Lodner D. Philips was a man of varied talents. In his day and age he was known as one of the best under water engineers. He built a number of submarines and designed one that was steam-driven. He was a shoemaker from the United States son of Cyril and Virena Bateman Phillips, and born in the town of Perington (now Bushnell Basin). In 1856 he designed an atmospheric diving suit (ADS) for which he registered a patent.

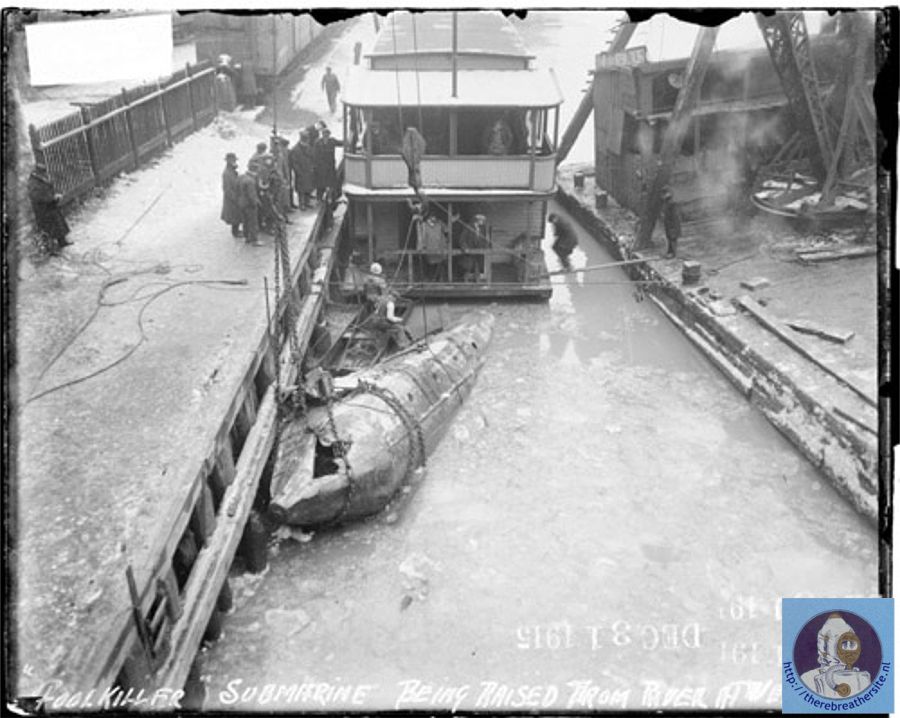

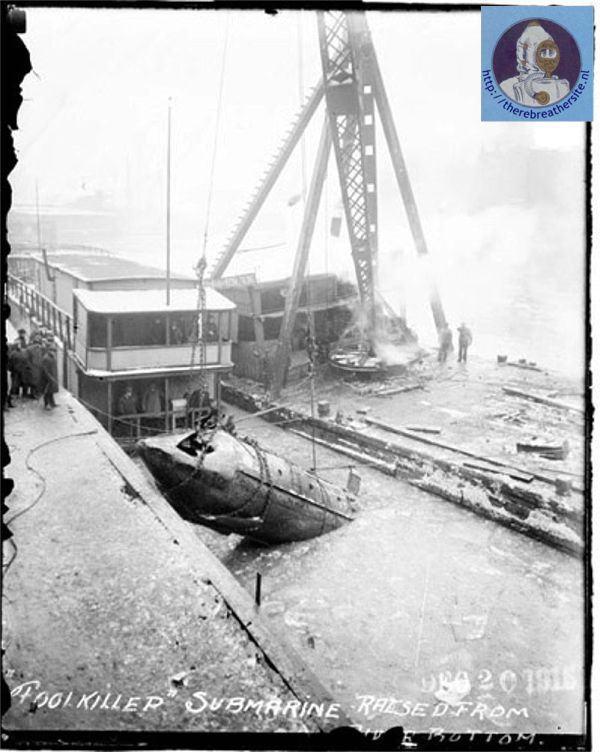

Picture published with permission of P.A. Gruse Harris, author of Great Lakes First Submarine Library of Congres number 82-073727

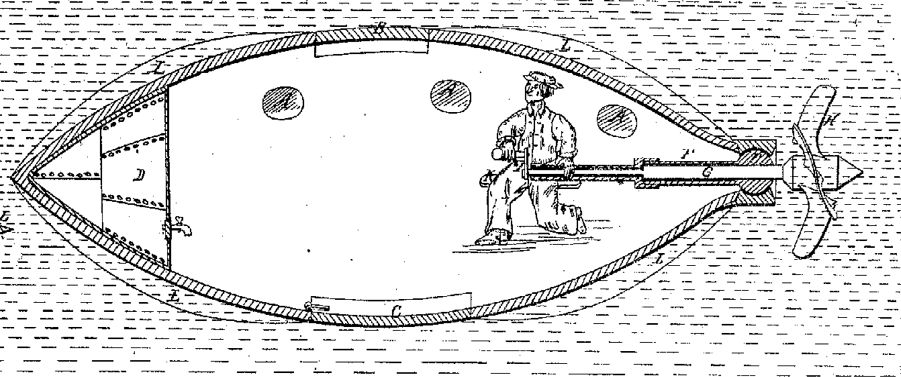

Besides his diving suit Phillips constructed a submarine that was hand-driven by means of a crankshaft.

Another submarine was tested to a depth of 33 meter.

He sold the submarine. The new owner however, was found drowned in his submarine in the company of his dog.

Phillips had offered his inventions to the Royal Navy.

However, they twice turned down his offer.

This made Phillips decide to stop the construction and designing of submarines.

There is no certainty as to whether the second submarine that he designed has ever been built and if it could indeed stay under water for 20 hours.

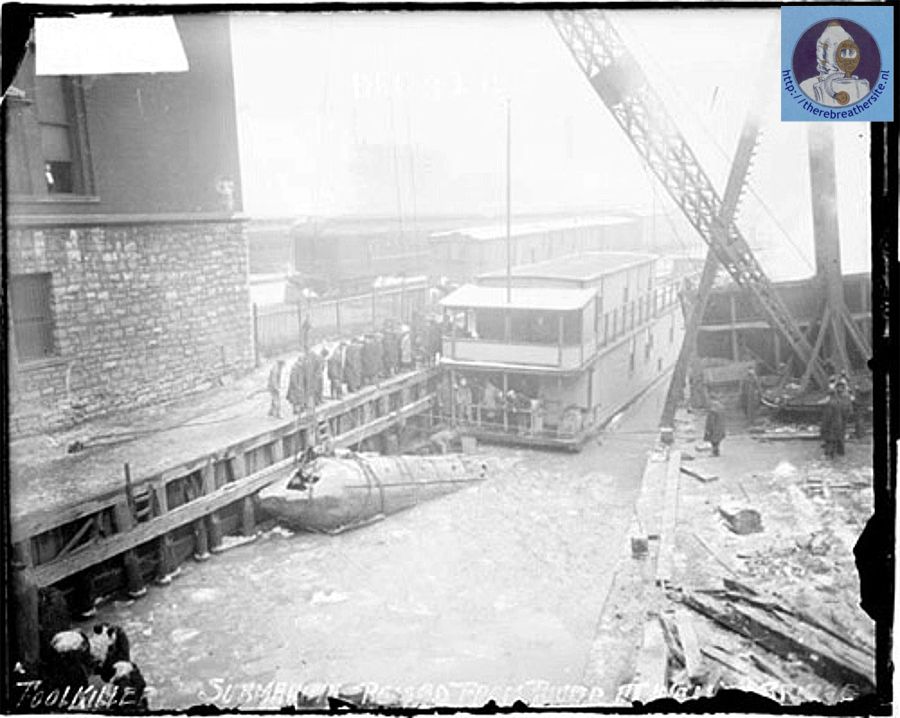

In the Chicago Daily News archieve there are some photos showing a submarine that could have been a Phillips design, but there is no clear evidence…. the pictures are beautifull, so please enjoy. If you have more information, please let me know!

