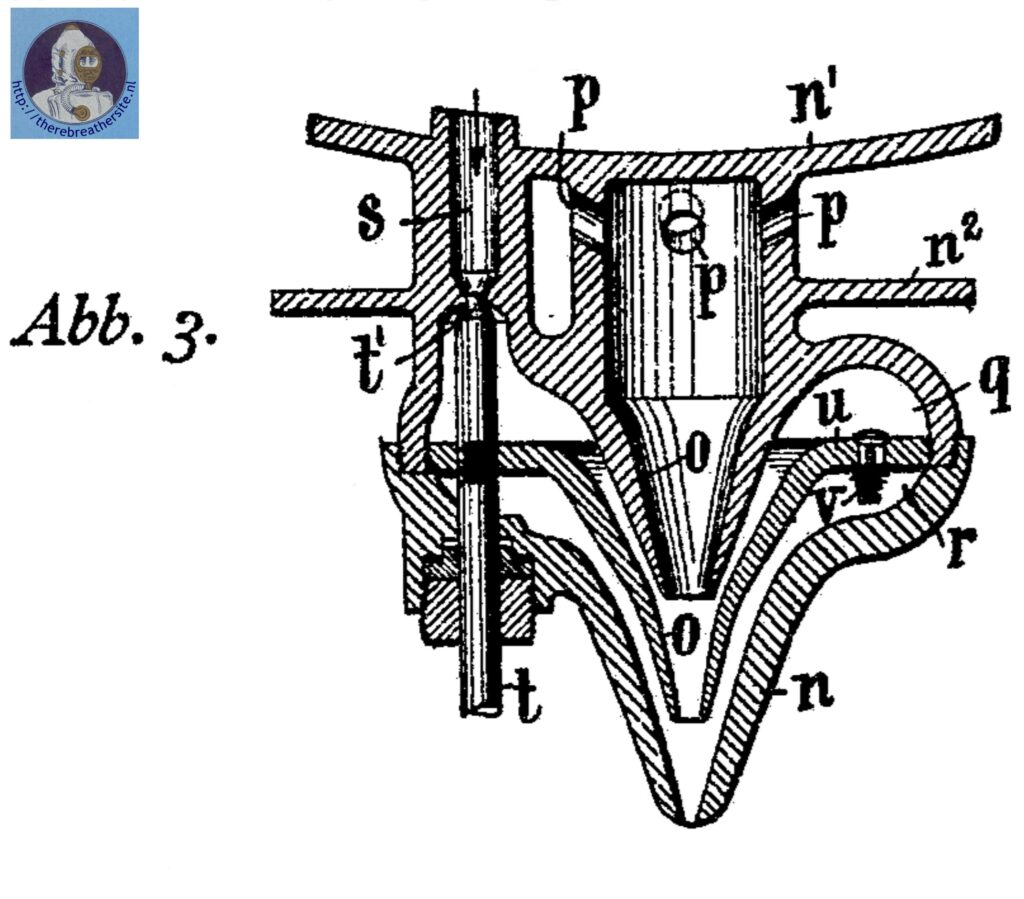

Carlitscheck and Zander designed a system whereby the exhaled air of the diver could be brought outside the suit through an ejector system. This eliminated the return hose that had to be run from the suit to the surface to remove the exhaled atmospheric air.

Diving armour with walls absorbing the external water pressure. Diving deeper than with diving suits, to which the diving air is supplied at a pressure corresponding to the water depth, can be achieved with diving suits which are designed in a tank-like manner to absorb the external water pressure and allow the introduction of air at atmospheric pressure, so that the diver can work in normal air regardless of the water depth. These diving tanks are made of pressure-resistant mesh with a flexible coating at the points which must be movable. For depths of about more than 3 3 in, only such diving tanks can be considered, because the increasing air pressure causes increasing discomfort for the diver. With these armoured divers, the removal of the used breathing air by means of a special hose causes difficulties which, according to the invention, are to be avoided by avoiding a hose.

For the removal of the used air, the diving tank is therefore provided with a blow-off valve operated with compressed air, which is designed as an ejector and enables the removal of the air used by the diver from the inside of the tank without a hose line. The blow-off valve can be fed from the compressed air line, from which the air is introduced into the diving tank via a pressure-reducing valve in order to reduce it to atmospheric pressure.

