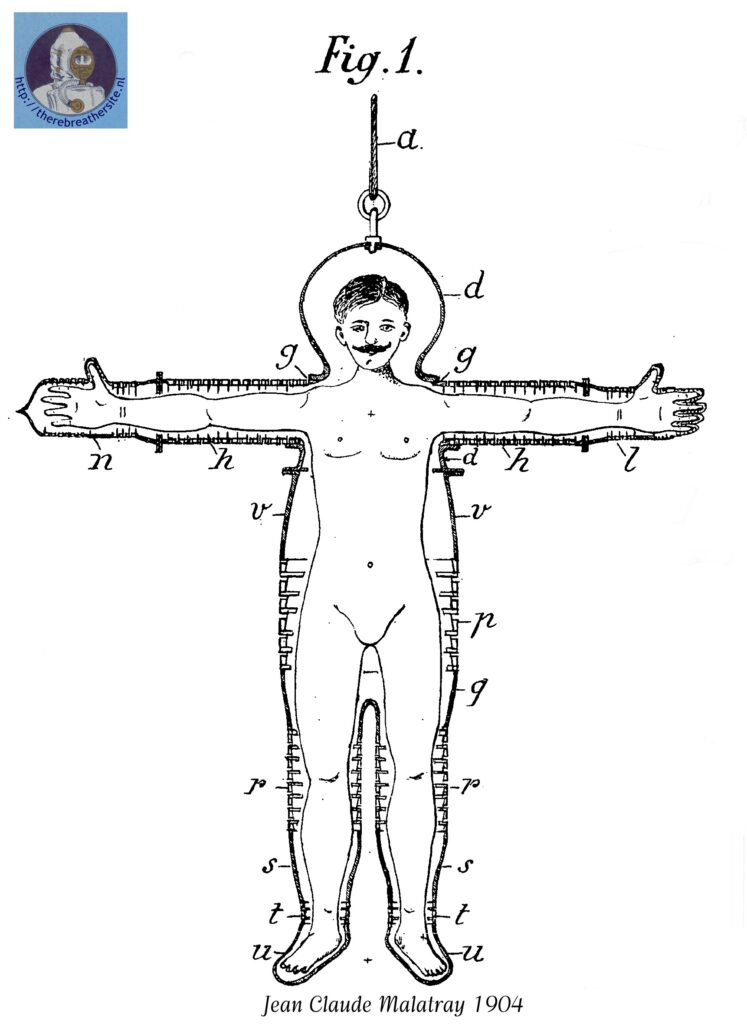

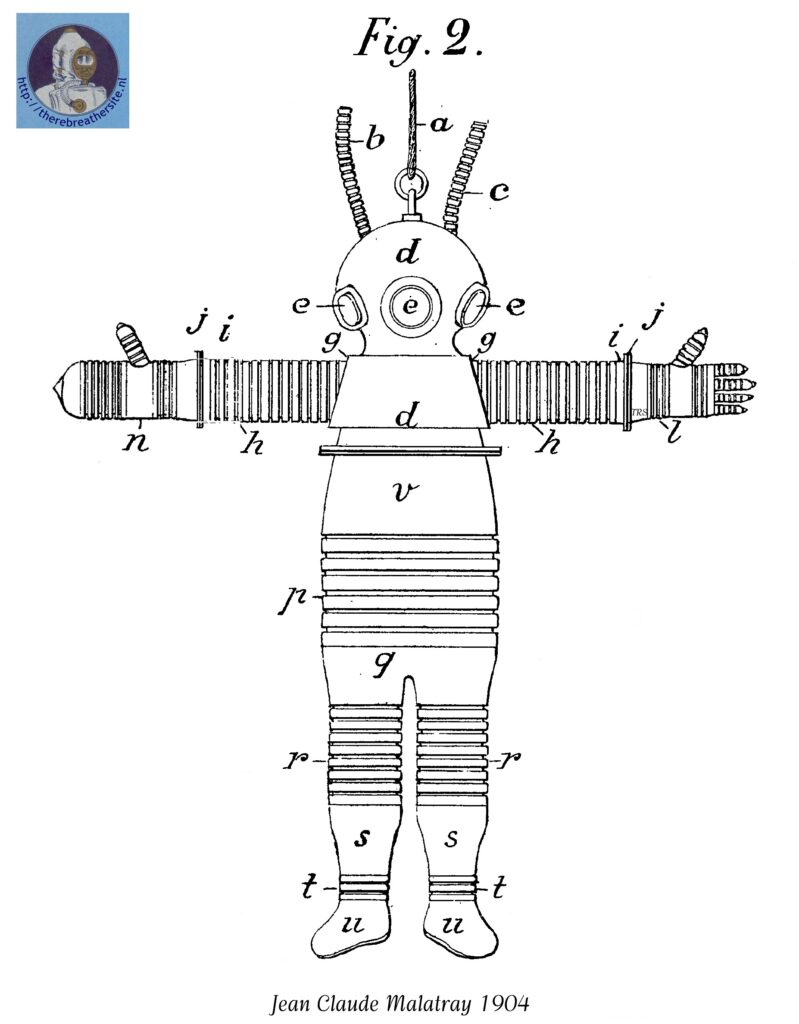

The diving suit covered by the invention enables the diver to descend to very great depths and to carry out the necessary movements. It consists of an all-metal armour which protects all parts of the diver’s body; this armour is made up of certain rigid parts and other parts which are hinged; the latter are made watertight by means of appropriate attachments.

This system allows the diver to descend and move to great depths without danger, under the conditions mentioned below. The round shape generally adopted for the parts of the armour, which is necessary because of the hinge system, has the advantage that the effects of the compression of the metal are more evenly distributed and consequently the thickness of the walls is more regular. In addition to the necessary basic clothing, the diver will receive a garment made of soft leather. The leather will generally be thicker at the places where the friction of the joints occurs. A leather glove will cover the hands. Each part of the harness must have the internal dimensions required for the diver’s torso and limbs. To facilitate the joints, where there are hollows. The weight of the diving suit must be kept to a minimum. The weight of the suit should be greater than the weight of the volume of water displaced, with an amount equal to the weight of the ballast needed to keep it on the bottom, because if it were heavier, the diver would be too heavily loaded to change position easily. The maximum depth that the diver will be able to reach under these conditions can be determined by making the diver’s suit, constructed according to the theoretical calculations of resistance, descend, after weighing it, only to a depth much greater than that on which these calculations are based. If we want to descend significantly lower, we will need a suit with thicker walls and this will result in an increase in weight, which will impede the diver’s progress.