Apart from diving related inventions Philips also designed other products. For example he designed a hose coupling (US. Pat. 16450) and a trowel ( US. Pat 16021). However, these are less important to me.

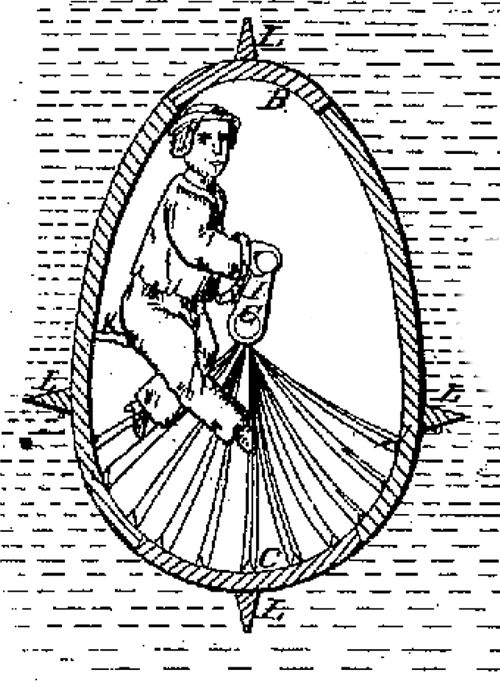

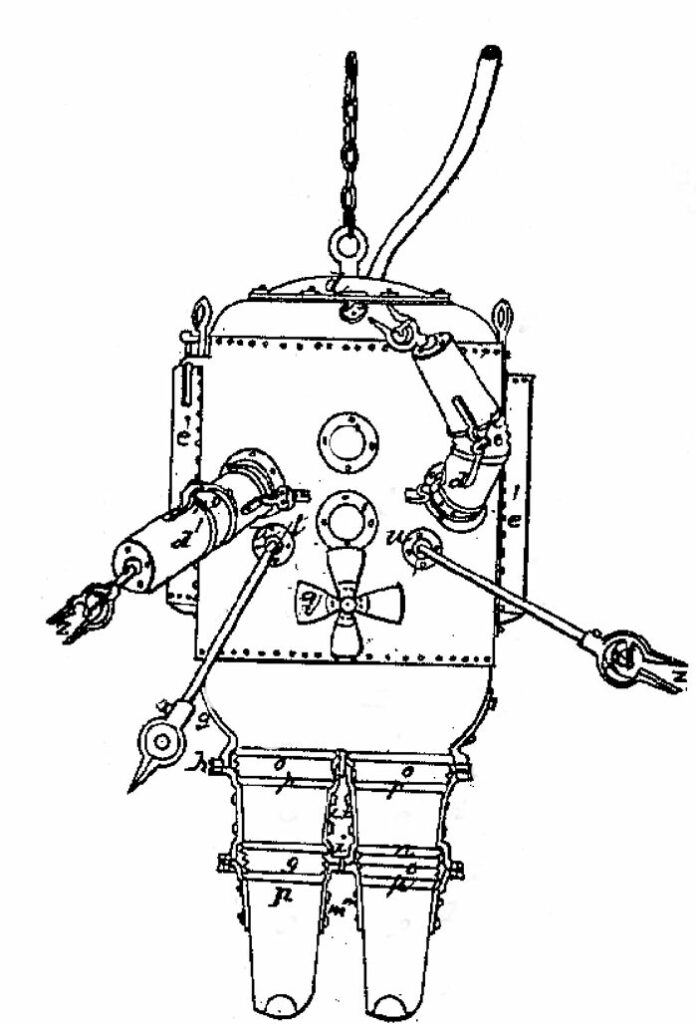

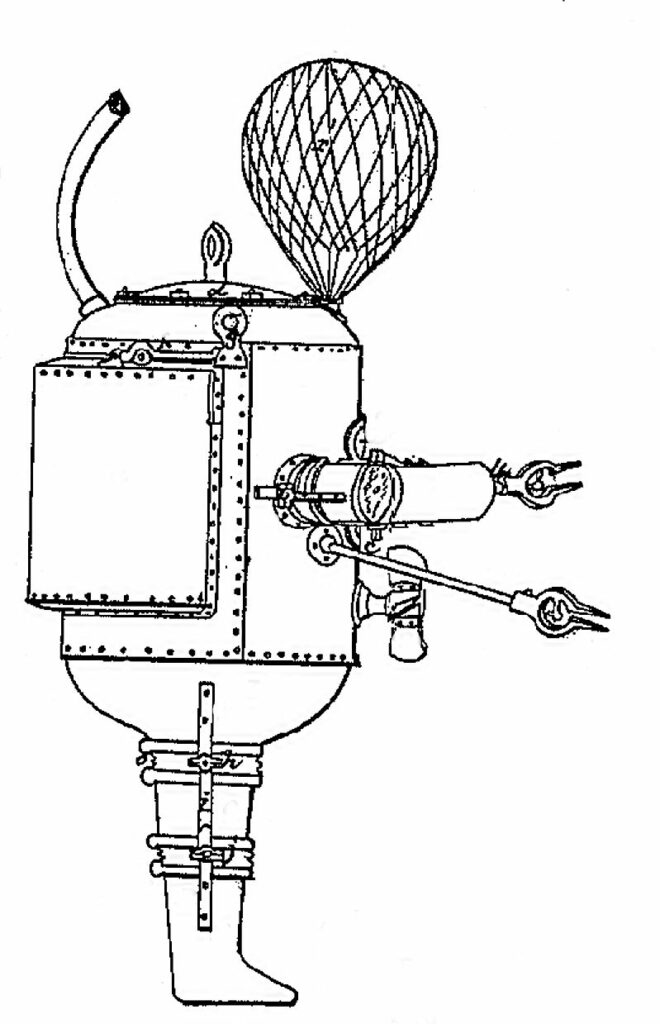

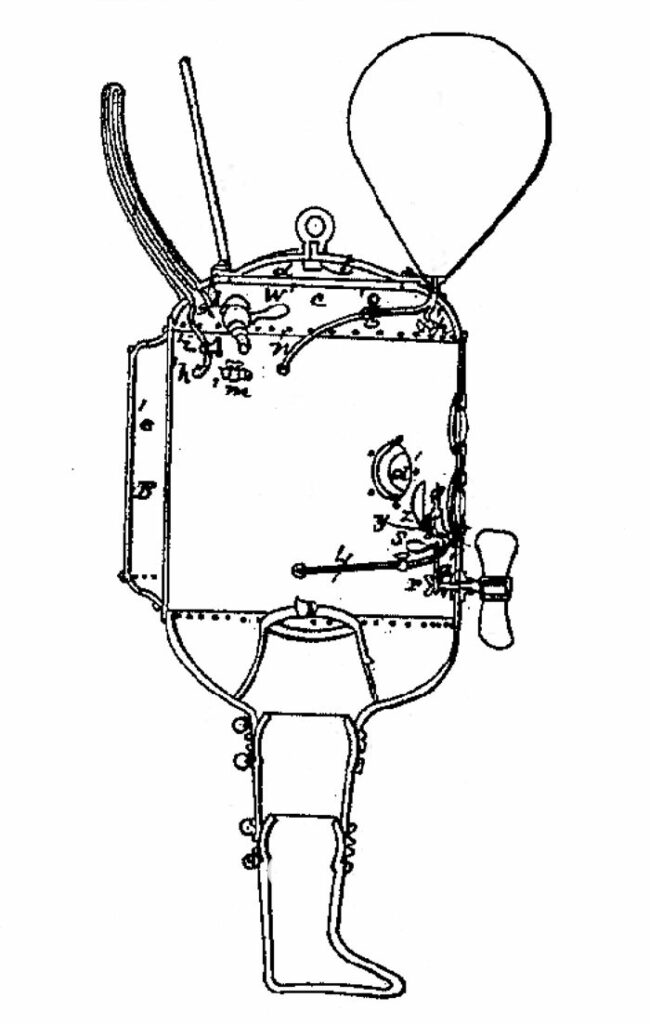

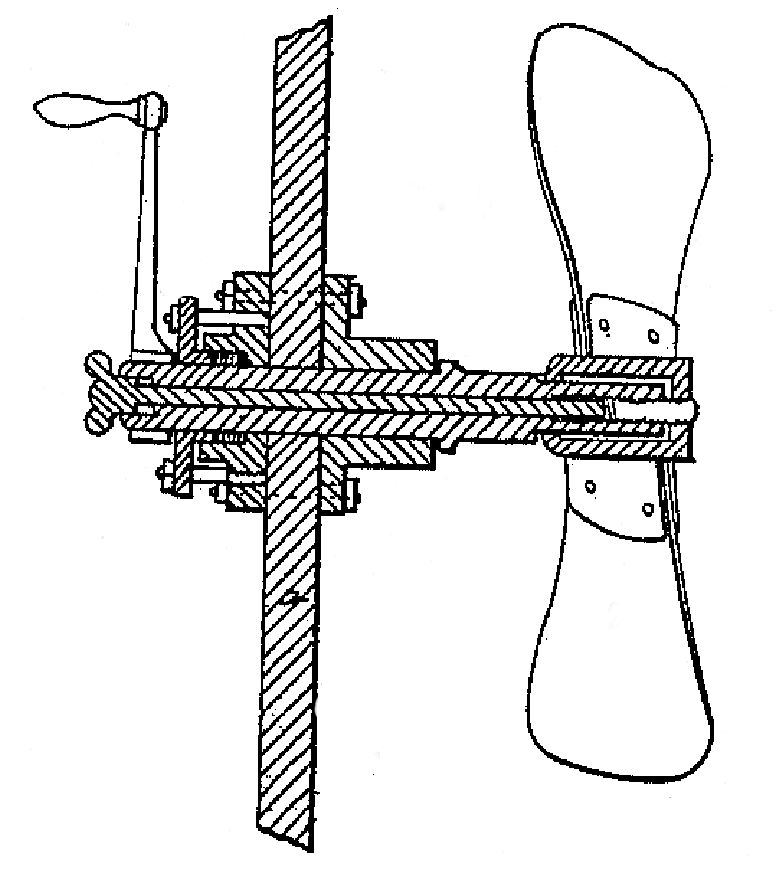