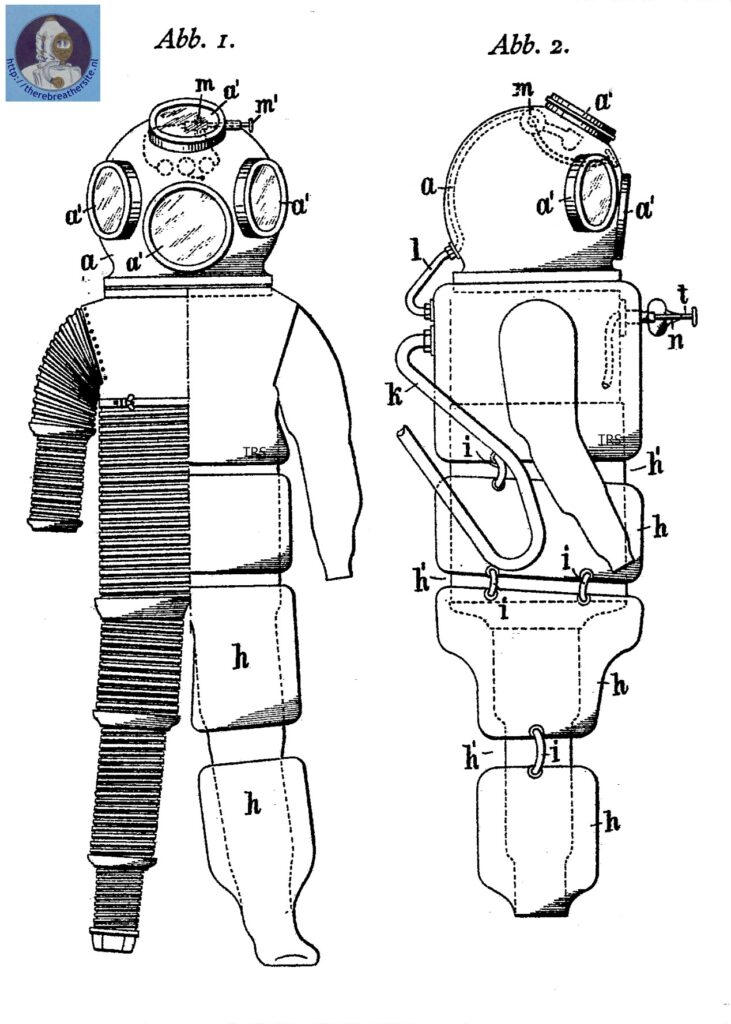

The drawing shows an example of the invention, Fig. 1. front view and Fig 2 side view of the whole tank, Fig. 3 horizontal section through the ejector.

As usual, the diving tank consists of a head piece a with windows a’ directed to different sides, to which the rest of the tank is connected. The diving armour is surrounded by air cells h, which are interrupted at the joints at h’ in order to allow the diver free movement to carry out the work. The individual cells are connected by hose nozzles i. The air pressure line k connects to one of the cells, e.g. as shown, to the chest cell. Another line L leads from it into the bonnet a to a pressure reducing valve m, whose valve stem m’ is led outwards so that the diver is able to adjust the valve. The compressed air pressure in the cells, which changes according to the diving depth, is reduced to atmospheric pressure by the valve in, so that the compressed air enters the bonnet only at normal pressure and the diver can work under normal breathing conditions. At the front of the chest cell is an ejector n (Fig. 2 and 3), which is sealed with a flange n on the inner suit and with a flange n on the wall of the chest cell h The ejector n. contains nozzles o, from which the compressed air of the cells lt enters via the channels p and blows outwards into the water. Accordingly, the compressed air pressure must always be somewhat higher than the water pressure. The jet of compressed air creates a dilution of air in the chambers q and r of the ejector n and thus extracts the used respiratory air from the inner tank via the channel s. The air is then blown outwards into the water. A spindle t with valve cone t’ led to the outside allows the diver to regulate the amount of air to be extracted. In the intermediate wall u of the two chambers q and r, several spring-loaded valves v are connected, which prevent the creation of too great a vacuum, so that the pressure in the diving tank can never drop significantly below atmospheric pressure.

If necessary, the pressure reducing valve m could operate automatically so that it always opens as soon as the pressure in the diving tank drops below atmospheric pressure, but also does not allow it to rise any higher. For this purpose, the ejector n. could be equipped with a valve connected to the pressure reducing valve, which closes when the pressure in the tank drops below an atmosphere. The communication of the diver with the diving ship can be done in the usual way by rope or bell system or also telephone.

Claims: Diving tank with walls absorbing the external water pressure for maintaining the breathing air at atmospheric pressure, characterised by a blow-off valve (n) for compressed air operation which, as an ejector, sucks the air used by the diver out of the interior of the tank.

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!