divers have heard of the benefits of rebreathers – longer bottom times and shorter decompression penalties. But many are put off by the perceived complexities and the cost.

The seminar explains the history and the concept of rebreather technology and describes the benefits of reclaiming and recycling the oxygen in the gas mix and adding fresh oxygen as required. It is at this stage that the course participants really begin to sit up and take notice, whether their interest in technical diving, cave diving, or marine biology, as the comparative bottom times, gas consumption and decompression requirements are unravelled before you.

For example a standard air dive to 40m for a theoretical 60 minutes would mean 118 minutes of decompression. The same dive using the Phibian rebreather would mean 46mins decompression time.

The Phibian system can be specified for use up to 50m depth in which the diluent gas will be compressed air, or for deeper ‘technical’ diving in which the diluent gas will be Heliox or another suitable inert gas mixture. In both specifications none of the expired gas mixture is lost from the system but is recycled, scrubbed and enriched with oxygen as necessary.

There follows a detailed description of the way that the hardware and electronics software functions. This is all displayed using computer generated graphics and animated diagrams which are very easy to follow no matter how rusty your recollection of diving physics and physiology.

There were two pre-production prototype units available for trial at the time of my visit – a closed circuit, pure oxygen re-breather and the Phibian CCS50 designed for air range diving using oxygen at a constant partial pressure with compressed air as the diluent gas. Monitoring, mixing and delivery of the breathing gas in the CCS50 is controlled by the electronics package which has an integral dive computer, while the oxygen rebreather is an entirely manual unit which provided an interesting contrast.

The mixed gas model, the CCS100, is similar to the CCS50 with the exception of breathing gas and computation requirements. All of the Phibian’s hardware is contained in a moulded casing with a waistcoat BC attached. Buoyancy compensation and bale out are provided by the diluent gas cylinder using a standard demand valve and low pressure inflator assembly.

The first step is to accustom yourself to the breathing characteristics of the unit on the surface and to be reminded that the mouthpiece valve must be closed if it is removed from your mouth for any reason.

Initially you are required to trim the counter-lungs to your breathing rate and lung volume on the surface. This is achieved by bleeding off or injecting diluent gas into the system until the inhalation and exhalation effort is comfortable. This is followed by a slow descent down a shot line in the centre of the tank to its maximum depth of 10m. As you descend the increase in water pressure progressively collapses the counter-lung and you must manually increase the volume of diluent gas in the lung until breathing is comfortable.

The first impression is, of course, the total lack of bubbles and almost silent operation, except for the reassuring click of the solenoid on the oxygen injection valve. Unlike a conventional demand system there is no positive pressure delivery as you are breathing the gas at ambient pressure. Breathing in and out has no effect on your buoyancy, for the same reasons ,and it is not until you begin to ascend that your buoyancy changes as the volume of the gas in the counter-lung expands. On the current prototypes this expanding gas is vented either by breathing out through your nose or the corner of your mouth , however production models will be fitted with pressure relief valves to eliminate this requirement. Ascending and descending a few times soon makes you comfortable with the basic operation of the system and lets you concentrate more on this strange and exciting experience.

One or two drawbacks of the current prototypes were apparent. The bulk of the enclosed unit would make swimming difficult in current or a shallow swell and similarly the size and buoyancy of the hoses restrict head movement (although we were informed that production units will be trimmed down in both these areas). Also, because the counter lung is on your back, if you roll over you find a noticeable increase in breathing resistance due to the increase in hydrostatic pressure. The Phibian will cost between £5-10,000 dependant on specification.

Oceanic suggests that interested technical divers should start with the familiarisation day and then perhaps take a more comprehensive course, tailored to their intended use, with further extended and open water practical sessions.

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!