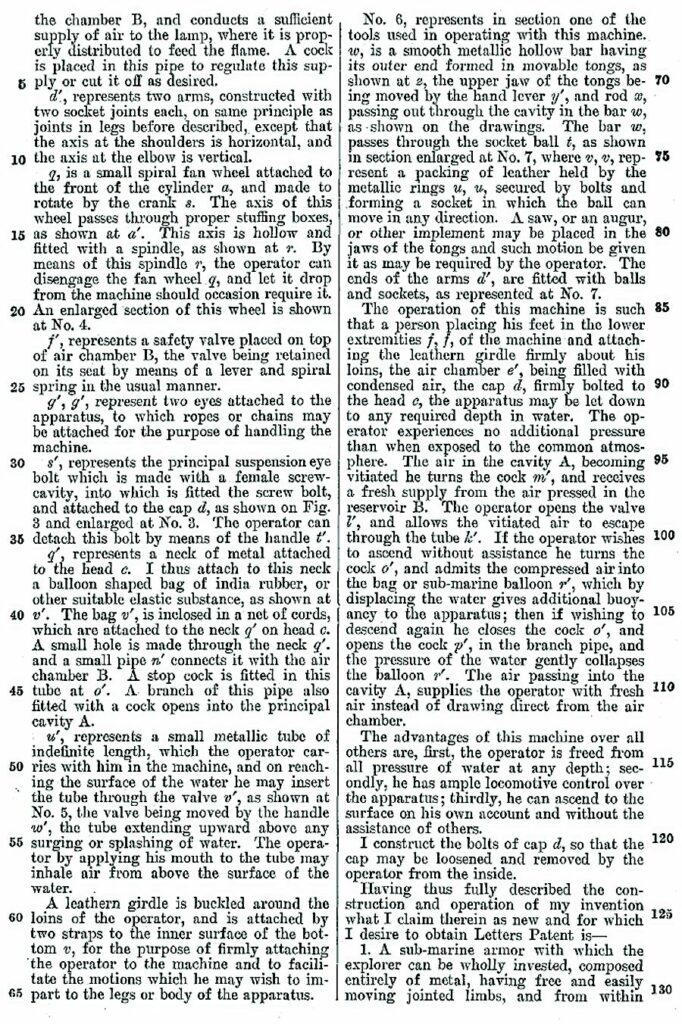

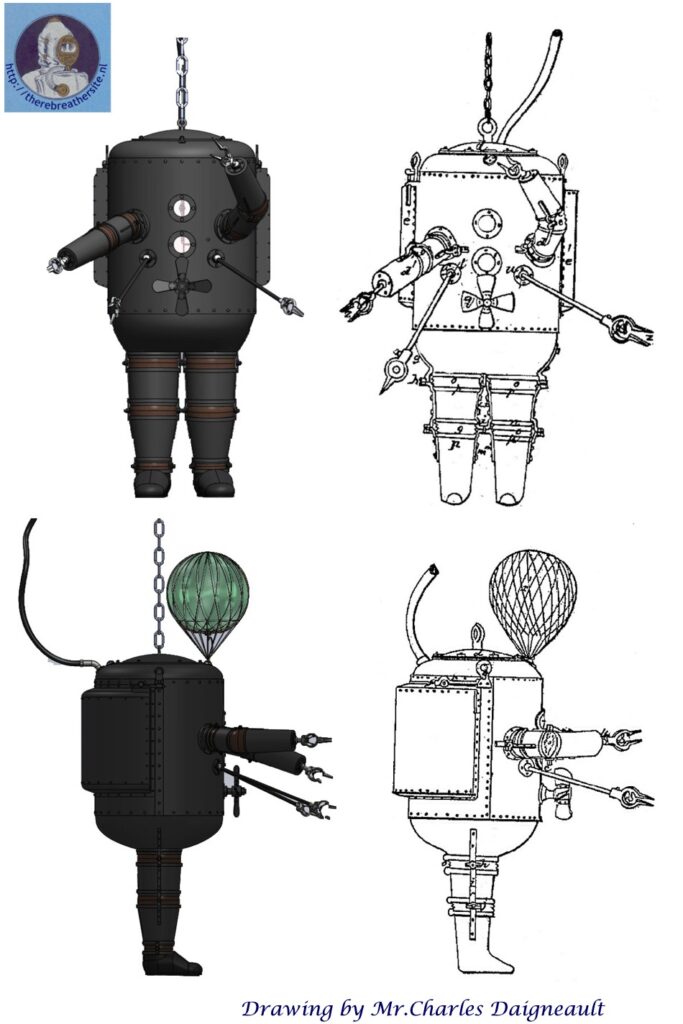

Lodner Phillips designed an atmospheric diving suit where we see the ball and socket joint applied for the first time.

This makes the design unique and very modern for it’s time.

In various descriptions you will find many elements of his diving suit, although many descriptions are incomplete or not very precise.