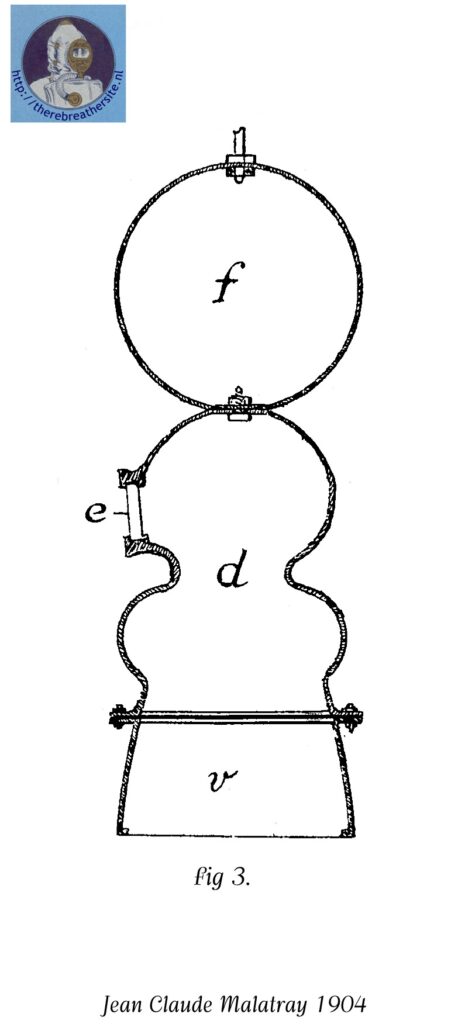

To overcome this inconvenience, the diving suit is equipped with a spherical compensating hydrostatic device, which is waterproof and provides the maximum necessary buoyancy force due to its internal capacity; to this end, it is made of the metal that is most resistant to compression. This hydrostat is fixed above the helmet and in the vertical axis: it serves to balance the weight of the suit and that of the displaced volume of water. The cable will be attached to the hydrostat instead of the helmet. If necessary, the suit can be equipped with several compensating hydrostats. It is therefore in the interest of reducing the thickness of the suit to use metals that offer the best conditions for resistance, without forgetting those of corrosion resistance and ductility. The air necessary for the breathing of the diver is supplied by the pump of the manoeuvring boat; the air is supplied at a constant pressure, a little more than 760 millimetres of mercury and sufficient to remove the air polluted by the breathing of the diver. The air shall be admitted to the helmet by means of a flexible spiral metal tube of sufficient strength and leak-tightness. The detoxified air is expelled through a tube similar to the previous one and connected to the atmospheric sphere. A telephone establishes communication with the outside. Ascending and descending the suit is done by means of a flexible metal cable wound around a winch attached to the manoeuvring boat. The two air inlet and outlet tubes are also wound around a winch, each with a diameter sufficient to prevent damage. The construction details of this device will of course vary according to the applications. The attached drawings show, by way of example only, the following

Fig. 1 Longitudinal section of the diving suit showing the diver inside in front view.

Fig. 2 Front view of the suit.

Fig. 3 Longitudinal section (perpendicular to the one in Fig. 1) of the helmet covered with the compensating spherical hydrostat.

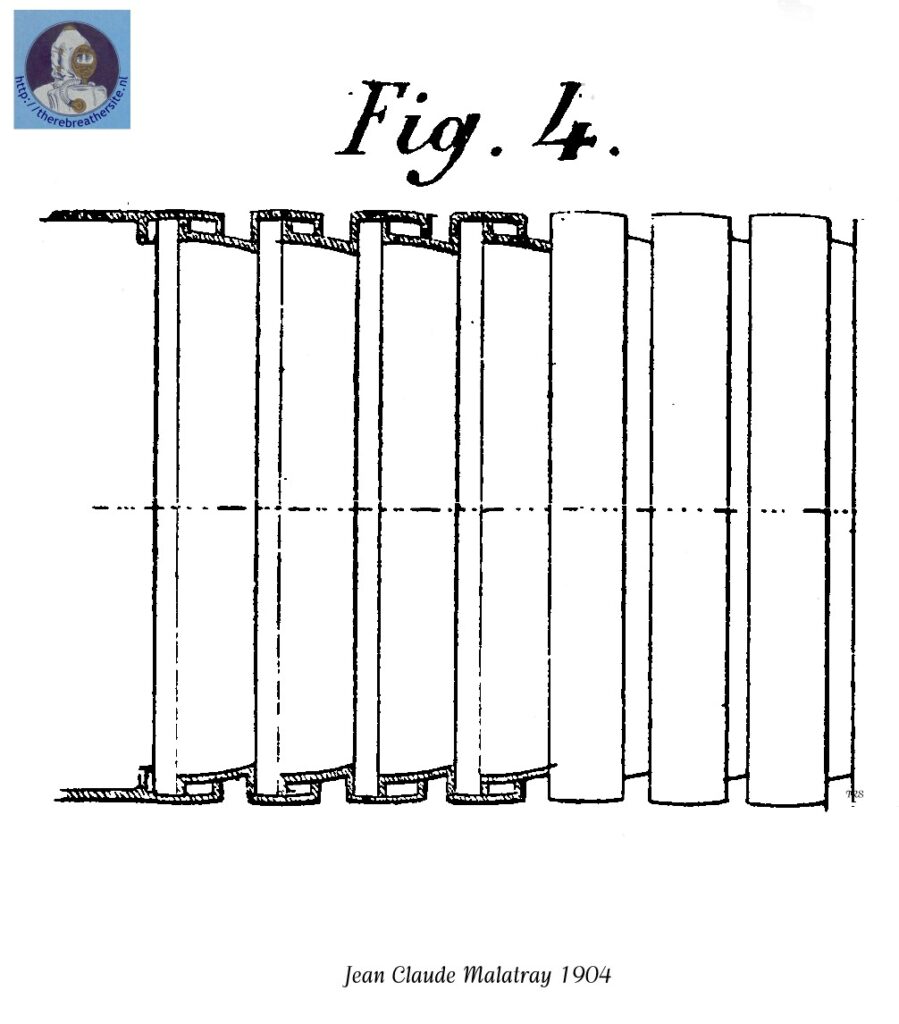

Fig. 4. Longitudinal section and elevation of an assembly of hinged parts.