Phillips’ atmospheric diving suit is partly made of steal and partly made of cast iron.

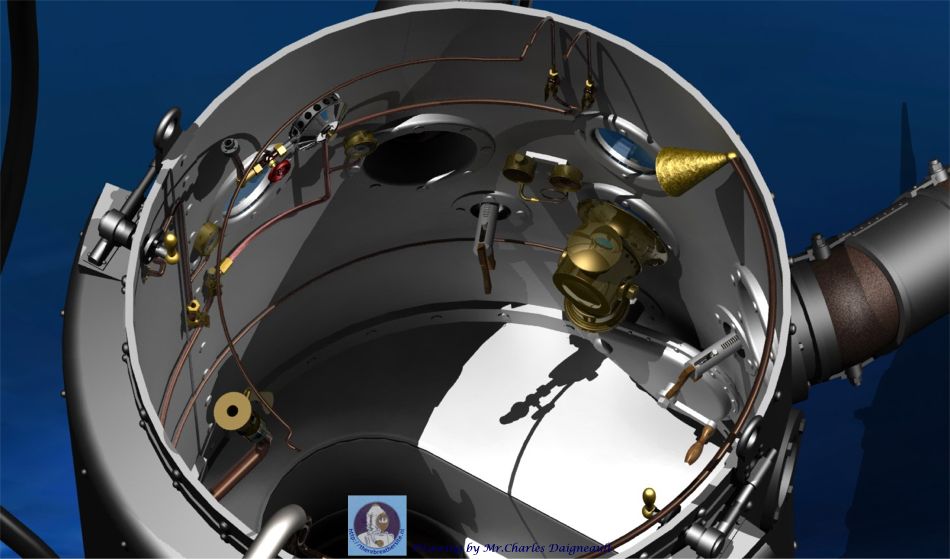

On top of the suit there is a bolted lid that is to be closed with a leather or india rubber gasket.

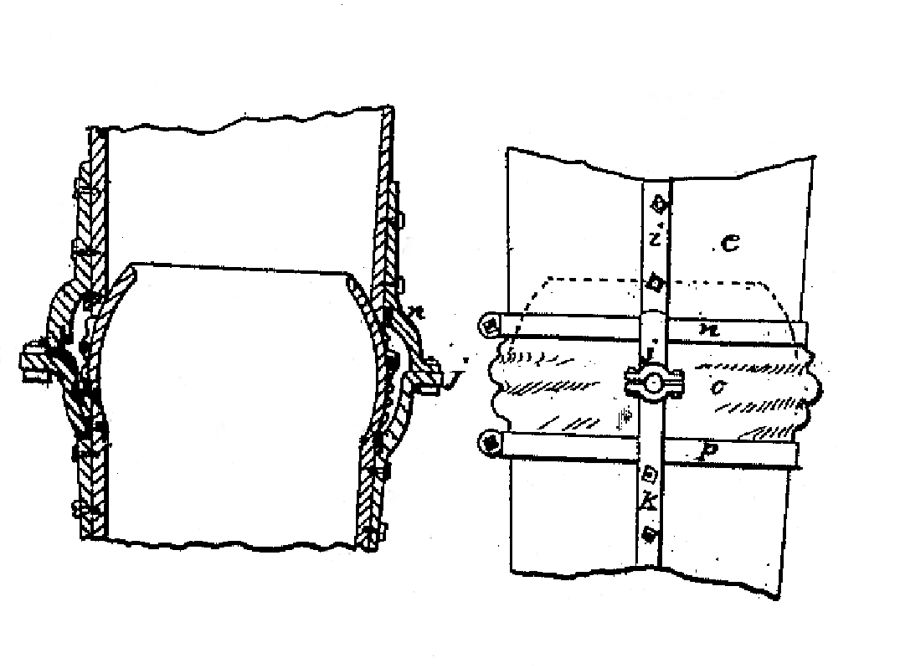

The joints were enveloped by a rubber ring secured above and below the joints by hoops.

These hoops had their ends flanged and were drawn tight with a screw bolt in the usual manner.

At the back of the suit a concentric formed cylinder is installed. This cylinder is made from boiler steel.

This cylinder can contain highly compressed air.

This compressed air cylinder is in many descriptions unjustly referred to as trim vessel.

The suit has a double hose that has a pressure resistant shell.

At the surface a pressure pump was used to transport air to the suit.

The return hose was also used to send sound signals to the surface, one could shout from the suit to the surface.

At the front of the suit there are two plano-convex lenses.

The upper lens is serving as a window for the suit-operator/diver????

The lower lens has a gas light behind it.

This gas light uses oxygen that comes from the back placed cylinder/vessel.

The suit is equipped with joints on the hips, knees, shoulders and elbows.

The shoulder joints move in horizontal direction and the elbow joints in vertical direction.

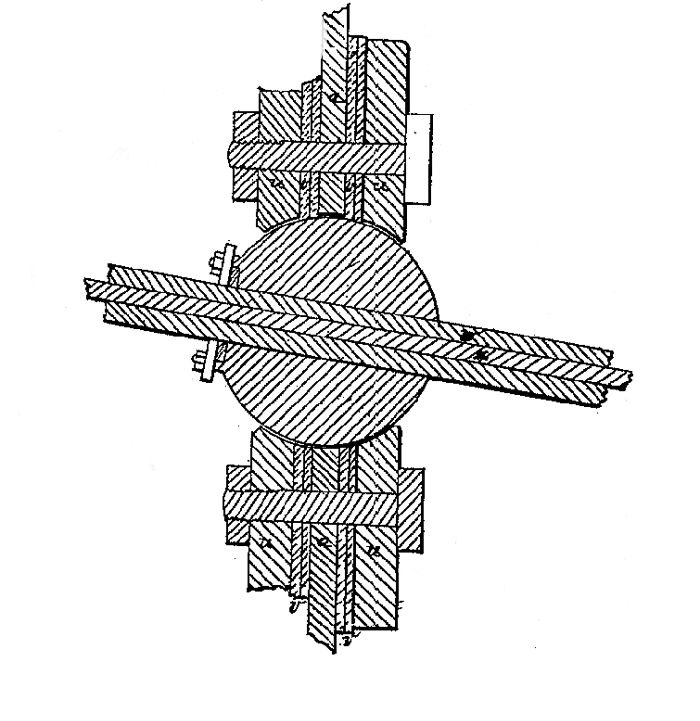

At the front of the suit is a propeller for the purpose of impulsion.

The suit was hand-driven. In case the propeller got stuck, the operator could unlock it via a hollow axis in the inside of the suit und thus disconnect the propeller from the suit.

At the top of the suit there is a depressurizing valve.

At the left-hand and right-hand side there are two lifting eyes in order to manoeuvre the suit with a rope or a chain.

At the top a central eye has been placed which can be used to lower the suit in the water.

In it’s inner circle this eye has a construction that allows the diver to disconnect it from the suit in case of an emergency.

Inside the suit a small metal inhalation tube is present. This enables the operator to breath when at surface.

The tube has to be pushed outside for this purpose.

The operator is hanging in a leather jacket inside the suit and is strapped in so that he can develop strength in his movements.

The arms have grippers that can contain various tools.

This tools are being operated from the inside out by operating handles.

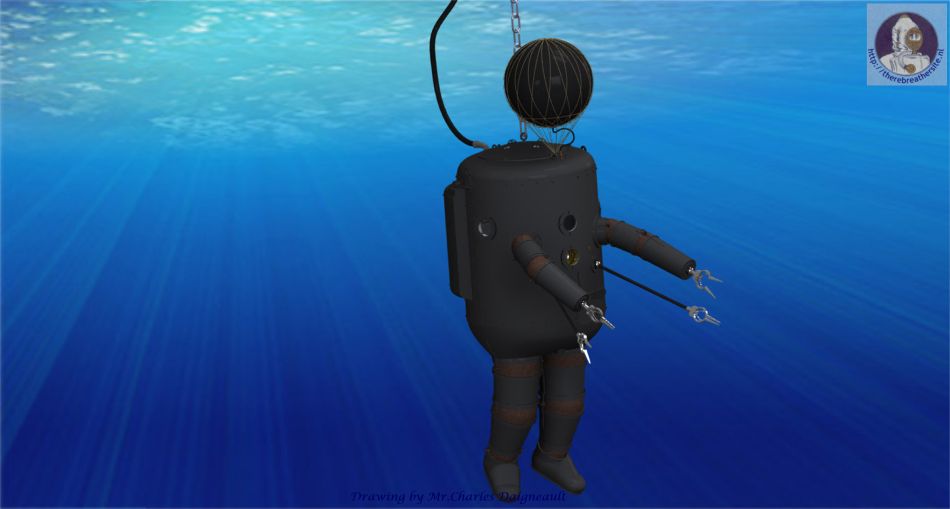

The operator takes up his position in the suit and is being sunk down to a certain depth.

If he wishes he can let in additional air from the supply that is present in the cylinder on his back.

Should he so desire he can ascend independently. He can inflate a balloon that is on top of his suit via the cylinder at his back, thus enlarging his lifting ability and his ability to ascend autonomously.

If this suit was ever made or it was ever used remains unclear to date.

The way this suit was designed would make it hardly possible for the joints to move under high pressure.

Remarkable for it’s time is the use of joints and the great attention for the safety of the diver.

Since it is suspected that diving suits could not reach depths much deeper than 30-40 meter the construction with the bail out balloon seems plausible.

Finally Phillips is an inventor who had much knowledge of buoyancy systems since he designed various submarines that were factually built.

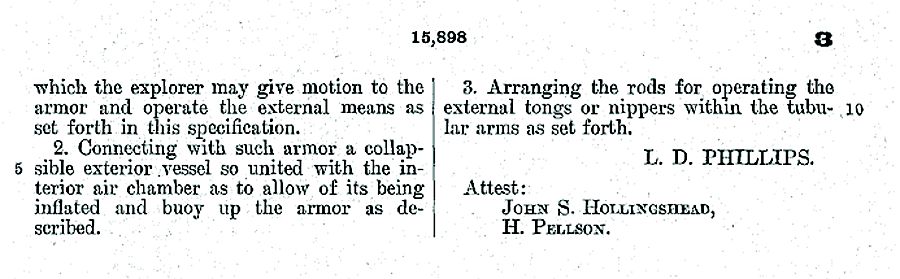

You can read or study the complete patent 15898 here.

| Literature: There is a fantastic book written by Patricia A. Gruse Harris called “Great Lakes First Submarine” L.D. Phillips, “Fool Killer” copyright 1982, library of congress Number 82-073727 U.S. Patent: 9389; SubmarineU.S. Patent 15898 Atmospheric diving suitU.S. Patent 16021 TrowelU.S. Patent 16450 Hose couplingU.S. Patent 60053 Buttons Making machine |

| A special thanks to Patricia A. Gruse Harris for her kind cooperation and hard work collecting all data about Phillips. |

| All pictures information or other information related to Lodner Darvontis Phillips is most welcome! |