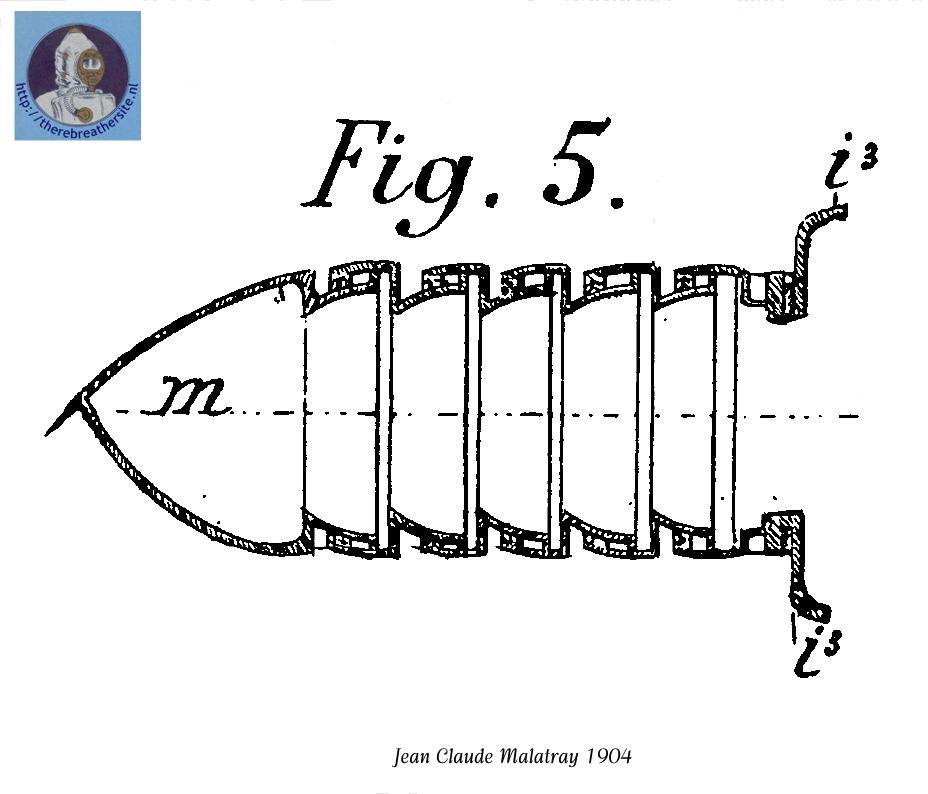

Fig. 5. longitudinal section of an articulated metal finger (specimen).