| added 26-6-2009 this article from the Cleveland Plain dealer |

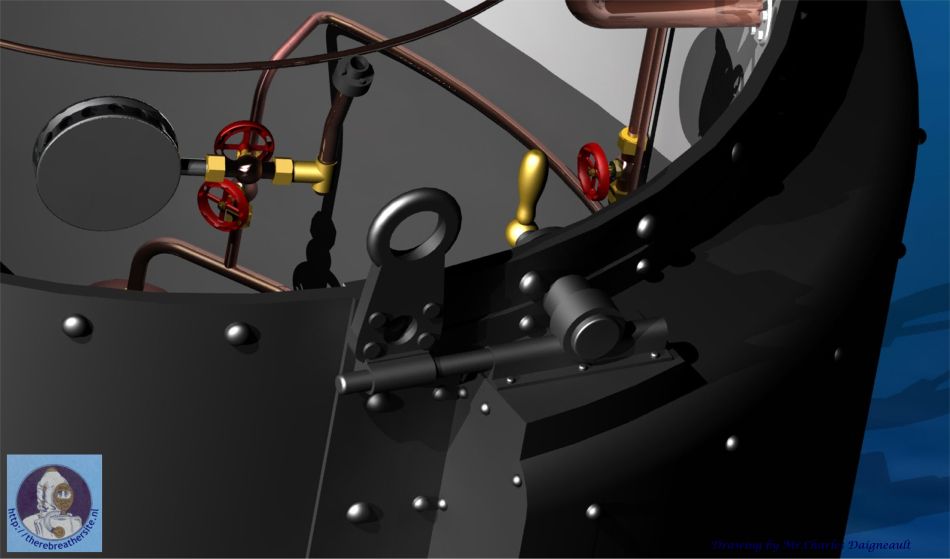

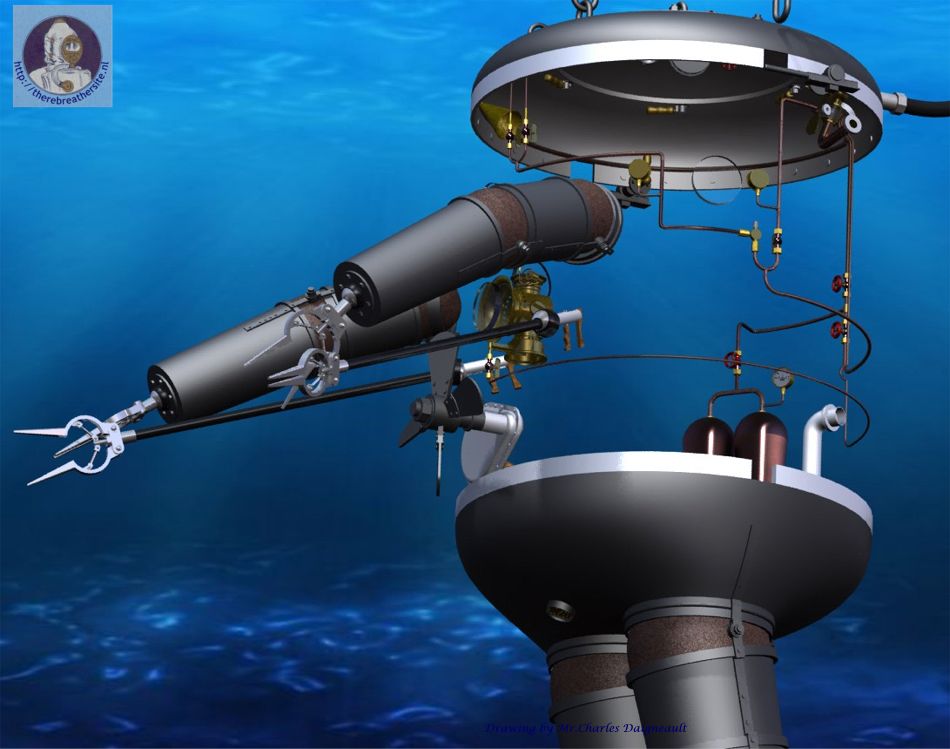

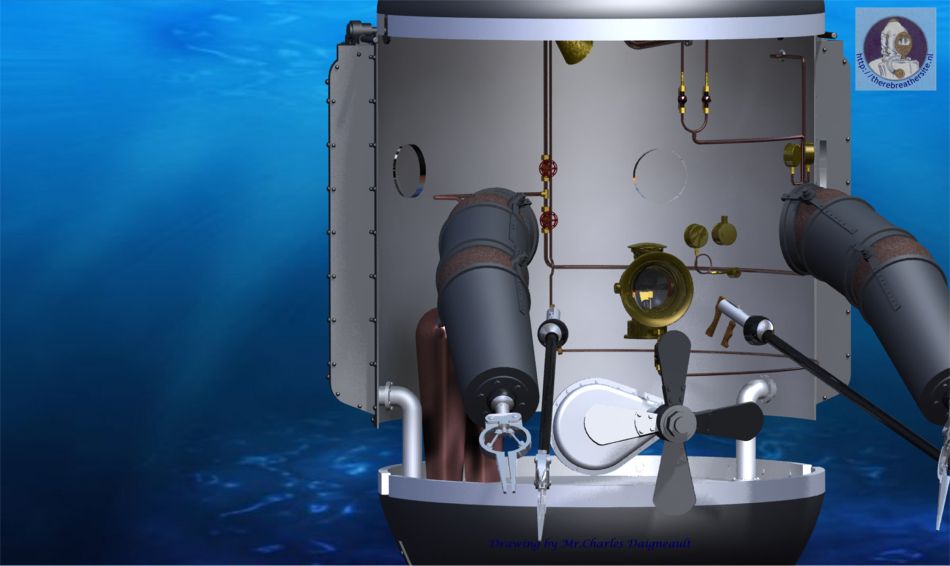

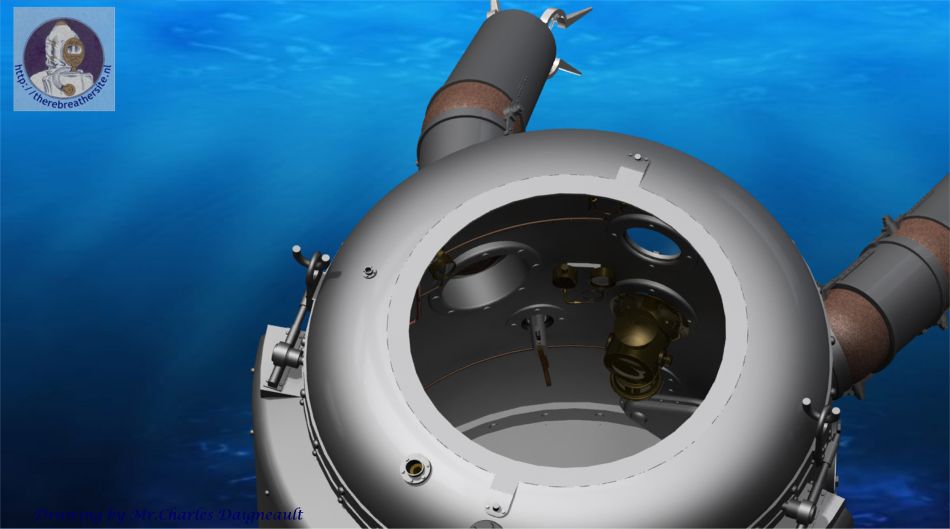

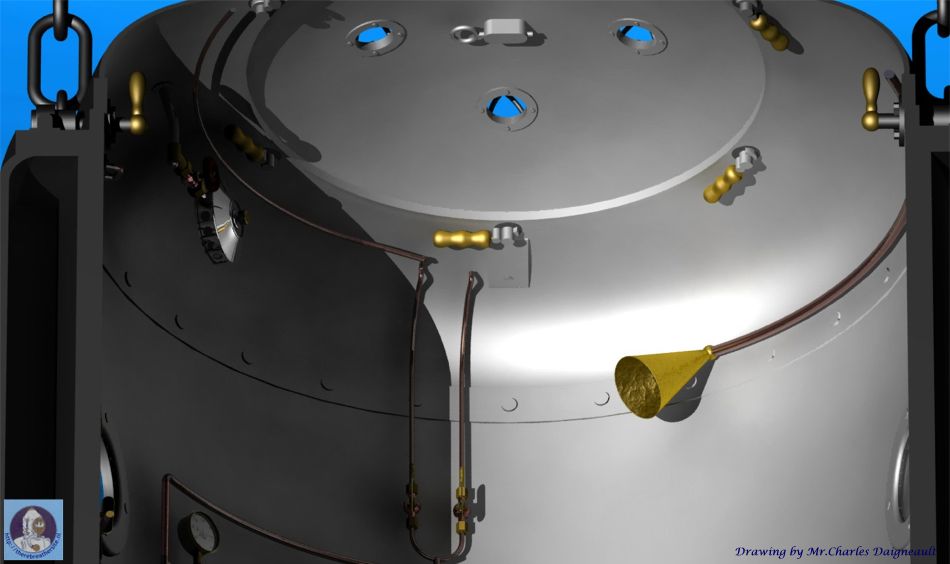

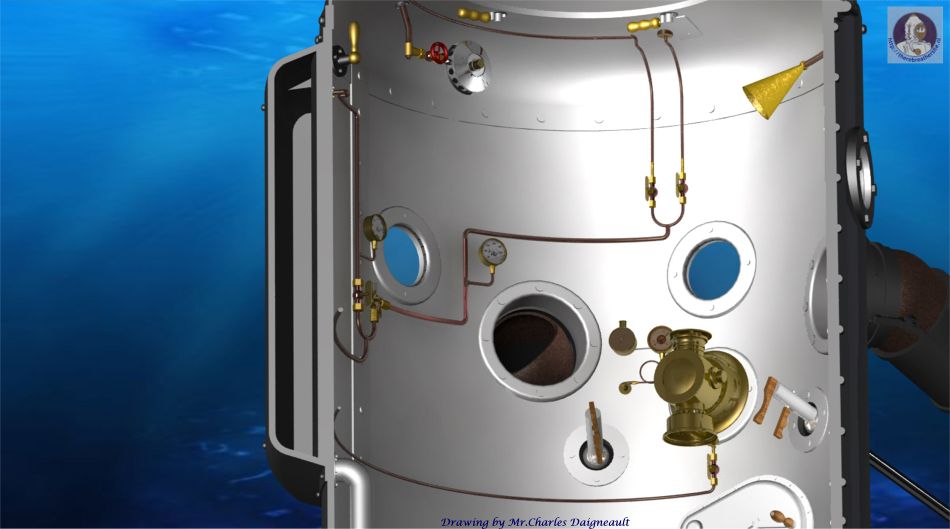

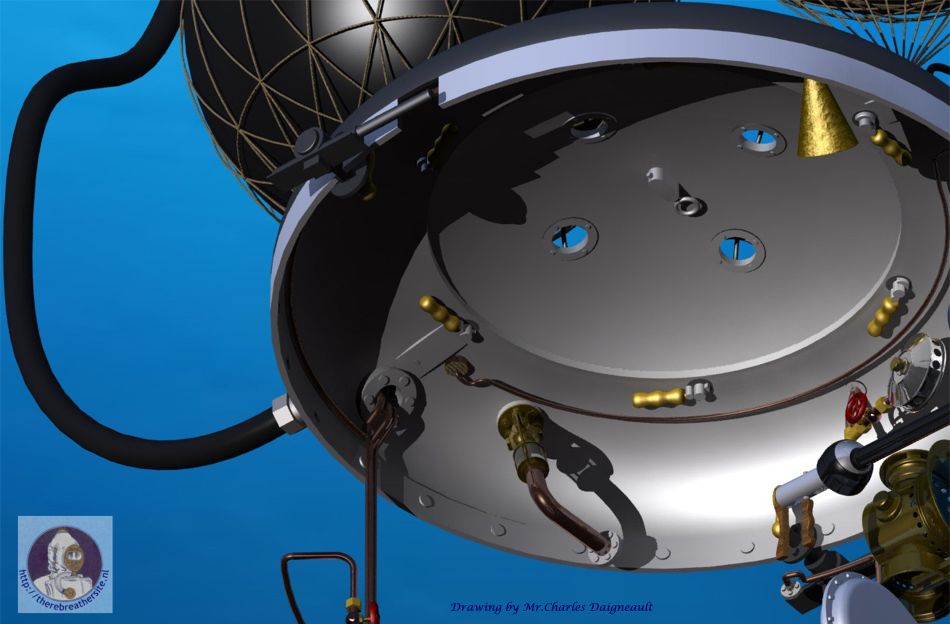

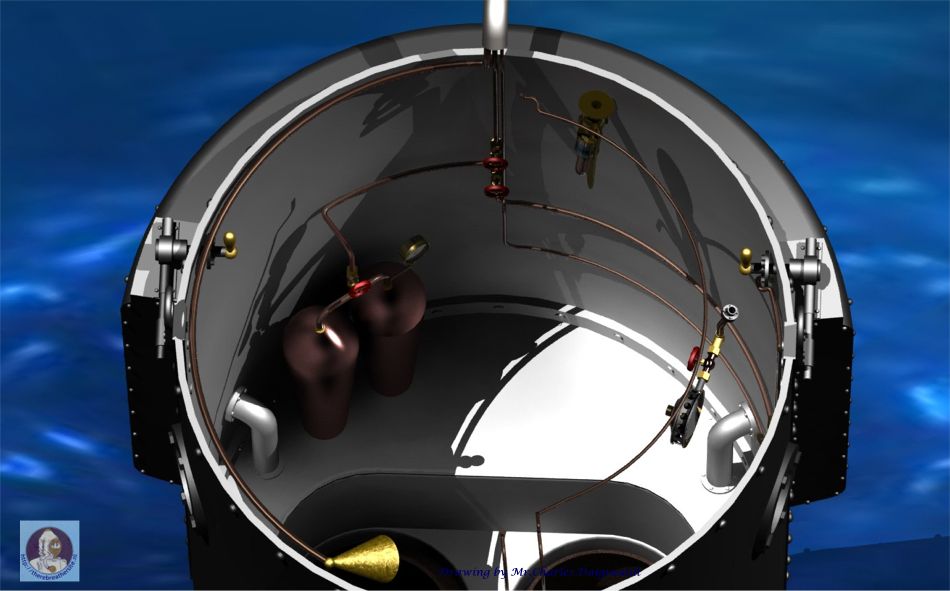

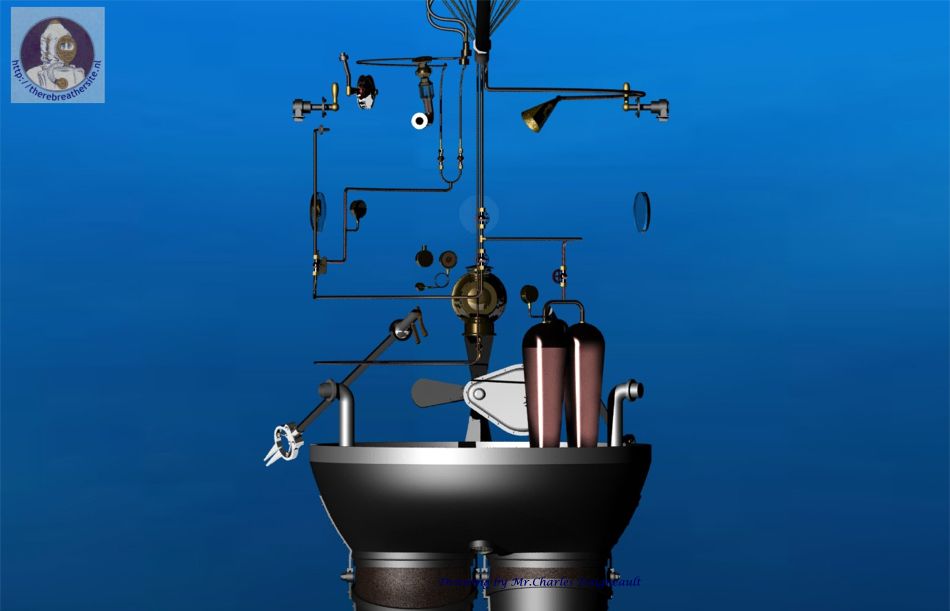

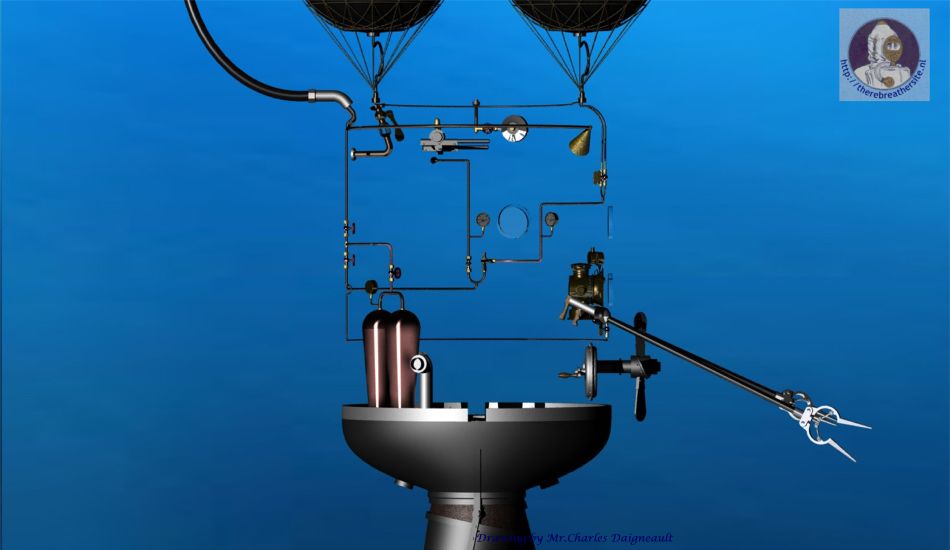

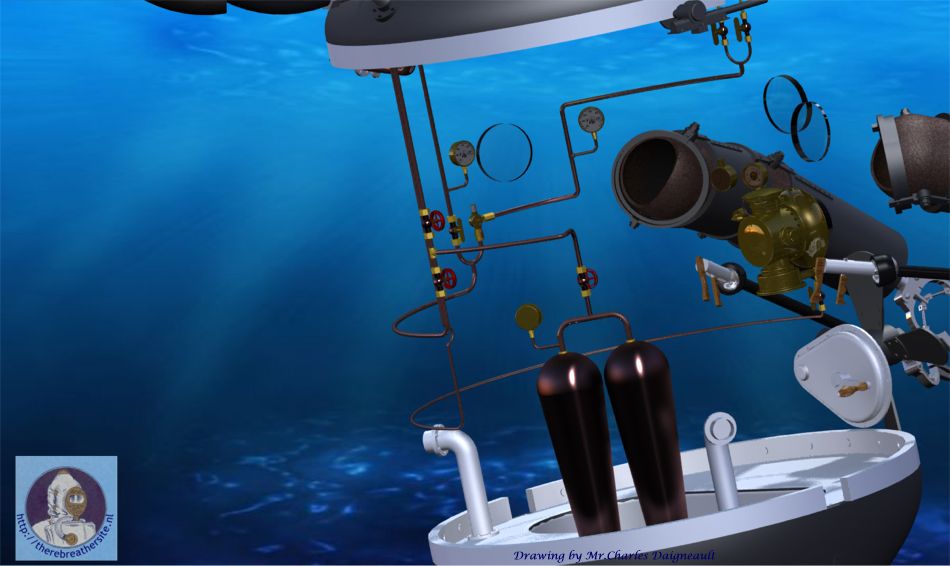

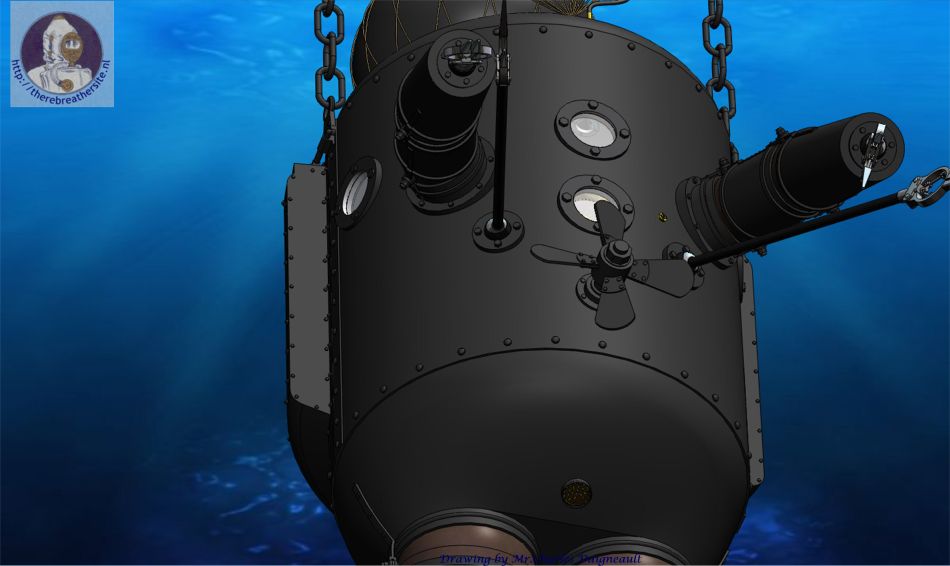

Charles Daigneault’s ART WORK

Dear Mr. Bech,

It has been a long time indeed, but as promised, I have prepared a new 3d model for therebreathersite.nl historic A.D.S. section, so attached you will find some images of the Lodner Philips rig. I must confess I chose Mr Lodner Philips design because I thought at first it would be an easy assignment, after all, what is difficult in a cylinder with arms and legs. boy was I ever wrong! What was supposed to be an easy model turned into a long term research project and an incursion into Mr. Philips imaginative mind. I could not be content with a simple reproduction of the patent drawings. I asked myself what if they did really built it? In a leap of imagination I wondered how would this design turn out if a late Victorian top-of-the line craftsman had picked up Mr. Philips patent and actually built a working prototype using 19th century boiler and steam engine technology? I got engrossed in the idea and started modeling what might have been.

Mr. Philips was a precursor, his design had some features that are still in use today in state-of-the-art underwater technology like thrusters, high intensity lighting, inflatable lift bags, communication apparatus and manipulator arms. Unfortunately he seems to have lost interest in the middle of his design process and rushed to finish his drawings leaving numerous details vague, abset or unexplained. Also I had to face the same challenges he did to design a practical a.d.s. While in the process, I realised the numerous technical difficulties that needed to be overcome for such a design to become (maybe) a workable diving machine instead of being a gruesome death-trap. Some failings became immediately evident, the most obvious, being because the shell is basically an empty cylinder, it would never had been able to submerge, it would simply have flipped on it’s side and floated away thus the need for ballast, the incomprehensible backpack took a new meaning under this assumption, I think it would have proved inefficient as a compressed air tank, so turn it into a ballast tank and put period “air flasks” inside and also turn the whole lower portion, the large “pants” into part of a complex dual ballast system with intake, fill control valve and compressed air purge valve. The lamp would have used acetylene, not oxygen, the gas being fed from the surface, looks very dangerous thought, and there is the strong possibility, the diver/operator might have cinged his beard while looking out the upper porthole! A part reference number on the front patent drawing left side relates to he incomprehensible device located on the top of the backpack right side, I concluded this is a lock-release for the right and left side lift hooks, the builder might have realised it was not such a good idea to lift the heavy machine by the hatch cover only, better use a spreader bar for hoisting even if a center lift eye watertight lock- release is provided , and while we are at it, provide latch dogs in the inside so the operator can exit in case of the inevitable emergency, and two side-looking and top cover portholes , the necessity of which Mr. Philips seems to have overlooked. Also add a spur gear and pinion to the propeller for efficiency. . Now because of the work done by hardhats divers in deep-sea salvage and also by bridge construction workers during the 19th century, our Victorian era engineer would have had an inkling of the problems related to pressure and pressurised environments, thus an automatic pressure regulator with manual override is fitted to maintain a 1 atmosphere relative pressure. A “Christmas tree” manifold with spherical valves is to be used to manage compressed air between the air tanks and surface feed, pressure is further used for lift bags and ballast purge. Now about the watertight articulated joints, the vague patent drawings clearly shows they would never have worked as designed. This A.D.S. is destined to become a rigid observation tower under a few meters, except for the manipulators which might have been usable, unfortunately the water-proofing technology necessary to accomplish this, like o-rings, was not yet invented, so every joint would have leaked badly, even with the addition of a bilge pump, it is evident the whole rig would have proven unusable, but as this is an imaginary prototype, let’s provide spherical and rotary watertight joints along with the reinforcing hinges to attain some degree of mobility. What about the annoying lift-bag? Well maybe our engineer would have installed two instead of a single one and controlled them separately for inflation and deflation, maybe a skilled diver would be able to tilt front to back by adjusting the bag’s air pressure differently with