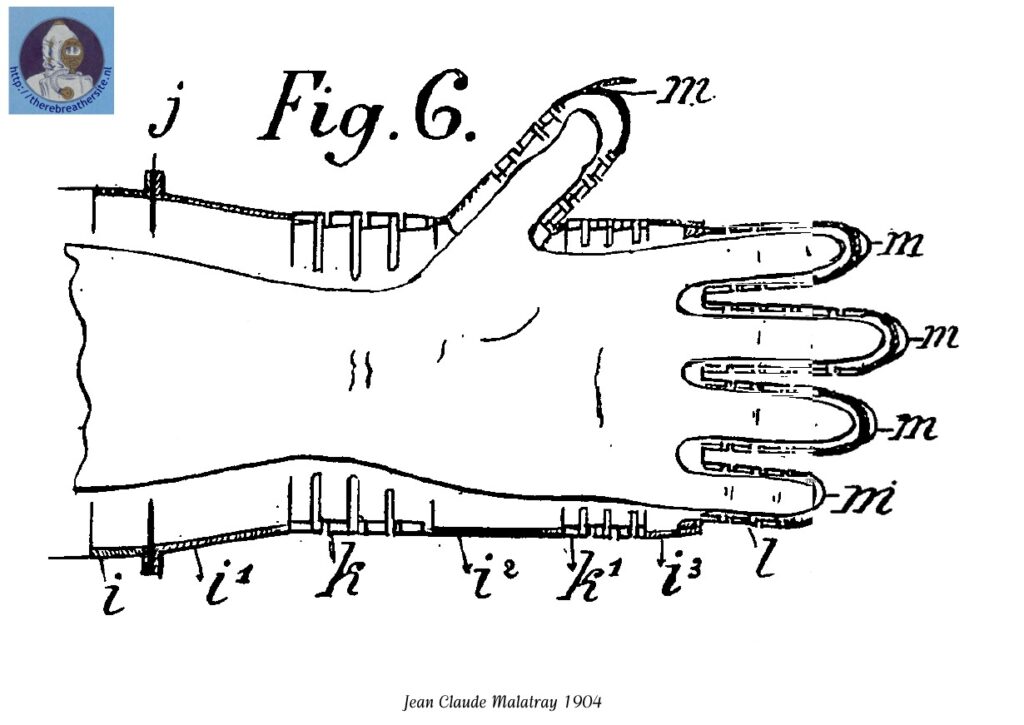

Fig. 6. longitudinal section representing the assembly of the articulated parts of the wrist of the hand and the fingers.

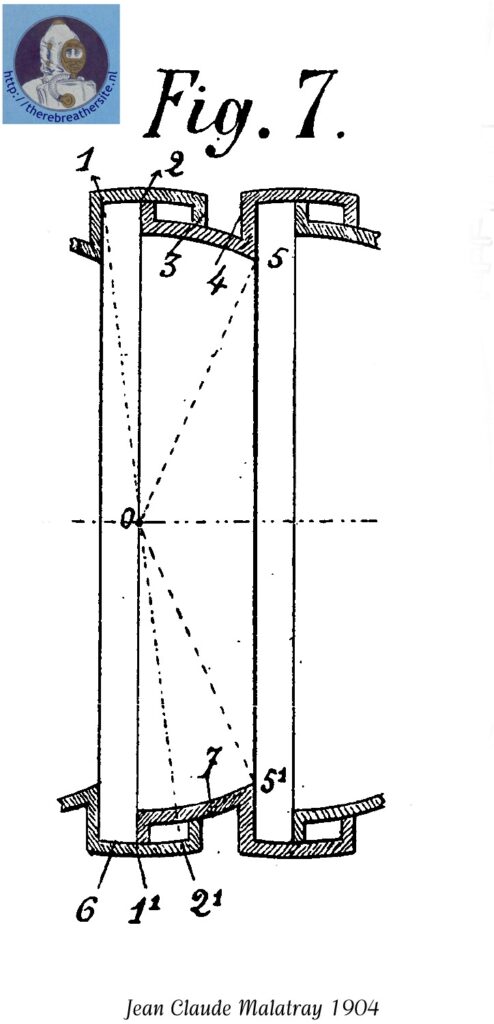

Fig, 7. schematic longitudinal section showing the set of articulated parts.

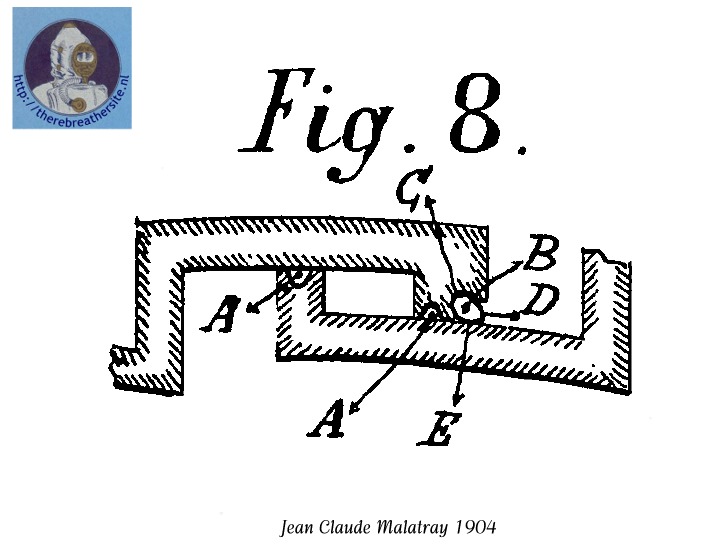

Fig. 8. schematic longitudinal section

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!