two separate valves and purge, finally depth and air pressure gauges would complete the fittings of this primitive device. All that is missing is a CO2 scrubber and you have a 19th century a.d.s! After completing this project, I was left with many unanswered questions, Which is perfectly normal when dealing with a concept that is over 100 years old! In all, it was for me an interesting and fun experience. I am sending you some .JPG shots of the resulting model, I would be honoured if you decided to post them on your website. I also added some “artsy” illustration type renderings in art deco style, but I am not sure they have their place on therebreathersite.nl I included them mainly for your personal enjoyment. Unfortunately I was unable to produce a satisfactory .AVI file, the results proved very disappointing , In the future I will have to use a different software than Solidworks for this purpose to obtain an enjoyable and realistic animation. There you have it Mr. Bech, It took some time but I did it, now I have to move on to another project, but I plan to make another historical a.d.s. model in the coming months, I already decided which design I am going to tackle, but this is another story. In finishing, thank you very much for giving me the opportunity to interest you in my work. And I will, of course continue to explore and enjoy your great web site.

In the meantime, all my best wishes to you Mr. Bech.

Cheers.

Charles Daigneault.

A special thanks to Charles Daigneault for his exceptional work. It shows mastery of design when you are able to translate a patent drawing into a real-life model. The considerations in his introduction also contribute to an understanding of the complexity faced by engineers then and now. The sealing of these suits with pressure differences of tens of bars was and is an enormous challenge. The work that Charles put into these drawings contributes to a better understanding of how these atmospheric diving suits worked. On behalf of my visitors and myself a special thank you for this achievement!

Therebreathersite was founded by Jan Willem Bech in 1999. After a diving career of many years, he decided to start technical diving in 1999. He immediately noticed that at that time there was almost no website that contained the history of closed breathing systems. The start for the website led to a huge collection that offered about 1,300 pages of information until 2019. In 2019, a fresh start was made with the website now freely available online for everyone. Therebreathersite is a source of information for divers, researchers, technicians and students. I hope you enjoy browsing the content!